Self-leveling nuclear power station construction matched hoisting structure

An automatic leveling, nuclear power plant technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of easy bumping and difficulty in ensuring the balance of the main pipeline, and achieve the effect of improving the level and reducing the risk of collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

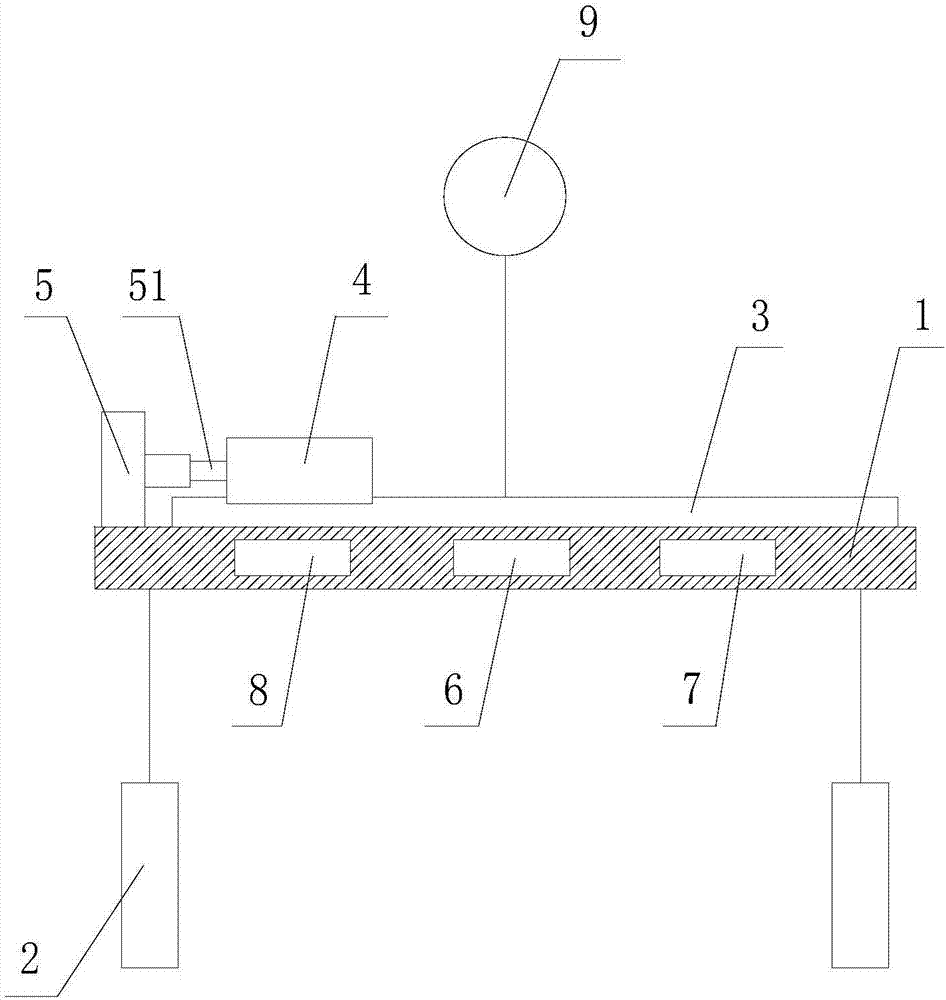

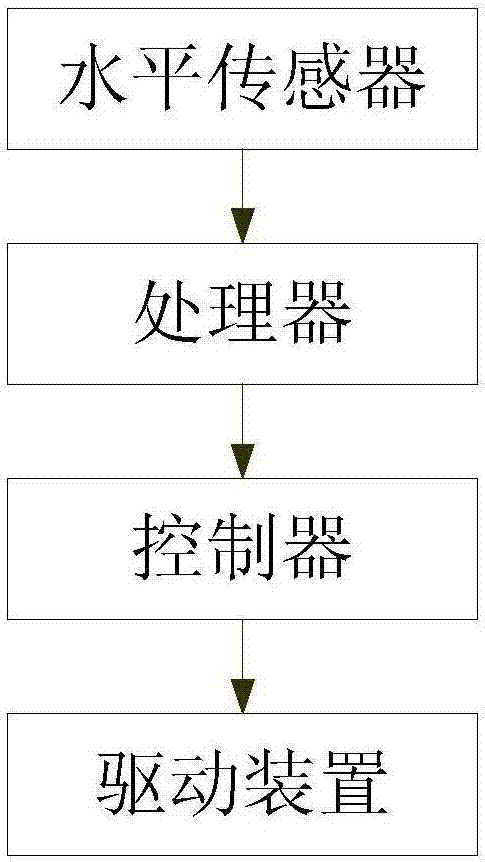

[0022] Such as figure 1 and figure 2 The self-leveling nuclear power plant construction supporting lifting structure shown includes a strip-shaped frame body 1, a hanging ring 9 is fixedly connected to the top of the frame body 1, and two pipe clamps 2 are fixedly connected to the bottom of the frame body 1; The upper surface is also provided with a slide rail 3 along the long axis direction of the frame body 1 and a slide block 4 that can move along the slide rail 3; one end of the slide rail 3 is fixed with a driving device 5, and the driving device 5 The driving direction is consistent with the length direction of the slide rail 3, and the driving end 51 of the driving device 5 is connected with the slider 4; it also includes a level sensor 6, a processor 7, and a controller 8 arranged on the frame body 1, and the level sensor 6 connected to the input of the processor 7 , the input of the controller 8 is connected to the output of the processor 7 , and the output of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com