The water purifier under the base of the water purifier with double-layer plug-in base is installed

A technology of plug-in base and water-passing device, which is applied in water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Popularity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

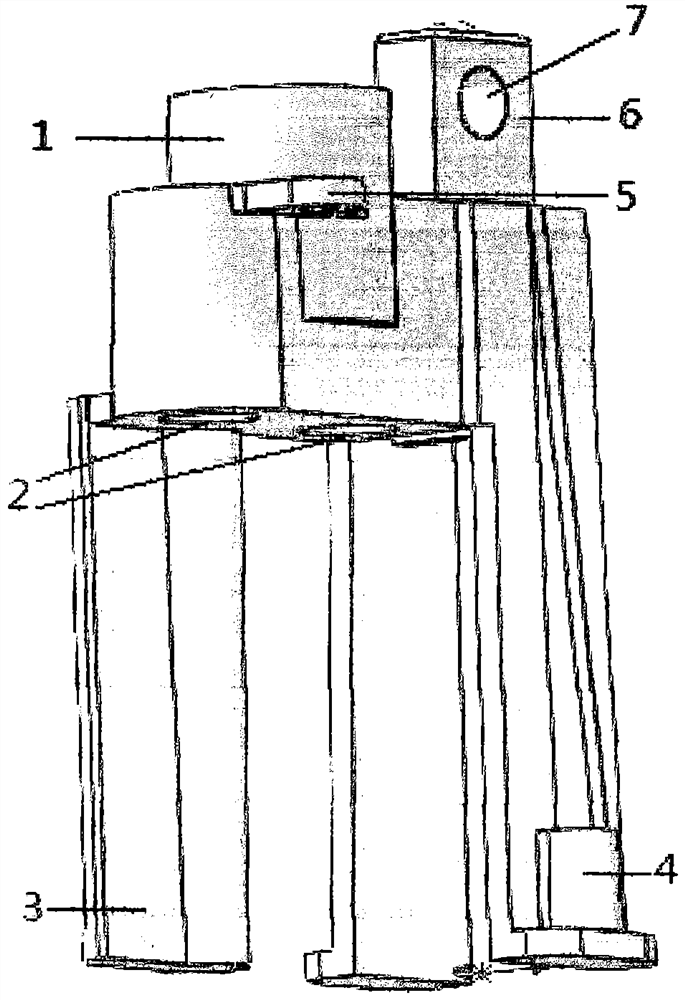

[0020] Example 1. The lower end of the upper machine base of the machine is provided with a lower water inlet and is connected to the concentrated water outlet of the fine filter gallbladder. The upper water inlet with the fastening structure, the concave hole structure on the side wall, and the water stop valve are all placed on the lower machine base of the machine. The upper water outlet is fixed on the lower machine base through a fastening structure; the connection between the water stop valve and the lower part of the upper water outlet is fixed, the water inlet is connected to the upper water outlet, and the water outlet is connected to the thickening hose. The knob of the water stop valve stretches out the side wall concave hole structure of the lower floor support. The connection and matching positions of the upper and lower machine bases correspond to the matching positions where the upper and lower water inlets are inserted into each other and connected to the conc...

Embodiment 2

[0025]Example 2. The lower end of the upper machine base of the machine is provided with a lower water inlet and is connected to the concentrated water outlet of the fine filter gallbladder. The upper water inlet with fastening structure, the concave hole structure on the side wall, the water stop valve and the concentrated water discharge control device are all placed on the lower machine base of the machine. The upper water outlet is fixed on the lower machine base through a fastening structure; the concentrated water discharge control device and the lower part of the upper water outlet are connected and fixed to form an integral body. The water inlet end of the water stop valve is connected to the upper water inlet through the concentrated water discharge control device, and the water outlet end is connected to the concentrated discharge hose. The knob of the water stop valve protrudes from the side wall recessed hole structure on the machine base. The connection and matc...

Embodiment 3

[0029] Example 3. The lower end surface of the upper machine base of the machine is provided with a lower water inlet connected to the concentrated water outlet of the fine filter gallbladder, and a lower water tank connected to the concentrated water tank of the upper machine base. The upper water inlet of the fastening structure and the upper water inlet of the water tank, the side wall concave hole structure, the water stop valve and the concentrated water discharge control device are all placed on the lower machine base of the machine, wherein the upper water inlet of the water tank and the upper machine base Corresponding to the water outlet under the water tank.

[0030] The upper water inlet is interfitted with the lower water outlet connected to the concentrated water outlet of the fine filter gallbladder; the water inlet of the concentrated water discharge control device is connected with the upper water outlet, and the water outlet of the concentrated water control d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com