Apparatus and method for testing conductivity of battery diaphragm

A battery diaphragm and conductivity technology, which is applied in the direction of measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve problems such as complex operation, low test efficiency, and long test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

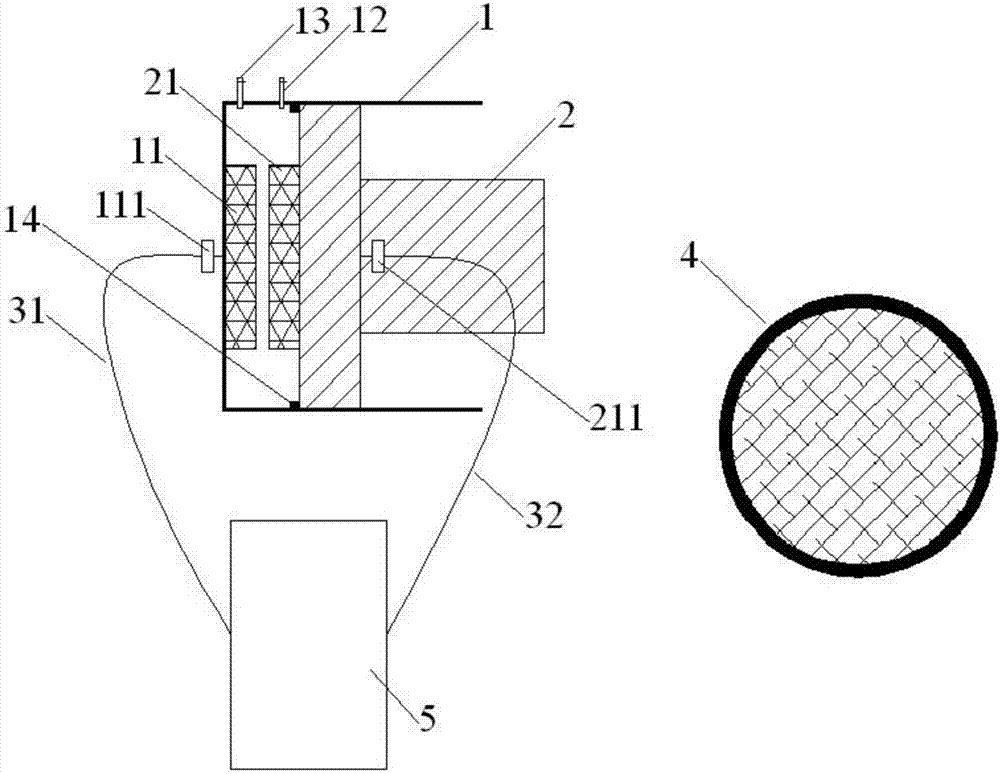

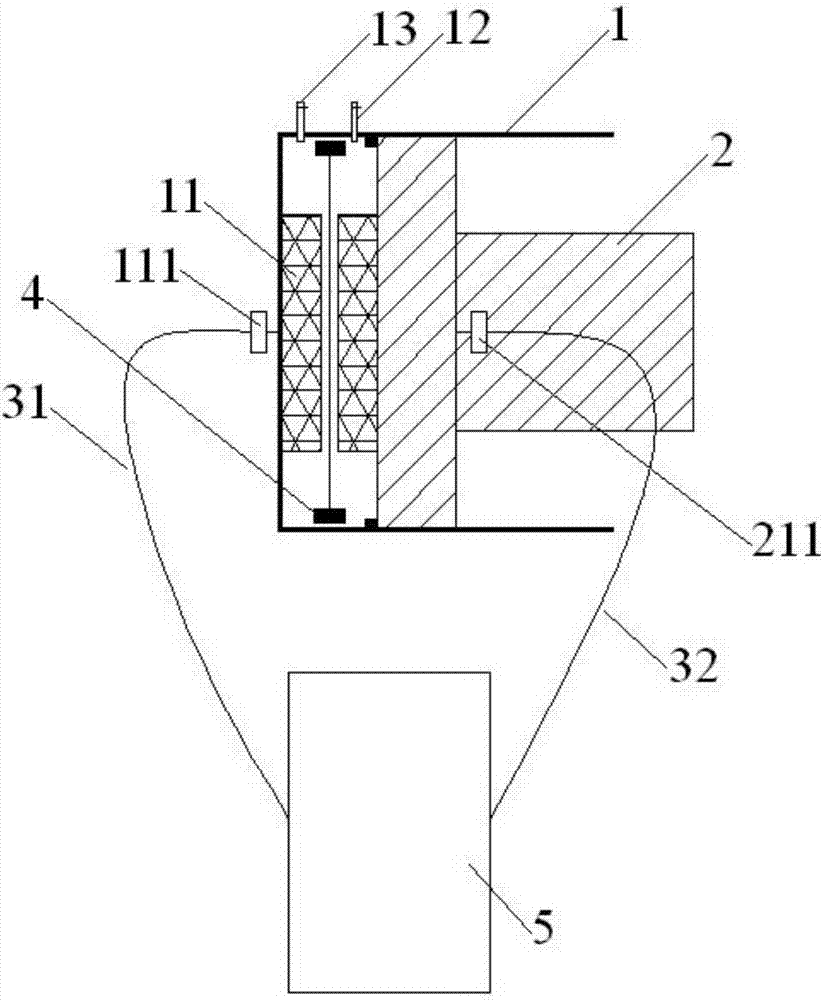

[0046] The battery diaphragm conductivity testing device of this example, such as figure 1 As shown, it includes a conductivity cell housing 1 , a conductivity cell cover 2 , a diaphragm clamp 4 and a conductivity meter 5 .

[0047] The conductance cell housing 1 is a cylindrical barrel-shaped structure with one end open. Inside the conductance cell housing 1, there is a first circular conductance electrode sheet 11 at the bottom end, and the outer surface of the bottom of the conductance cell housing 1 has a first electrode external interface 111. , the first electrode external interface 111 is connected to the first circular conductance electrode piece 11 by wire; the conductance cell cover 2 is disassembled and fixed on the open end of the conductance cell housing 1, and the conductance cell cover 2 is inserted into the conductance cell housing 1 to connect with it A relatively closed cavity is formed, the inner surface of the conductance cell cover 2 has a second circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com