Multiple Disc Clutch

A clutch and multi-disc technology, applied in the direction of clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of high cost and expensive manufacturing of multi-disc clutches, and achieve the effect of precise structure and saving axial installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

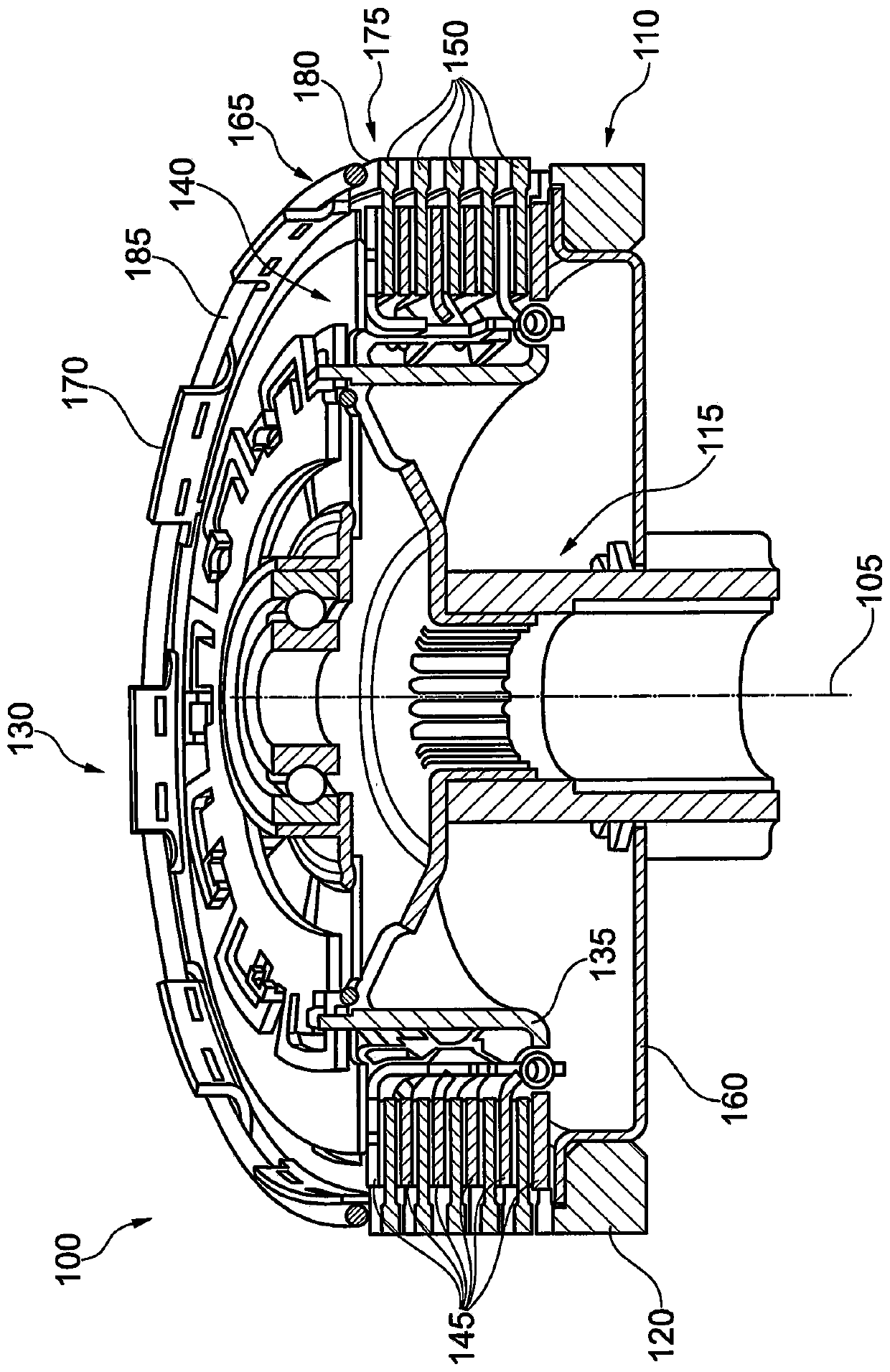

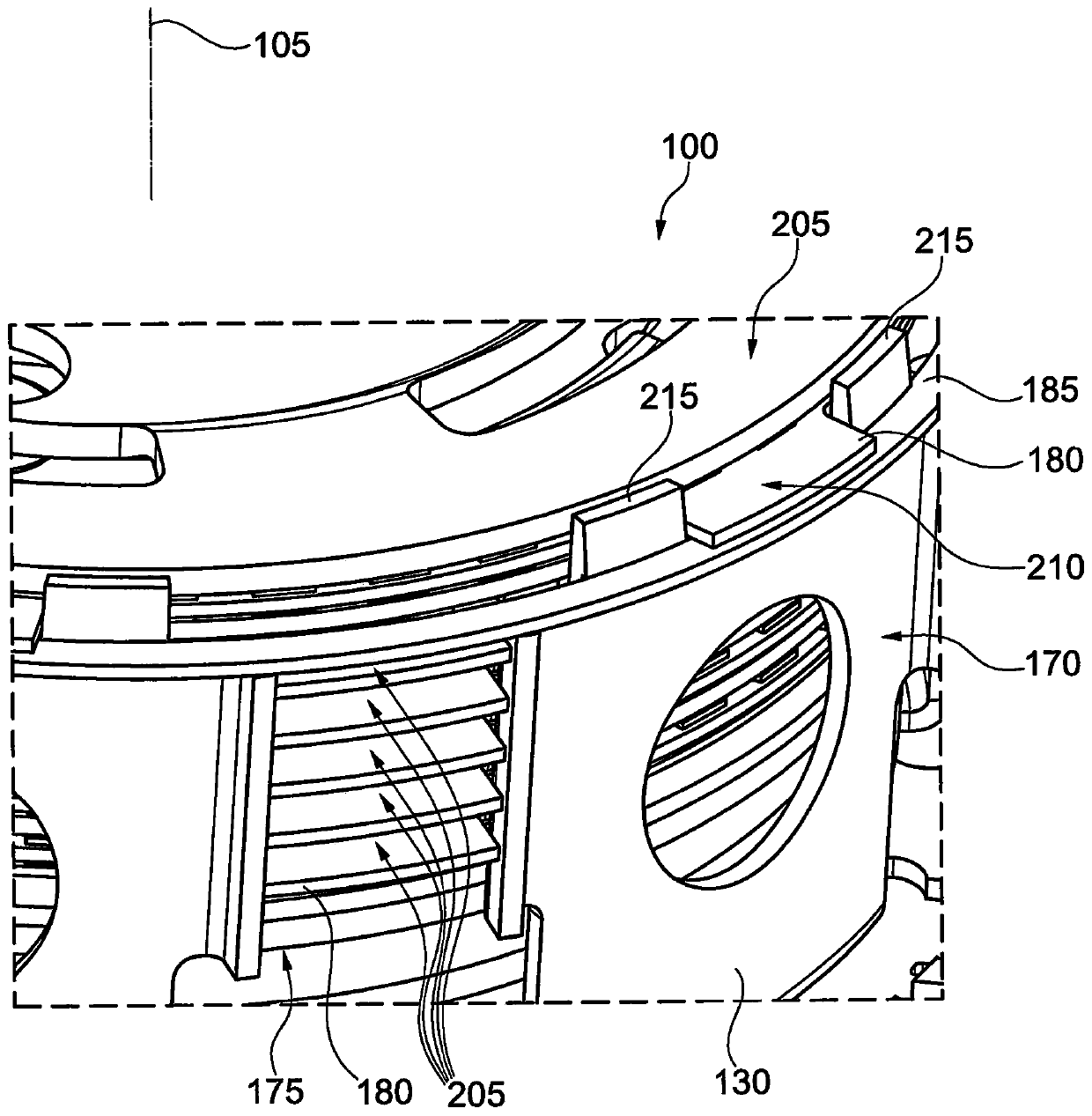

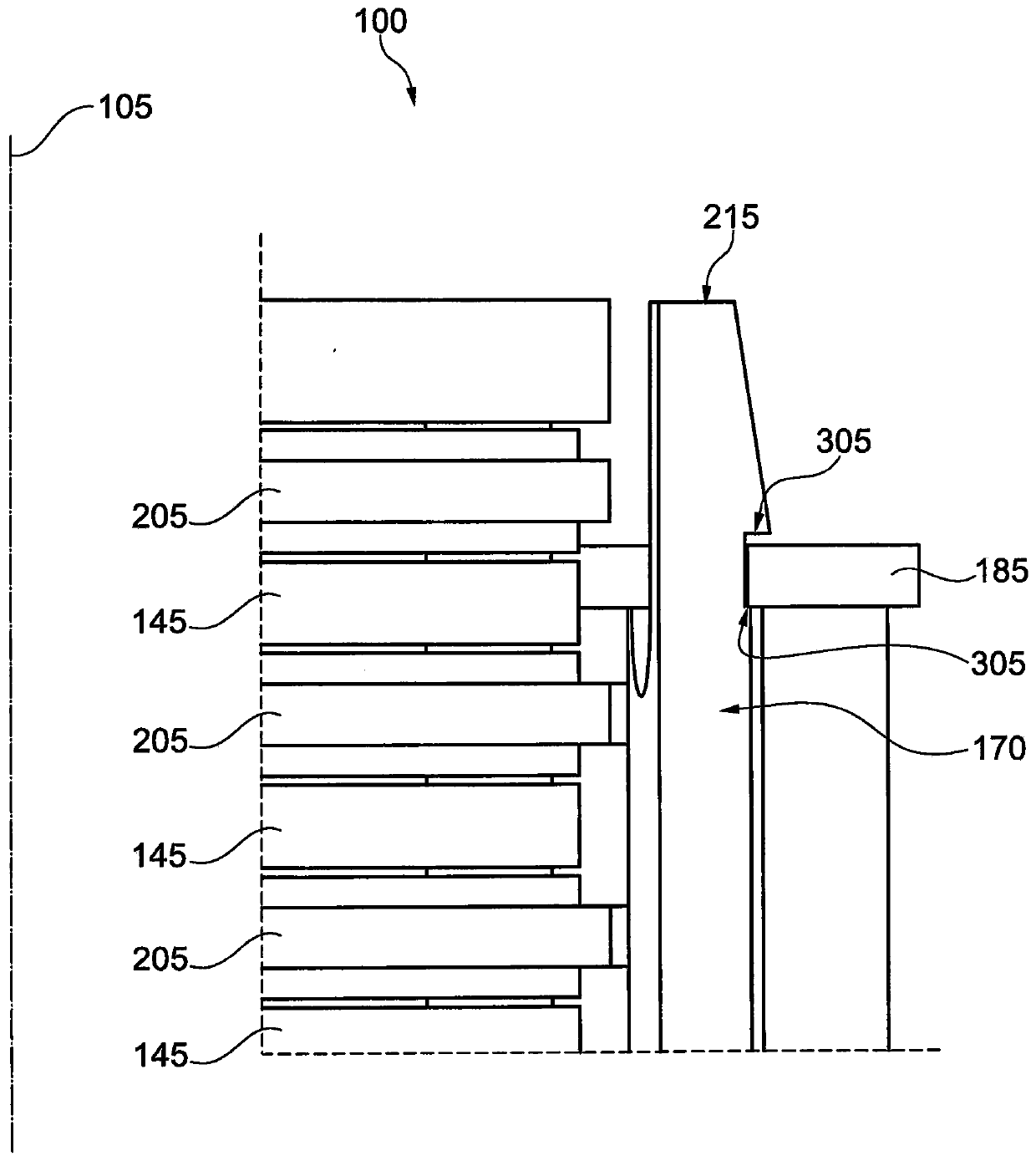

[0023] figure 1 A multi-plate clutch 100 for use in motorcycles, in particular scooters, is shown. The motorcycle can have a piston reciprocating internal combustion engine with one or more cylinders, and any cylinder of the internal combustion engine can be approximately 170-250 cm 3 , for example about 200cm 3 .

[0024] The multi-disc clutch 100 includes an axis of rotation 105 about which an input side 110 and an output side 115 are rotatably arranged. In the embodiment shown, the output side 115 is located radially on the inside and the input side 110 is located radially on the outside, but the reverse arrangement is also possible. In the embodiment shown, a ring gear 120 is mounted on the input side 110 , in which ring generally a primary gear meshes, said primary gear being fastened directly on the crankshaft driving the engine.

[0025] The multi-disk clutch 100 includes an outer carrier 130 , which is connected here to the input side 110 , and an inner carrier 135...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com