Floating car seat headrest rod multi-dimensional oiling equipment

A technology for car seats and headrest rods, applied in the directions of coatings, devices for coating liquids on surfaces, etc., can solve the problems of contamination of headrests, changes, large manual labor, etc., and achieve the effect of uniform grease application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the embodiments and accompanying drawings.

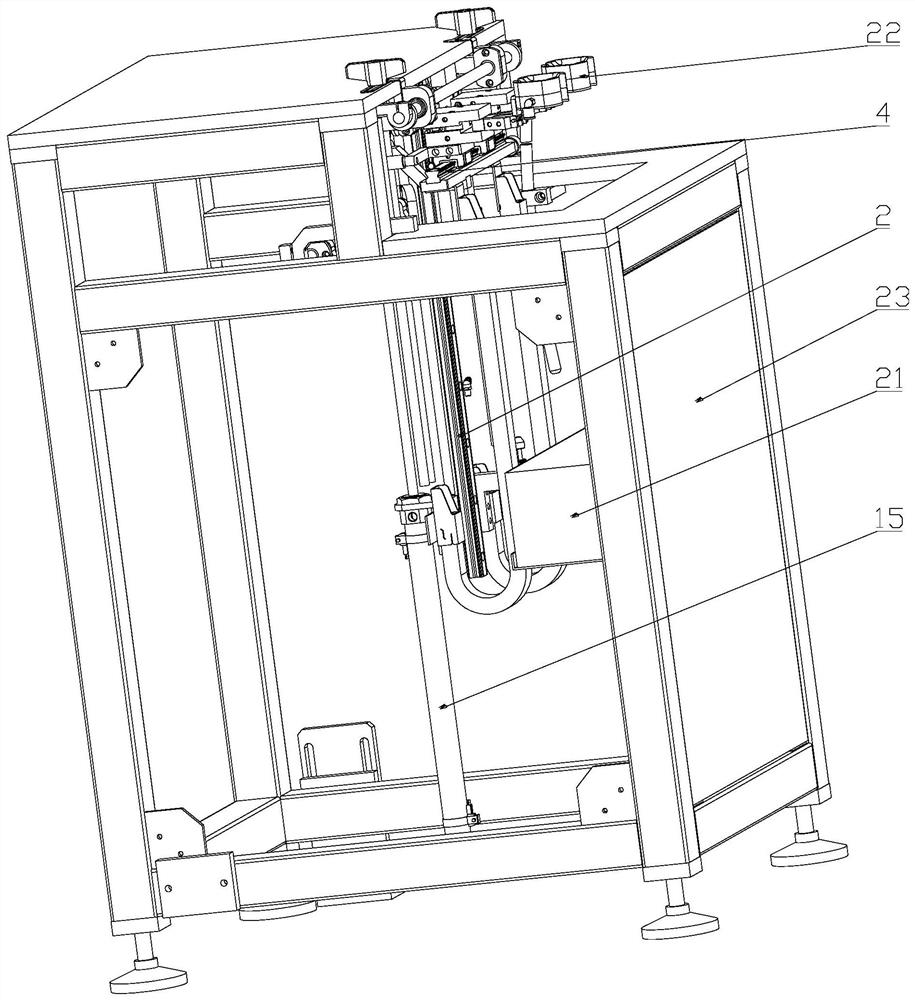

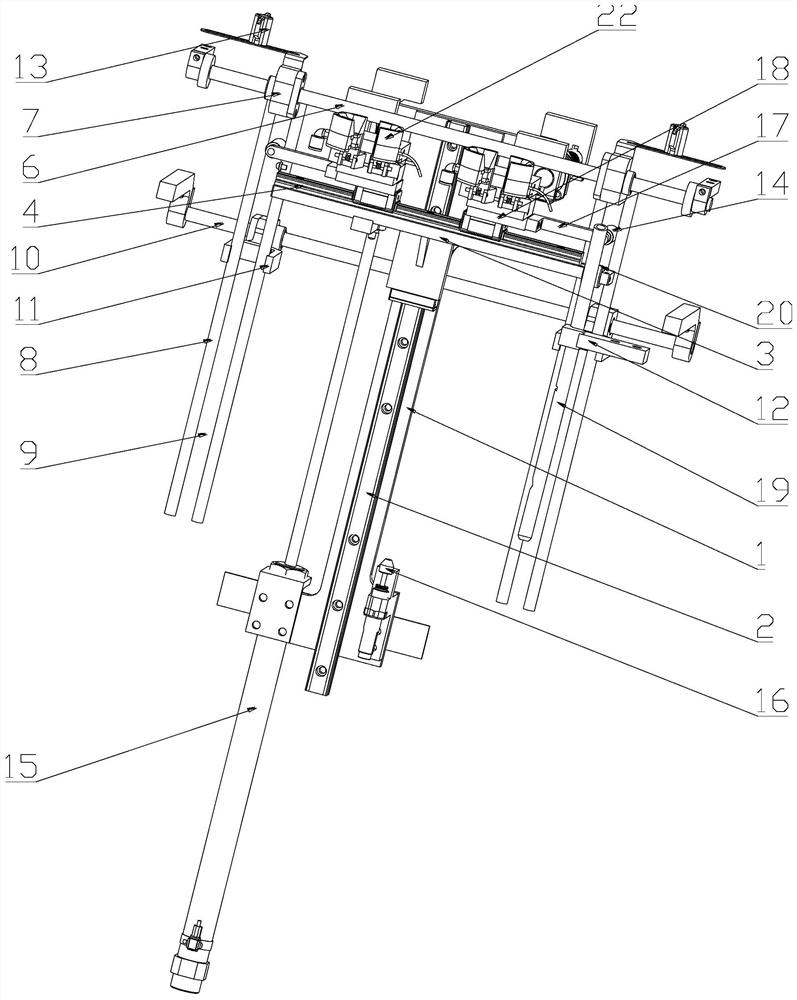

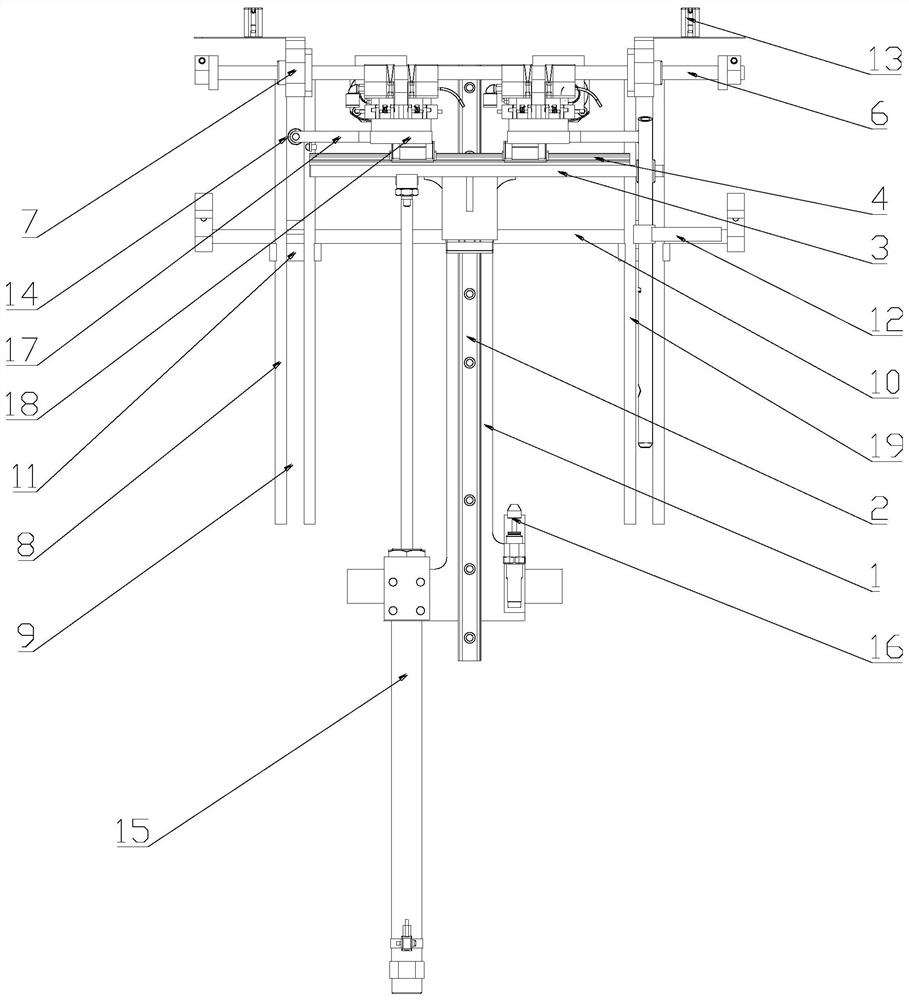

[0035] like Figure 1-2 As shown, a floating type car seat headrest rod multi-dimensional oiling equipment includes a chassis 23, and an oiling device 22 is arranged in the chassis 23, and the oiling device 22 is connected with a multi-dimensional moving mechanism;

[0036] The oiling device 22 includes a floating mechanism, the floating mechanism is provided with an oiling seat, the oiling seat is provided with an oiling through hole 2202, and the oiling through hole 2202 is provided with an upper sealing gasket and a lower sealing Gasket, the inner diameter of the upper sealing gasket and the lower sealing gasket is smaller than the diameter of the oiling through hole 2202, the oiling through hole 2202 between the upper sealing gasket and the lower sealing gasket forms an oil filling space, the oil filling space An oil filling pipe 2205 and an oil outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com