Method and system for monitoring leakage of heat supply pipeline

A heating pipeline and monitoring system technology, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of distortion of results, high cost of heating pipelines, and high waterproof performance requirements Advanced problems, to achieve the effect of small environmental factors and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

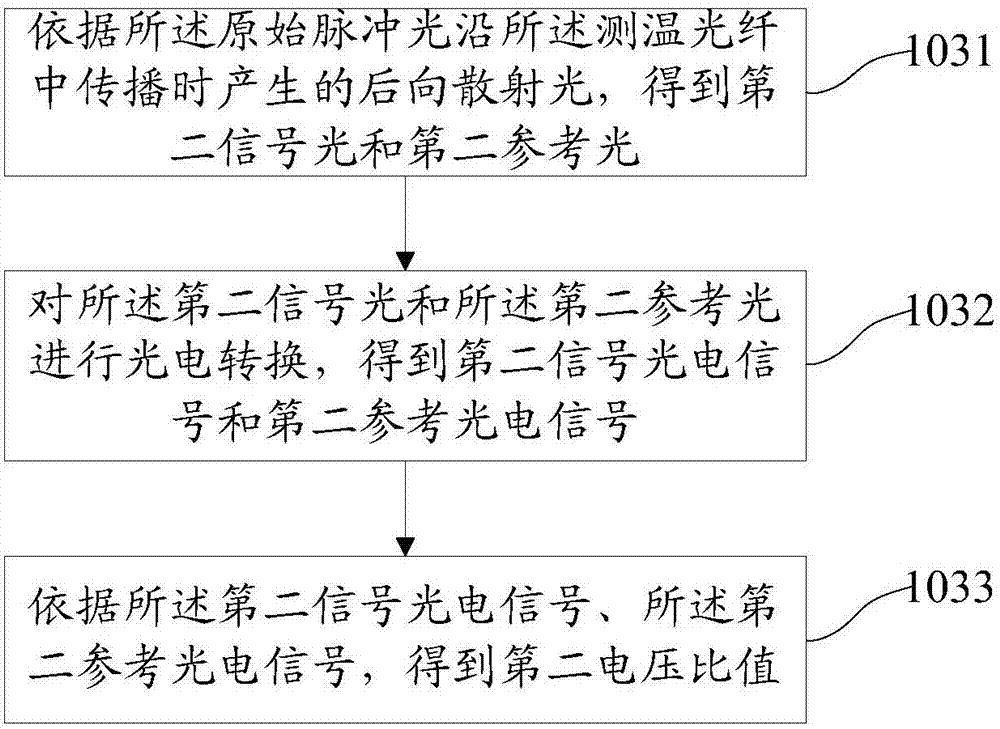

[0059] One of the core concepts of the embodiments of the present invention is to emit the original pulsed light through the light source; according to the scattered light generated when the original pulsed light propagates along the calibration fiber, the ratio between the first temperature value and the first voltage ratio of the calibration fiber is obtained Correspondence among them; according to the scattered light generated when the original pulsed light propagates along the temperature-measuring fiber, the second voltage ratio of the temperature-measuring fiber is obtained; according to the second voltage ratio, and the first temperature and the first temperature A corresponding relationship between voltage ratios to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com