Automatic feeding device for buffer blocks

A technology of automatic feeding and buffer block, applied in packaging and other directions, can solve the problems of failure of release paper, insufficient to overcome the adhesion force of buffer block and release paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

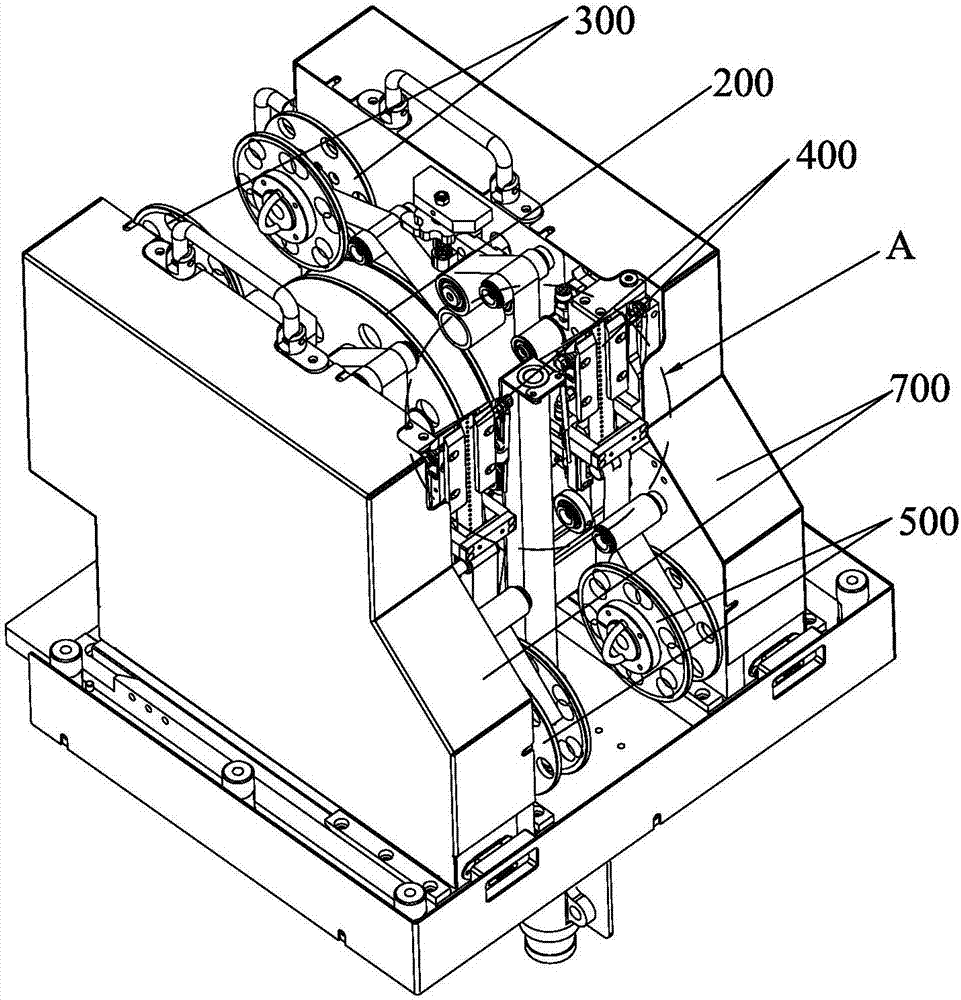

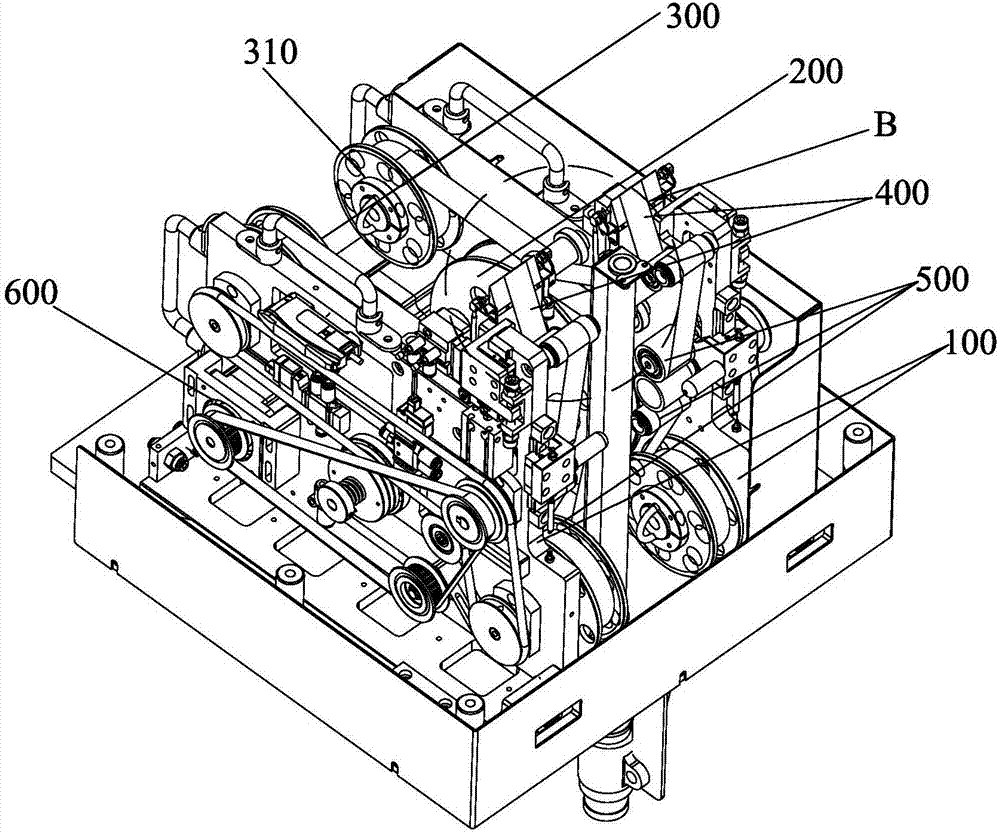

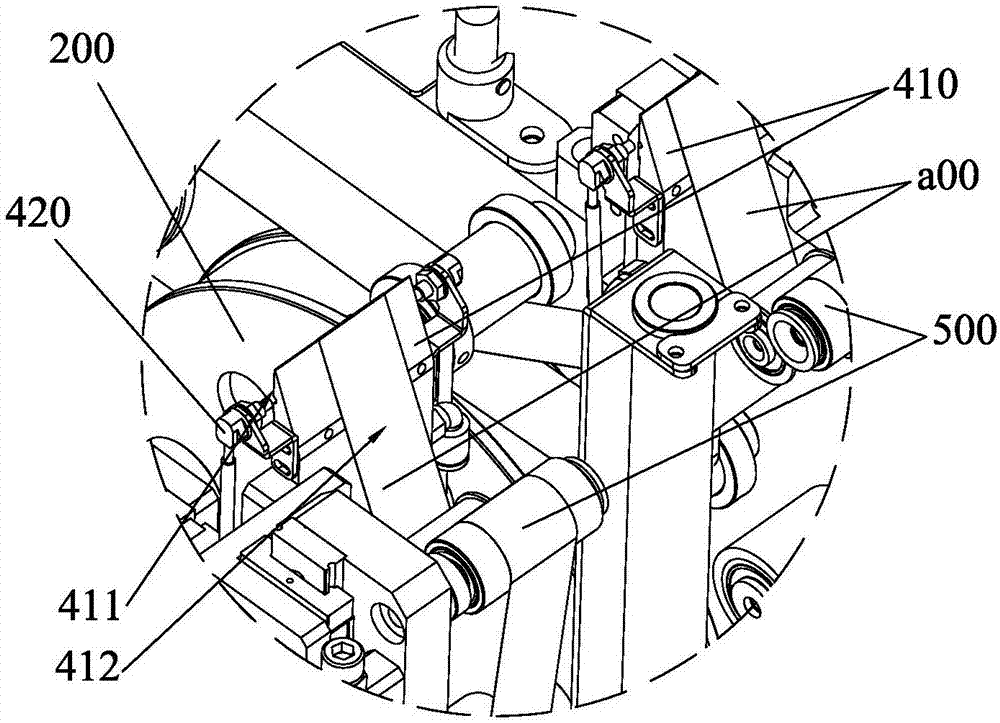

[0022] Such as figure 1 with figure 2 As shown, the buffer block automatic feeding device provided by the present invention is suitable for peeling off several buffer blocks b00 provided on the release paper material belt a00 and realizing automatic feeding of the buffer blocks b00. The buffer block automatic feeding device of the present invention includes a frame 100 , a buffer block feeding mechanism 200 , a tape recovery mechanism 300 , and a separation mechanism 400 respectively arranged on the frame 100 . The release paper material belt a00 protruding from the buffer block feeding mechanism 200 passes through the separation mechanism 400 and is returned to the material belt recovery mechanism 300; The separation block 410 of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com