A shield grouting material for severe environment

A grouting material and environmental technology, applied in the field of building materials, can solve problems such as impermeability and corrosion resistance of grouting materials, reinforced concrete structure infringement, etc., to avoid low consolidation shrinkage, improve fluidity, High water reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

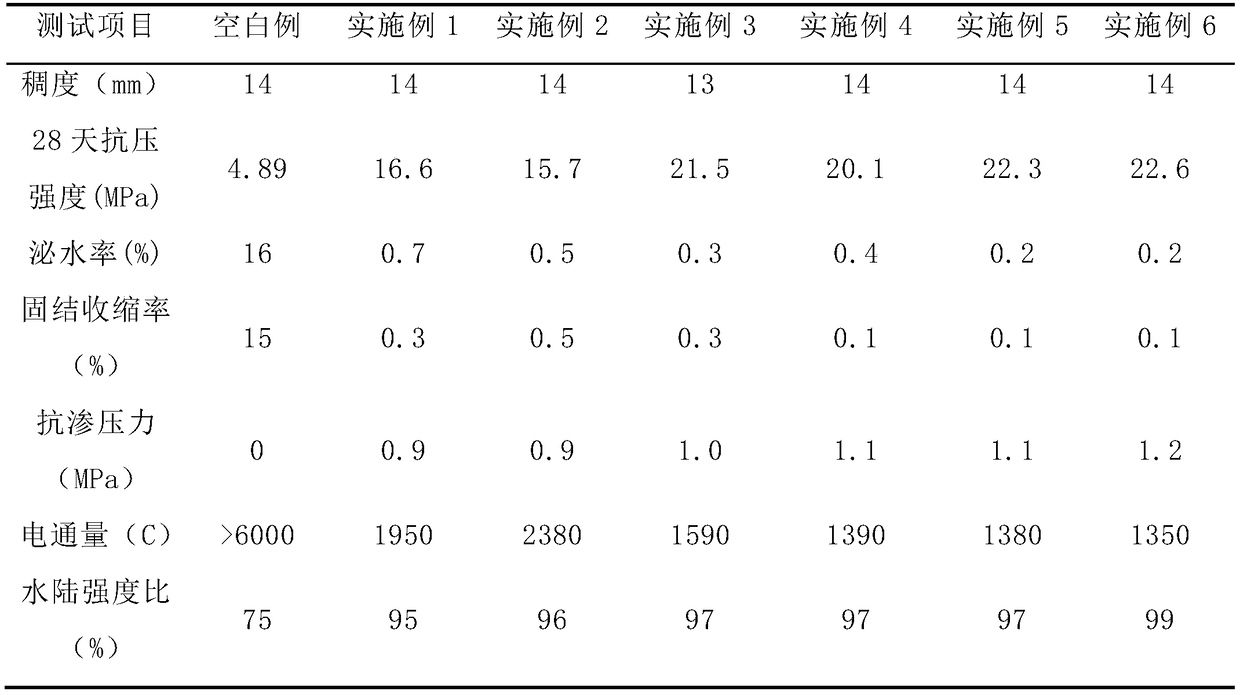

Examples

Embodiment 1

[0048] Burn 1235g of river sand, 600g of P.O42.5 ordinary Portland cement, 547g of secondary fly ash, 67g of silica fume (CABR-SF101 sold by China Academy of Building Research), and 383g of functional superfine powder Body material (CABR-SP206 sold by China Academy of Building Research), 16g water-resistant dispersant (polyurethane water-resistant dispersant CABR-RA106 sold by China Academy of Building Research), 88g composite expansion agent (Jianyan Kunlun Technology Co., Ltd. Sales of plastic expansion agent and calcium oxide and magnesium sulfoaluminate composite expansion agent KL-E105), 53g of anti-corrosion rust inhibitor (Nitrite CABR-AP02 sold by China Academy of Building Research), 11g of high-performance water reducer (China The CABR-J1 sold by the Institute of Building Research) was put into a mortar mixer and stirred for 120 seconds to make the materials evenly mixed. Then add the water of 877g and stir for 120 seconds again, make finished material L 1 .

Embodiment 2

[0050] 1500g of river sand, 750g of P.O42.5 ordinary Portland cement, 270g of secondary fly ash, 120g of silica fume (CABR-SF101 sold by China Academy of Building Research), 150g of functional superfine powder Body material (CABR-SP206 sold by China Academy of Building Research), 54g water-resistant dispersant (polyurethane water-resistant dispersant CABR-RA106 sold by China Academy of Building Research), 45g composite expansion agent (Jianyan Kunlun Technology Co., Ltd. Sales of plastic expansion agent and calcium oxide and magnesium sulfoaluminate composite expansion agent KL-E105), 90g anti-corrosion and rust inhibitor (borate inorganic anti-corrosion and rust inhibitor CABR-AP07 sold by China Academy of Building Research), 21g high-performance Put the water reducer (CABR-J1 sold by China Academy of Building Research) into the mortar mixer and stir for 120 seconds to make the materials evenly mixed. Then add the water of 750g and stir for 120 seconds again, make finished ma...

Embodiment 3

[0052] 1235g of river sand, 705g of P.O42.5 ordinary Portland cement, 300g of secondary fly ash, 125g of silica fume (CABR-SF101 sold by China Academy of Building Research), 370g of functional superfine powder Body material (CABR-SP206 sold by China Academy of Building Research), 55g water-resistant dispersant (methylolacrylamide water-resistant dispersant CABR-RA201 sold by China Academy of Building Research), 88g composite expansion agent (Building Research Calcium oxide-calcium sulfoaluminate composite expansion agent KL-E203) sold by Kunlun Technology Co., Ltd., 105g anti-corrosion and rust inhibitor (CABR-AP09 of nitrite organic-inorganic composite anti-corrosion and rust inhibitor sold by China Academy of Building Research), Put 18g of high-performance water reducer (CABR-J1 sold by China Academy of Building Research) into the mortar mixer and stir for 120 seconds to make the materials evenly mixed. Then add the water of 780g and stir for 120 seconds again, make finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com