Flush toilet lid

A toilet cover and flushing tube technology, applied in the field of toilet cover manufacturing, can solve the problems of complex structure and control of the flushing toilet cover, increase the manufacturing cost of the flushing toilet cover, unfavorable structural layout of the flushing toilet cover, etc. The effect of convenient structure layout, simplified structure and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

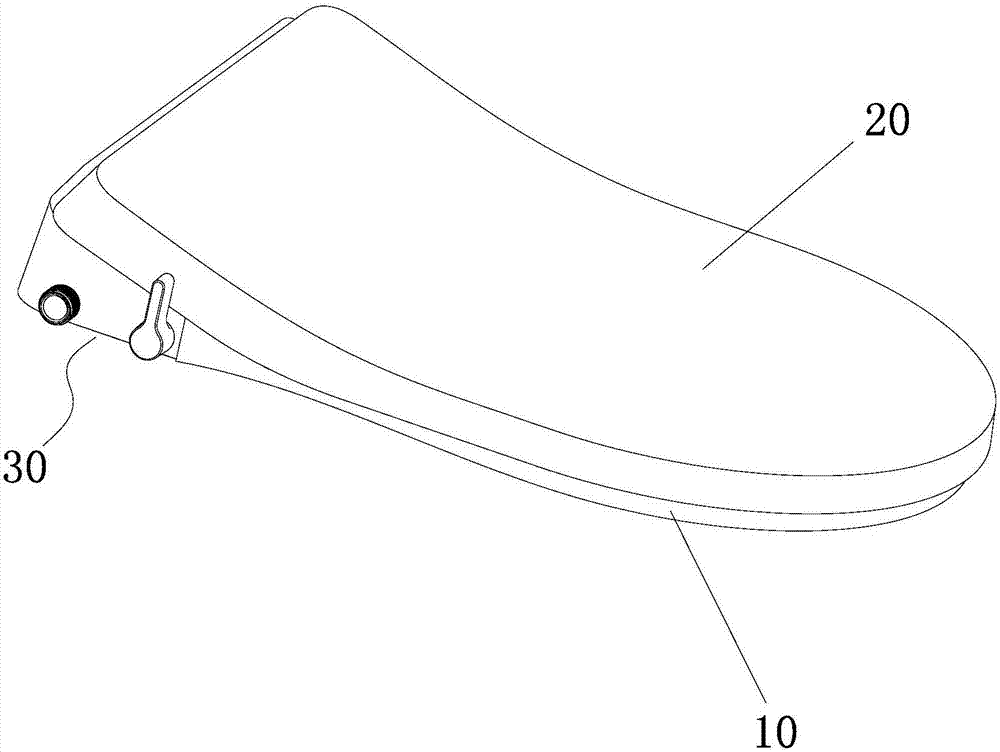

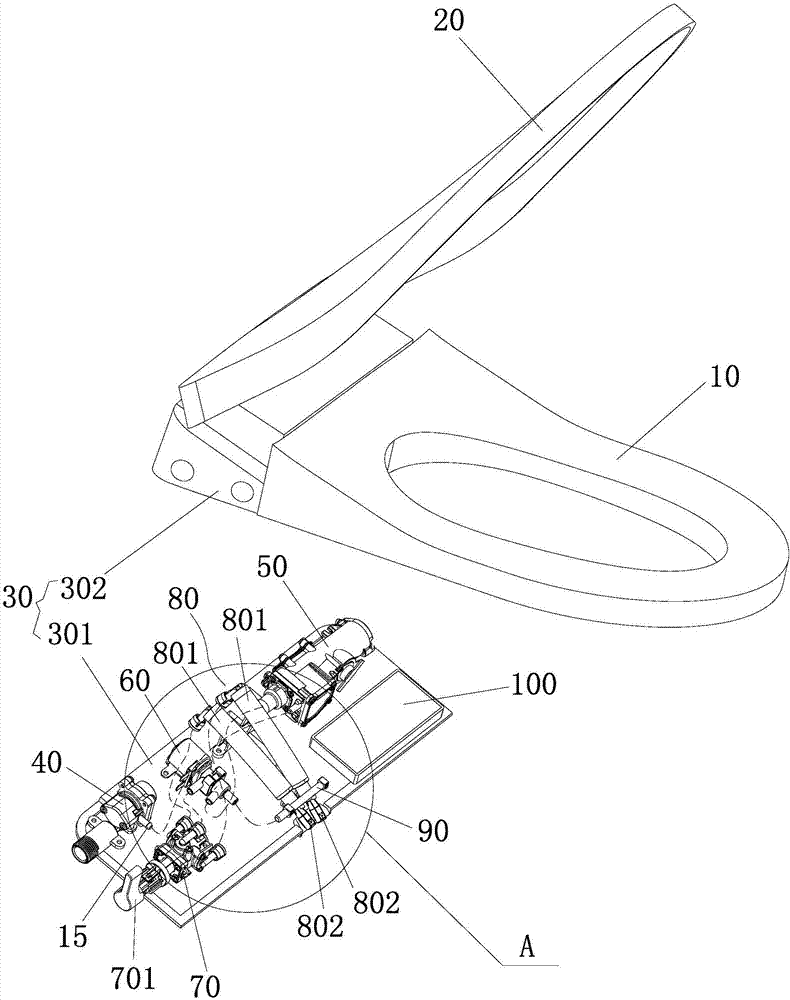

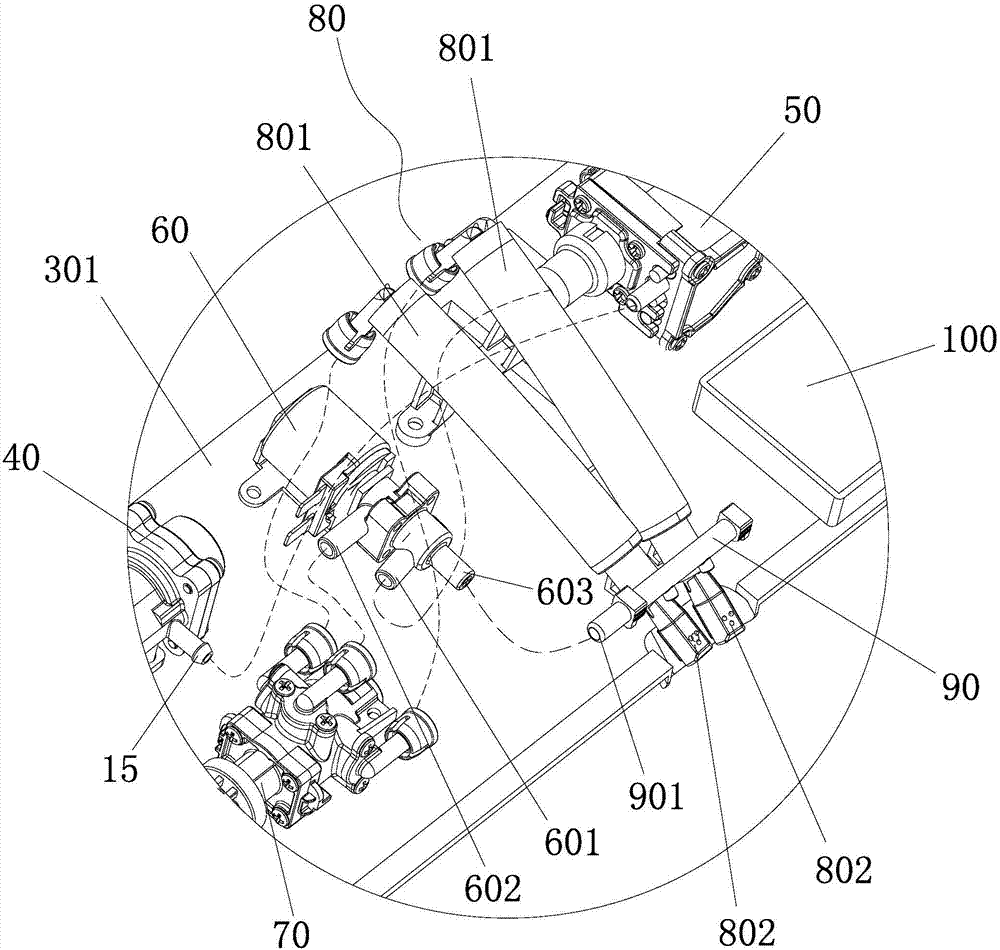

[0040] Figure 1 to Figure 19 As shown, a flush toilet cover includes a seat ring 10, a cover plate 20 and a housing 30, the rear parts of the seat ring 10 and the cover plate 20 are hinged on the housing 30, and the housing 30 includes a mounting base plate 301 and a cover The shell 302, the rear part of the seat ring 10 and the cover plate 20 are specifically hinged with the casing 302 on the casing 30, and the casing 302 and the installation bottom plate 301 are fastened with screws or clamped together; during installation, The installation base plate 301 is fixedly connected on the ceramic toilet.

[0041] The mounting bottom plate 301 of the housing 30 is equipped with a pressure reducing and steady flow valve 40, a heating assembly 50, an electromagnetic reversing valve 60, an on-off valve 70, a flushing assembly 80, a self-cle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap