Four-axis alignment adjustment system and method for biaxial tensile testing machine

A technology of centering adjustment and biaxial stretching, which is applied in the field of testing machines, can solve the problems of disassembly and real-time adjustment, and achieve the effect of increasing the clamping area, high reliability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The details of the present invention and specific implementations thereof will be further described below with reference to the accompanying drawings.

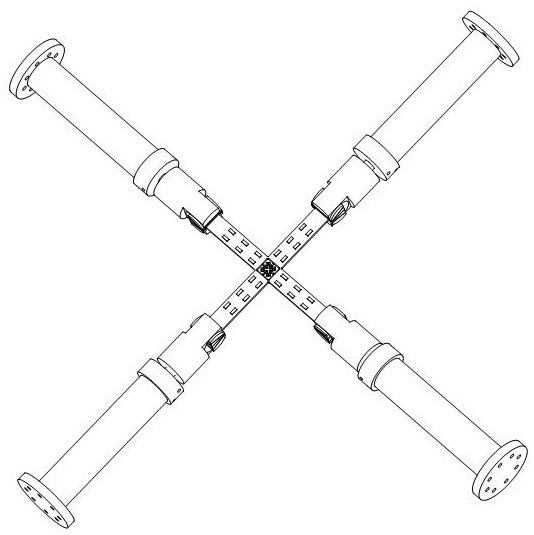

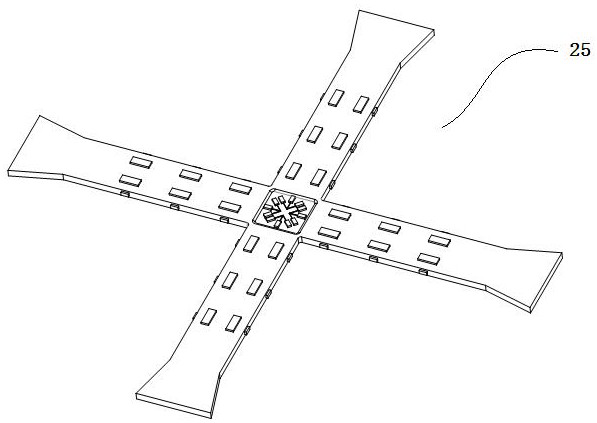

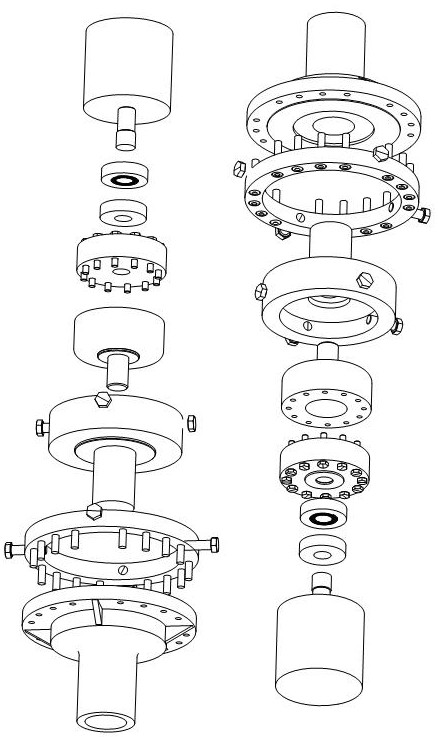

[0079] see Figure 1 to Figure 14As shown, the four-axis centering adjustment system and method for a biaxial tensile testing machine of the present invention solves the problem that the coaxiality of the loading chain of the existing biaxial testing machine needs to be disassembled and the loading chain cannot be adjusted in real time. To a certain extent, it fills the gap of the existing technology; the adjustment amount reaches 0.01mm / grid, and the adjustment range is ±0.5mm, ±0.35°; the biaxial alignment sensor can identify the five freedoms such as the coaxial, angle, and torsion of the loading chain At the same time, the verticality of the two axes in the orthogonal direction and the flatness of the axes can be analyzed, and the detection accuracy is 0.01mm; the coarse adjustment device can be used to limit the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com