A method for plugging off layer water supply source

A layer-separation and replenishment technology, applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problems of large grouting drilling engineering volume and increased grouting, so as to improve the grouting efficiency, reduce the cost, and eliminate the threat of water damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

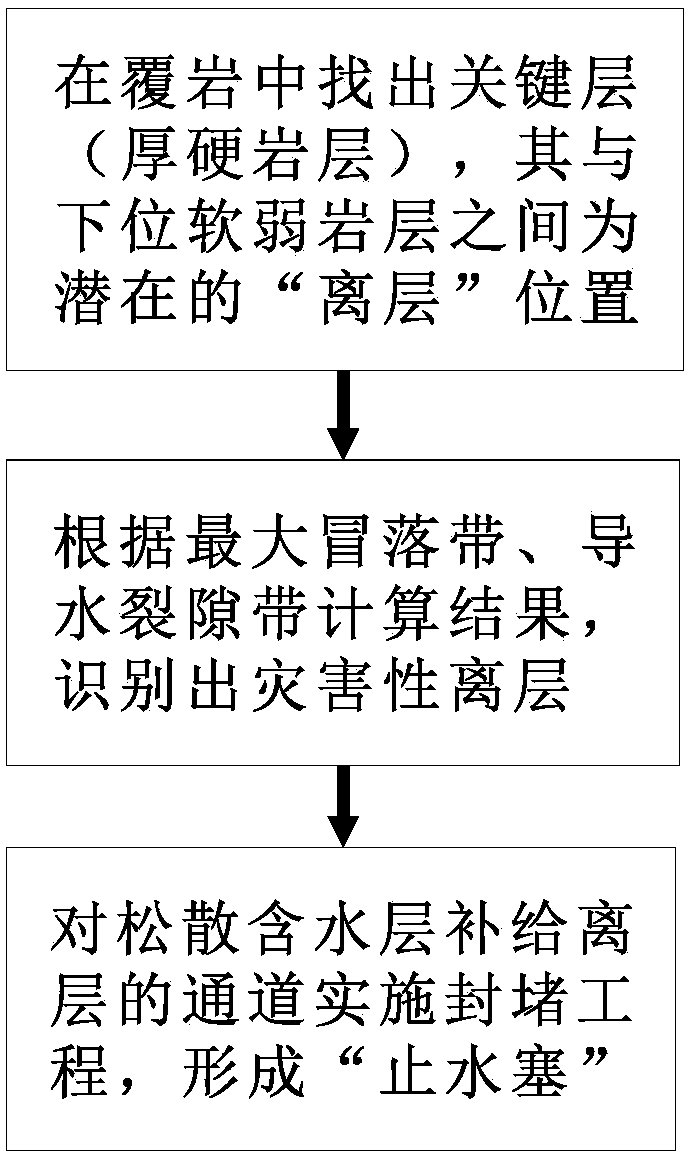

[0039] Such as figure 1 Shown, a kind of plugging method of absorptive water replenishment source is suitable for inclined rock coal seam; comprises the following steps:

[0040] Step 1. Locate all abscissions in the overburden

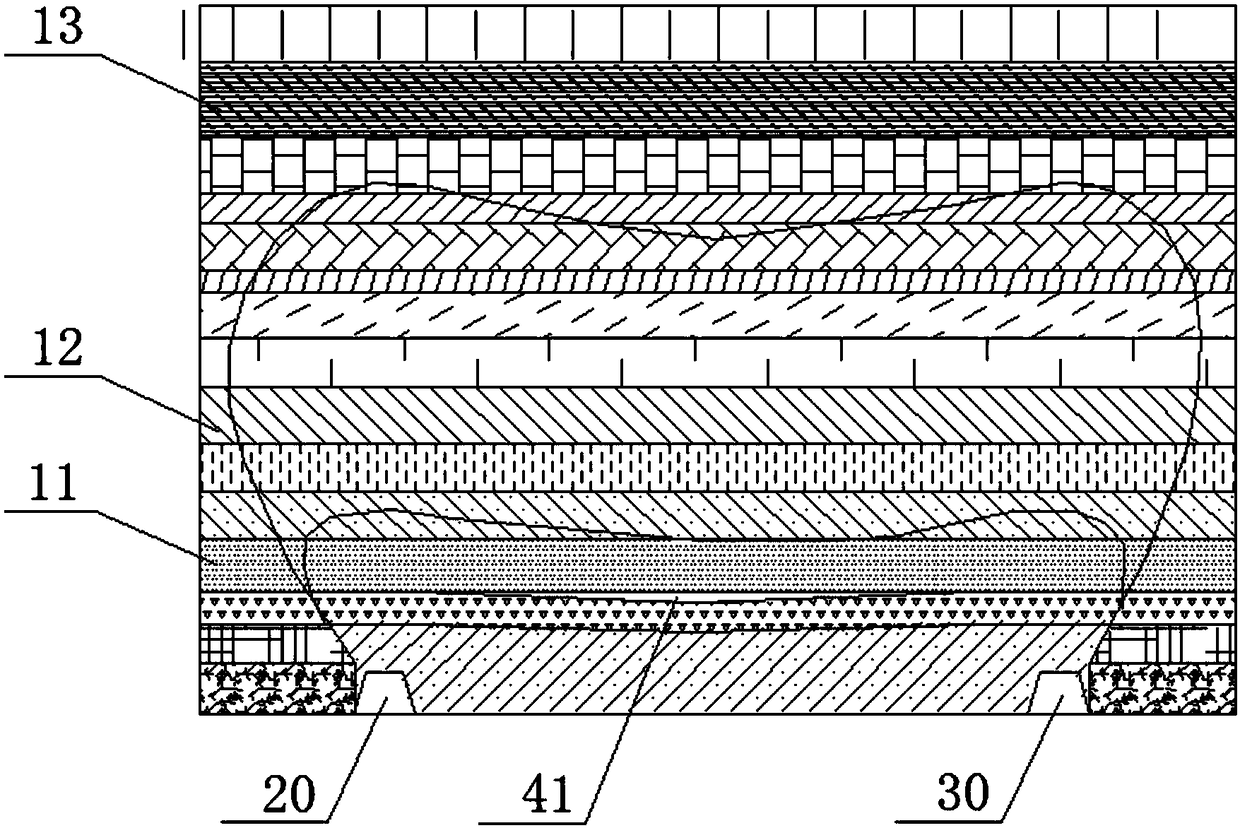

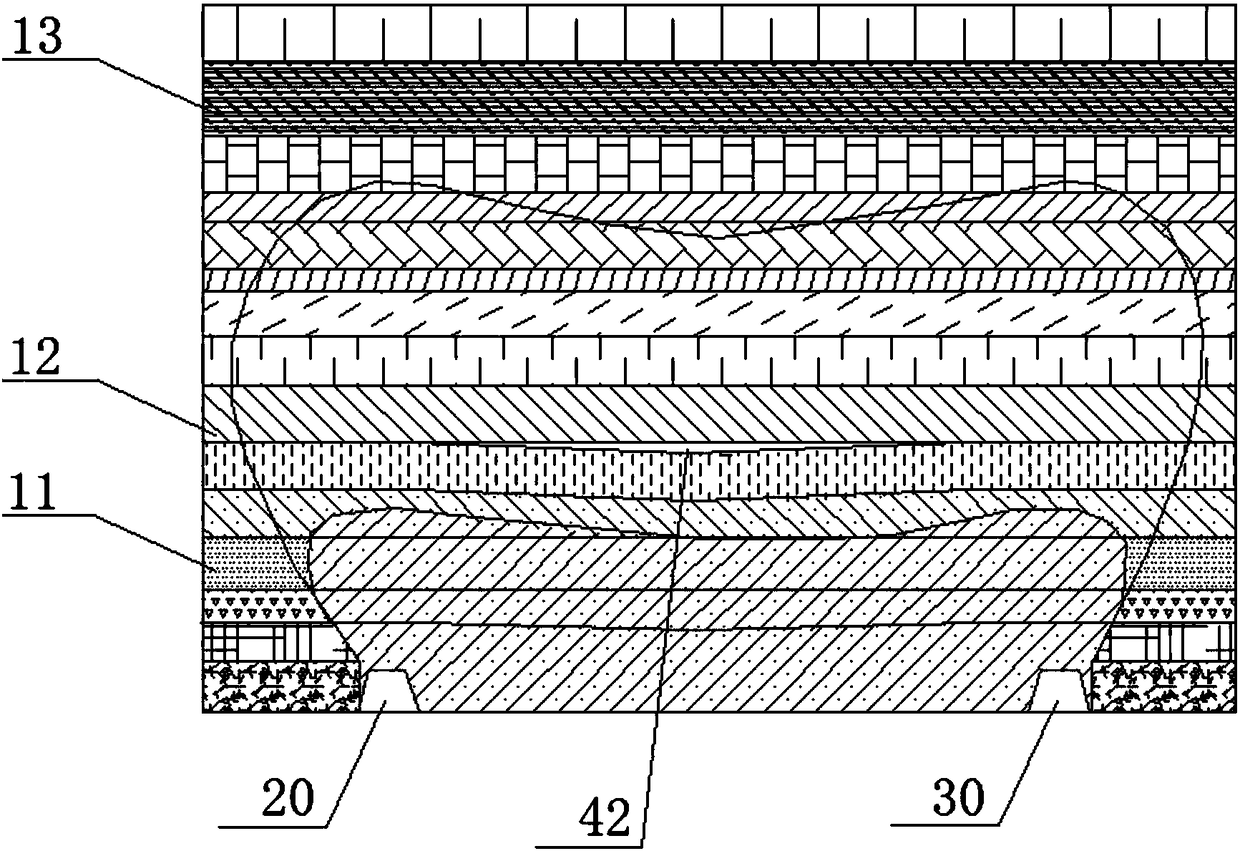

[0041] Such as Figure 2 to Figure 4 As shown, the coal-measure strata are composed of soft and hard rock layers with different physical and mechanical properties. Generally, this kind of thick and hard rock layer plays a key control role in the movement of rock layers caused by coal mining, so it is called the key layer in the literature. The location of potential abscission space is between the key layer and the weak rock layer below it. In the overlying rock, there may be many combinations of such key layers and weak rock layers, so there are also multiple potential abscission spaces, which need to be determined one by one. Judging the first key layer 11, the second key layer 12, the third key layer 13, etc. according to the lithology and thic...

Embodiment 2

[0058] The following takes two grouting hole groups as examples to describe in detail:

[0059] Such as Figure 5 , Image 6 , Figure 7 As shown, the working face is determined by the machine lane 20, the wind lane 30, the cut eye (starting point of recovery) and the closing end (end point after recovery), and its length is L and the width of the slope is S. First determine the disastrous detachment layer 43 according to the method provided in embodiment 1, and the detachment water supply line above the wind tunnel, then design "one station porous group" (a grouting station 50 and a plurality of grouting holes) according to the site conditions Group abbreviation) grouting scheme. Specifically:

[0060] (1) The grouting station 50 is built in the middle of the two grouting hole groups, and its function is to prepare the grout according to the engineering requirements of preventing and controlling the water damage of the separation layer 43, and transport the grout through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com