The Control Method of Yield Estimation in Caustic Soda Automated Production

A control method and output technology, which are applied in the control field of reverse estimation of output in the production process of flake soda, can solve the problems of increasing workload and work intensity, affecting product quality, and being difficult to achieve production conditions, and improving detection accuracy. and control accuracy, reduce the labor intensity of workers, and eliminate the effect of accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

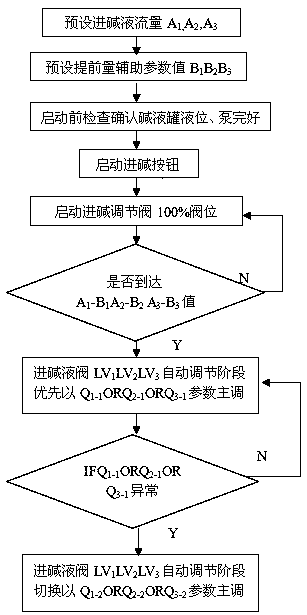

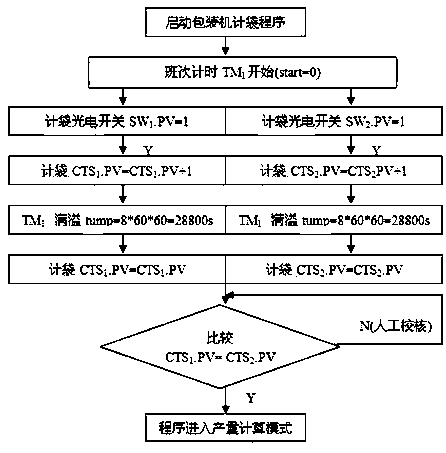

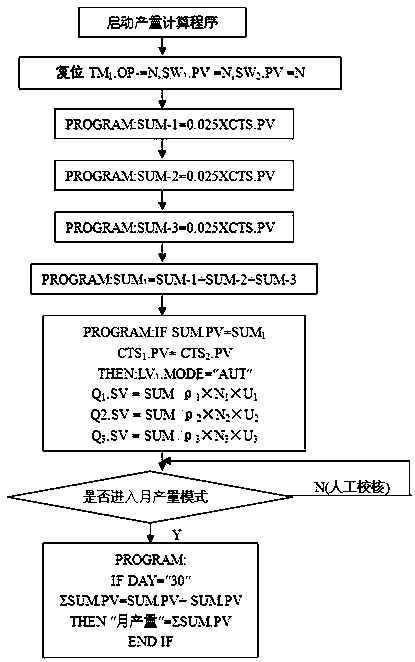

[0029] Refer to attached figure 1 -3, Embodiment 1 of the present invention is that the DCS control system controls the whole process of feeding→reacting→discharging the lye of the concentrator. Among them, 1# pre-concentrator, 2# pre-concentrator, and the final concentrator add a new heat exchanger and an anti-interference flowmeter to the lye inlet pipeline before the three concentrators, and add a new heat exchanger and an anti-interference flowmeter to enter the lye in the lye stage. The liquid flow, liquid level and temperature in the concentrator are used as the main adjustment parameters; a new check bag photoelectric switch is added during the packaging process, and its closing times are the main parameters; the hardware includes on-site control station, operation station, engineer station, communication network cable ; The software includes the operating system platform and DCS configuration software for industrial control. This technology is directly applied to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com