Large area penetrating goaf bag-type filling treating method by areas and by steps

A pocket-type, large-area technology in the open area, applied in the fields of backfill, earthwork drilling, mining equipment, etc., can solve the problems of uncontrollable filling treatment process, poor treatment effect, and poor filling quality, etc., and improve the support capacity of ore pillars. , low cost, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

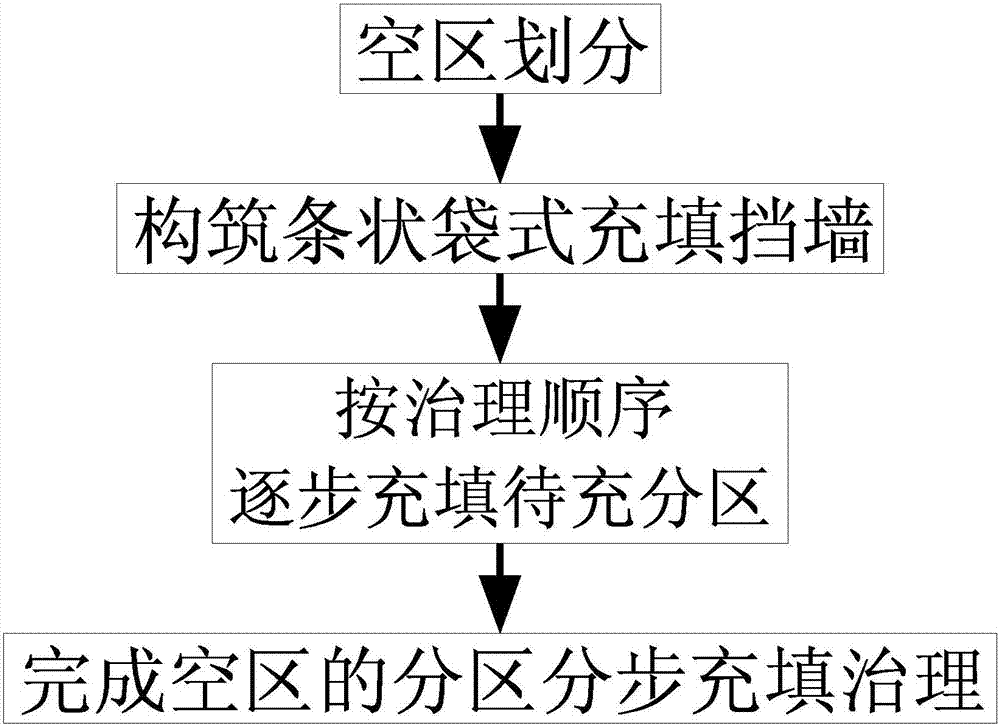

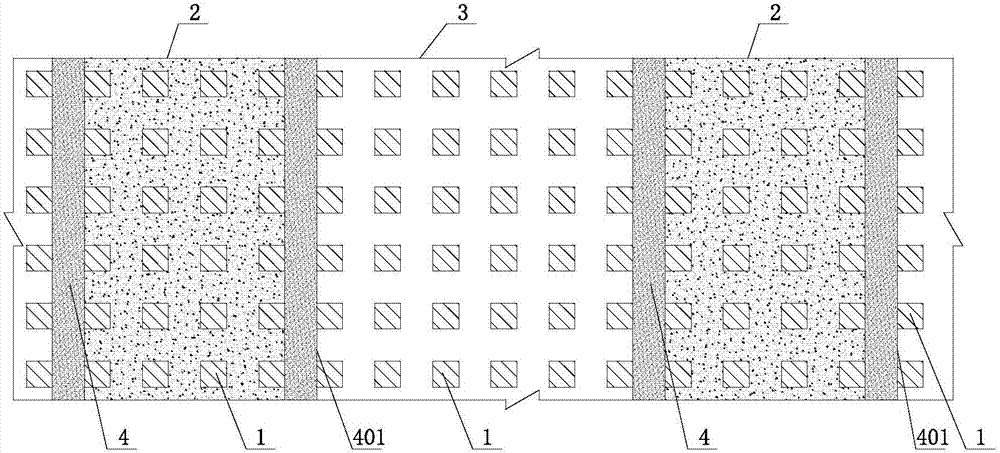

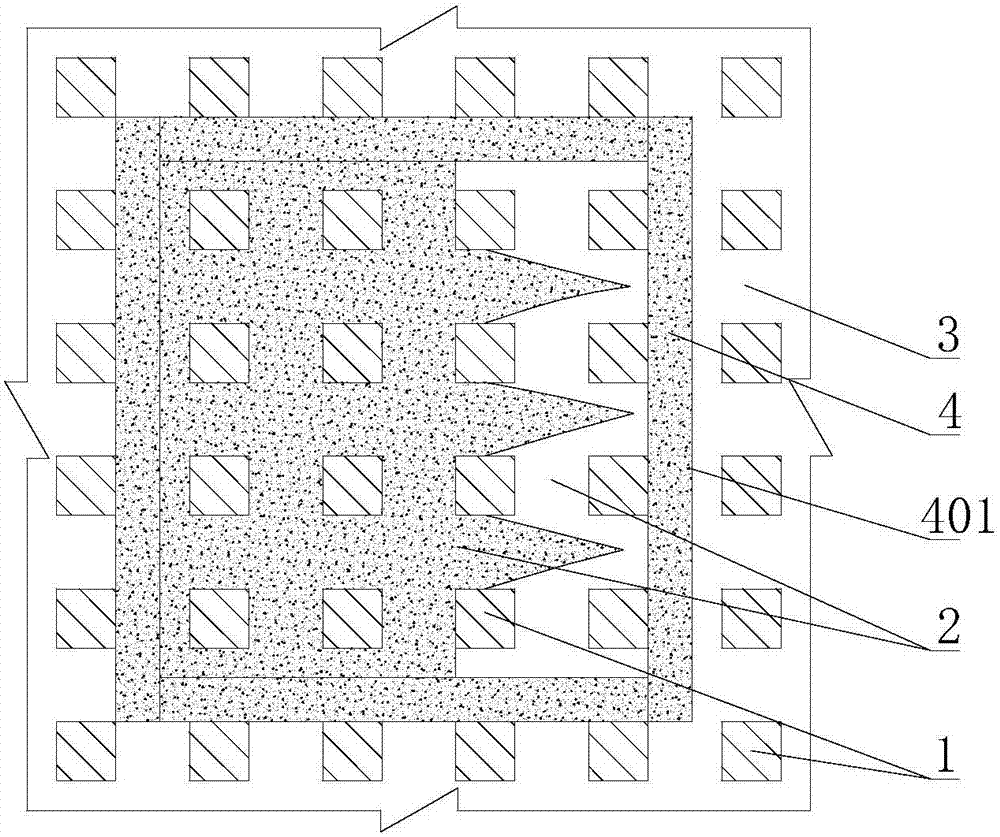

[0032] figure 1 It is a flow chart of the step-by-step filling management method of the large-area penetrating empty space bag-type partition in the preferred embodiment of the present invention; figure 2 It is a structural schematic diagram of the way of strip interval filling management in the preferred embodiment of the present invention; image 3 It is a schematic structural diagram of the partition filling management method in the preferred embodiment of the present invention.

[0033] like figure 1As shown, the large-area penetrating empty area bag-type partition step-by-step filling treatment method in this embodiment uses the bag-type filling enclosure technology to adopt partition step-by-step treatment or strip-interval filling treatment for empty are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com