Sound absorbing and insulating screen structure

A sound-absorbing and insulating panel technology, which is applied to noise-absorbing devices, layered products, buildings, etc., can solve problems such as sound-absorbing, sound-insulating narrow frequency band, difficult cleaning and maintenance of sound-absorbing and insulating screens, and self-heaviness, etc. Weight, strong versatility, overcoming the effect of heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

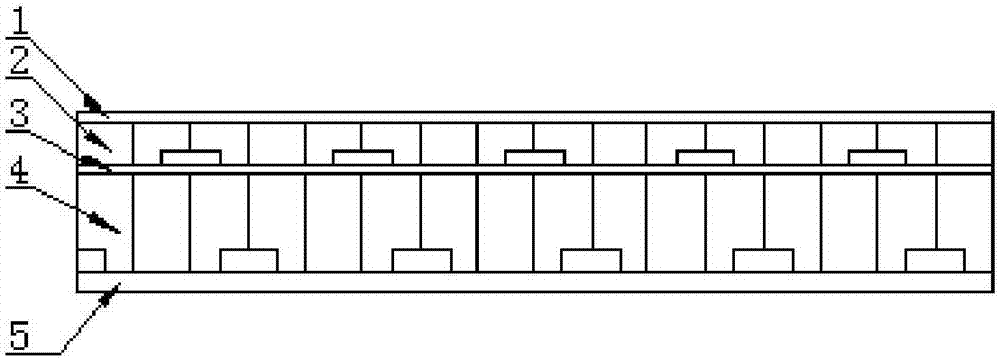

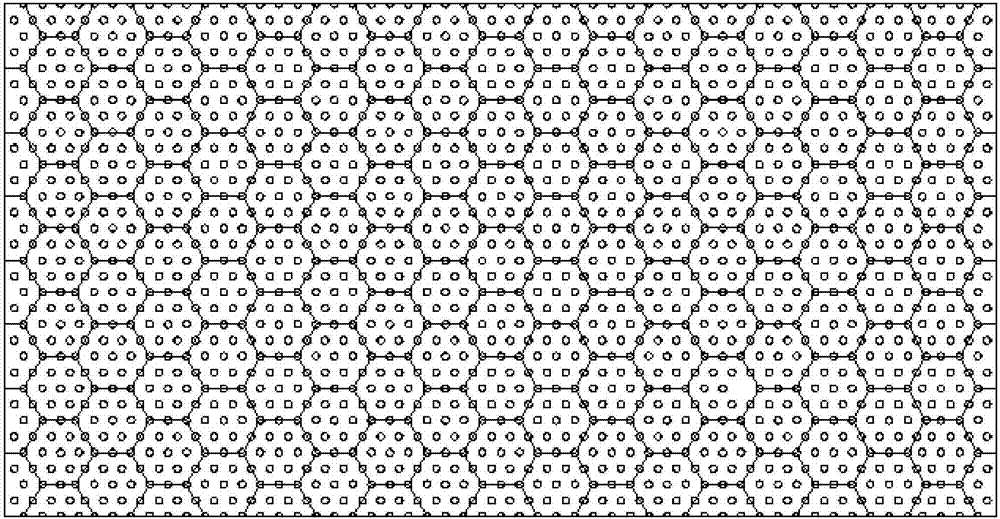

[0031] Such as Figure 1~2 As shown, a sound-absorbing and insulating screen structure includes a first panel 1, a first honeycomb core 2, a second panel 3, a second honeycomb core 4 and a third panel 5; the first panel 1, the first honeycomb core 2, The second panel 3, the second honeycomb core 4, and the third panel 5 are laminated in sequence, the first panel 1 is provided with small holes, and the sides of the first honeycomb core 2 and the second honeycomb core 4 are provided with concave holes for collecting impurities. Groove, the height of the first honeycomb core 2 is not greater than the height of the second honeycomb core 4, the second panel 3 is provided with micropores, the third panel 5 is a solid plate, the small holes and the micropores are the same as the first hon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com