A Fast Multivariable Predictive Control Method for Ethylene Cracking Furnace

An ethylene cracking furnace, predictive control technology, applied in general control systems, control/regulation systems, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

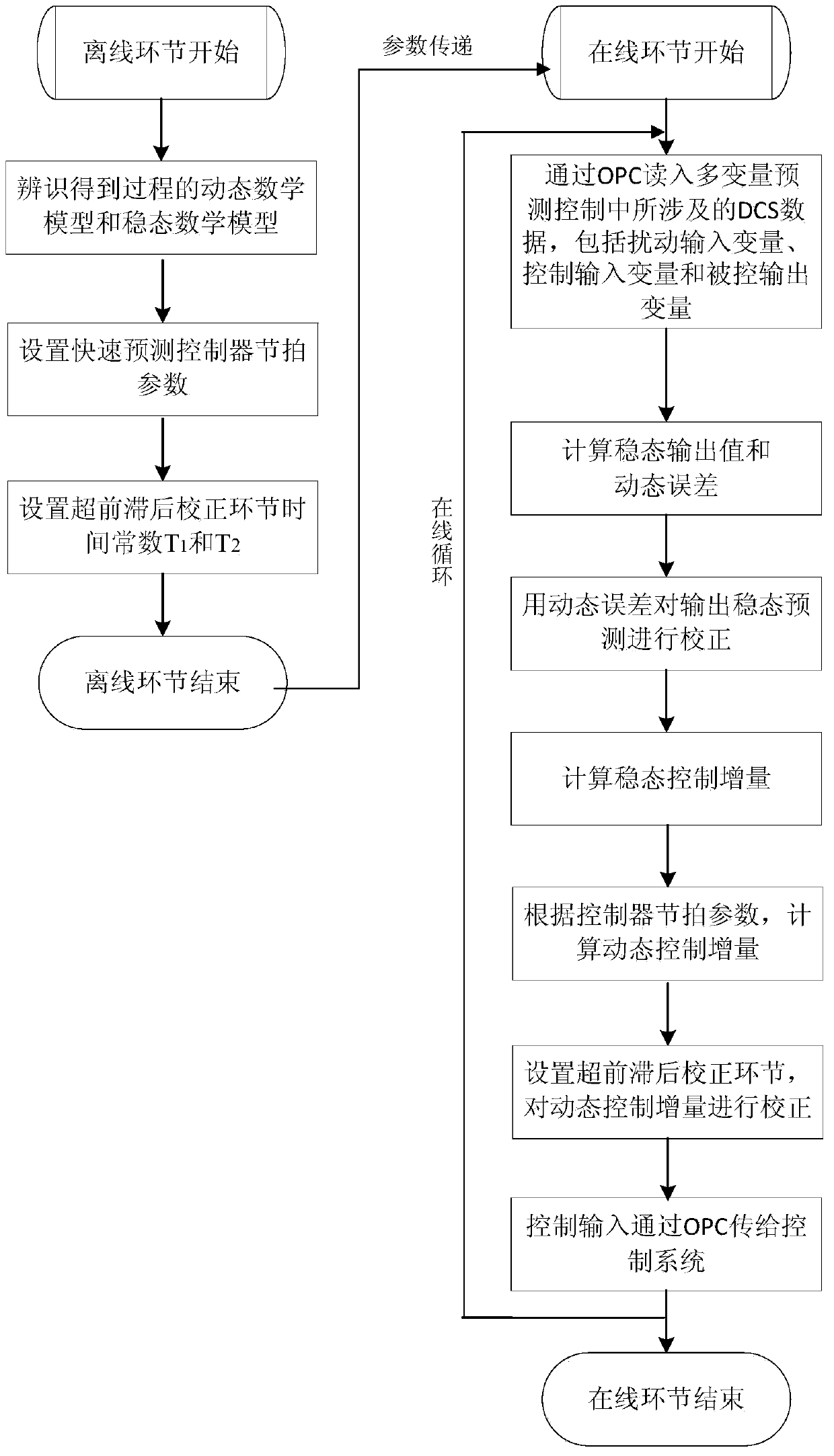

[0071] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

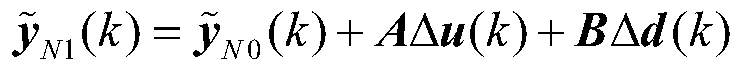

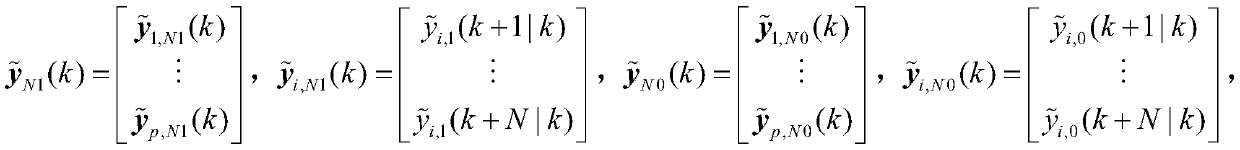

[0072] The present invention has offline and online links. In the off-line link, the dynamic mathematical model and the steady-state mathematical model of the ethylene cracking furnace production process are obtained through analysis or identification methods, and control parameters are set. In the online link, the output prediction value is first calculated according to the measured value of the ethylene cracking furnace control system (DCS), and the prediction error is calculated according to the difference between the predicted value and the measured value to correct the steady-state output prediction value; then, through steady-state optimization or direct inversion The method calculates the predictive value of the steady-state control input; finally calculates the control input value at the current moment according to the given control pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com