Mixed integer programming-based metering device production plan optimization method

A technology of mixed integer programming and production planning, applied in computing, data processing applications, instruments, etc., can solve problems such as poor flexibility, reduction of central inventory and production costs, high inventory, etc., to achieve efficient execution, reduction of central inventory and production costs, Circumvention of artificial experience effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

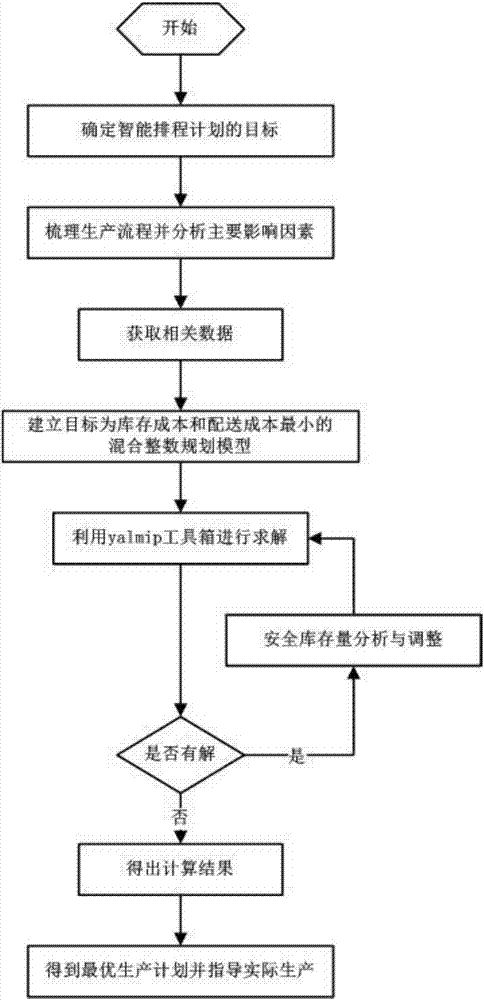

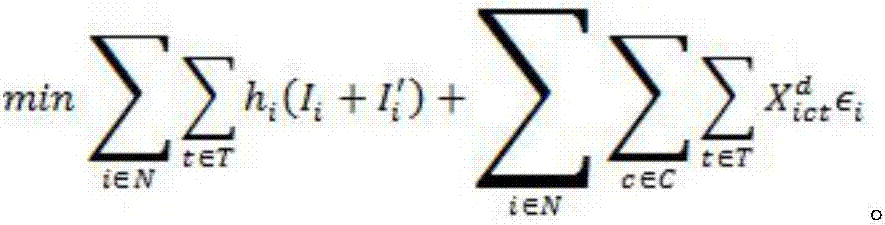

[0027] A production plan optimization method for metering devices based on mixed integer programming,

[0028] In the embodiment of the present invention, this project is based on the Advanced Scheduling Theory (APS), based on demand forecasting and measuring instrument detection status and constraints, and adopts the operation research optimization method to realize the intelligent scheduling of the entire process, so as to meet the requirements of downstream stations ( Secondary sub-warehouse and direct distribution warehouse), while ensuring that the inventory turnover rate of finished products meets the rated value set by the enterprise, and reducing the overtime hours of workers on the inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com