Polymer flooding oilfield overall process polymer injection parameter grading optimization decision method

A decision-making method and polymer technology, applied in design optimization/simulation, climate change adaptation, data processing applications, etc., can solve problems such as irrationality, failure to achieve fine polymer injection, and failure to fully consider the degree of injection, so as to achieve operational Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Take the stage-by-stage optimization decision-making method of polymer injection parameters in the whole process of polymer flooding in Bohai S Oilfield as an example. The specific steps are:

[0045] (1) Analysis of the main controlling factors of the effective speed in the early stage of effect and the comprehensive coefficient of water content drop in the peak stage of effect. In this embodiment, the gray correlation analysis method is selected to determine the main controlling factor.

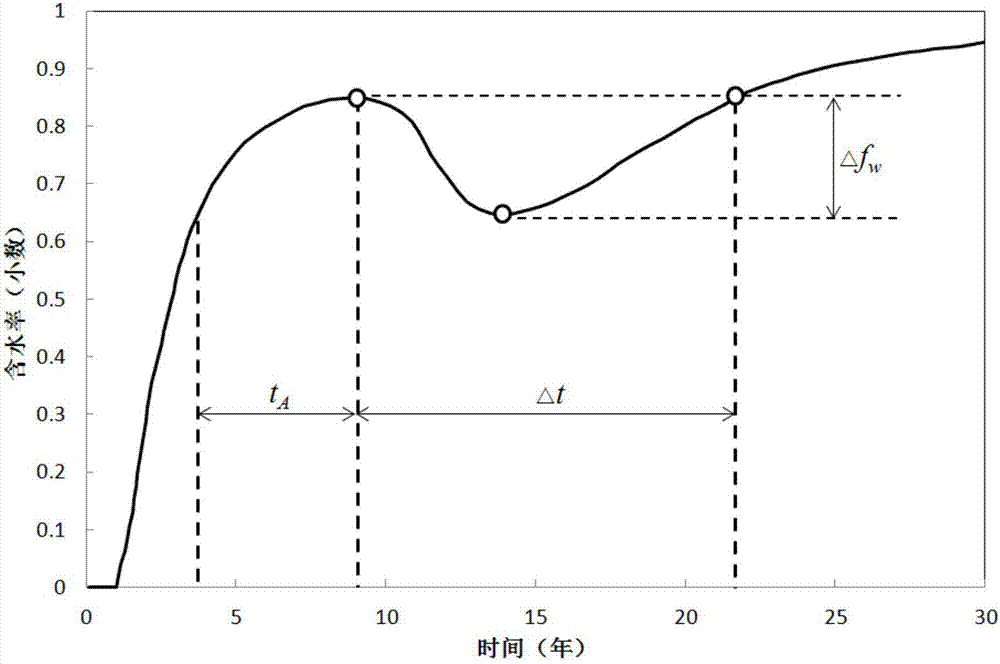

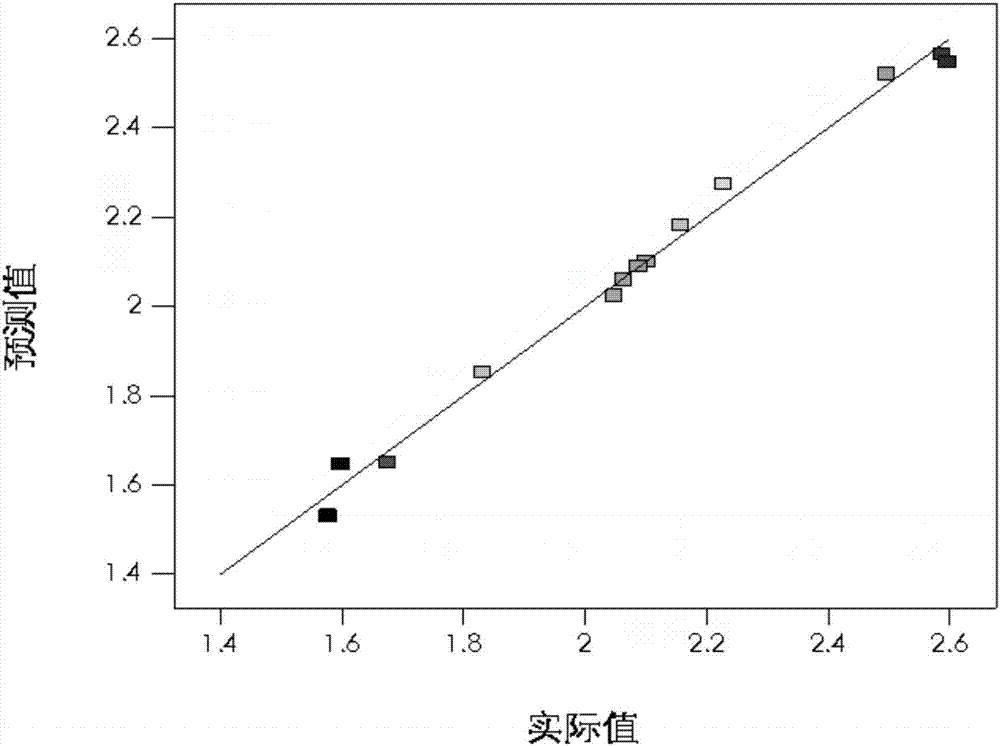

[0046] In the early stage of effective effect, the effective speed is selected as the reference sequence, and in the effective peak stage, the comprehensive coefficient of water cut decline is selected as the reference sequence. Timing, effective thickness of perforation, porosity, effect direction and number of small longitudinal perforation layers are used as comparison sequence, and the values of parameters of typical wells are calculated and statistically formed to form an anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com