Plate storage rack

A technology for placing racks and plates, applied in tool storage devices, manufacturing tools, etc., can solve the problems of complex operation, low efficiency, and few plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

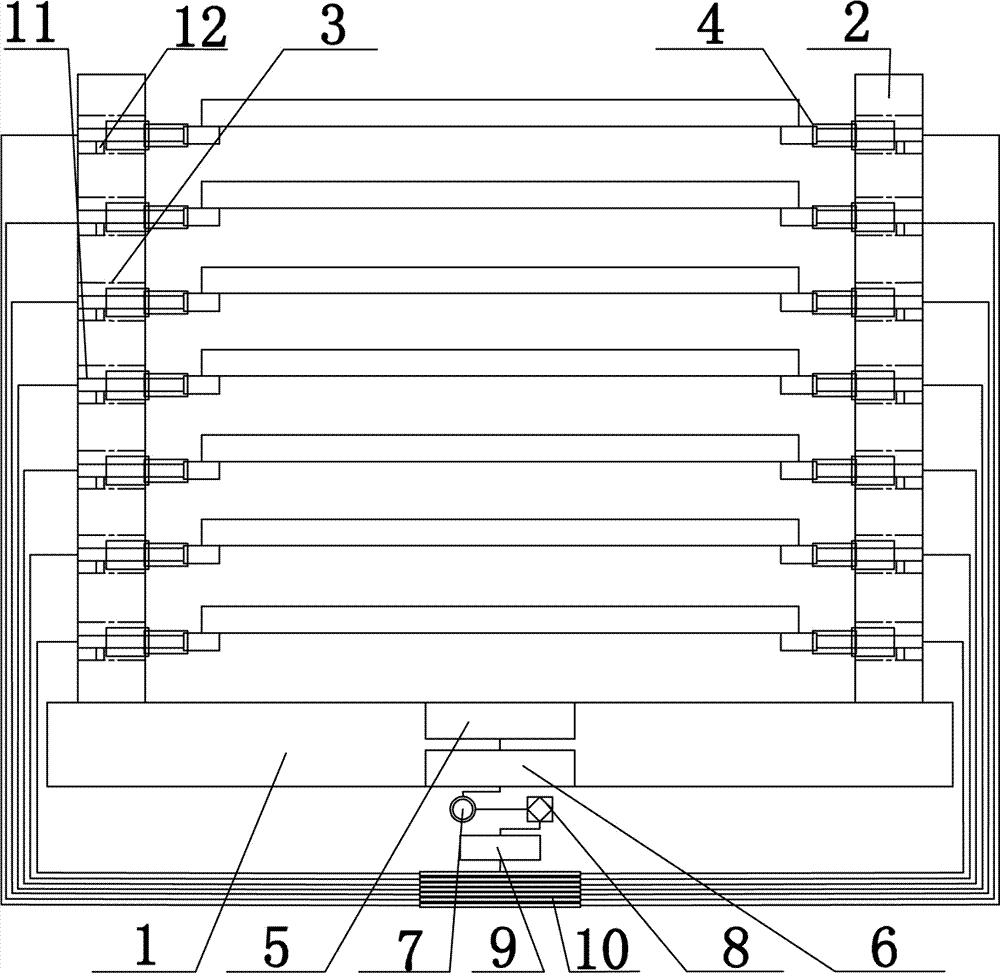

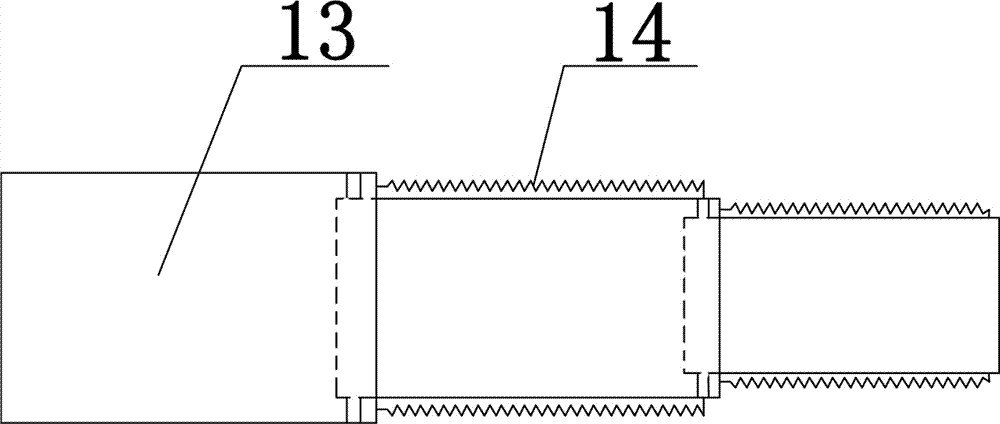

[0019] As shown in the figure, the present invention relates to a panel placing frame, which includes a rectangular bottom frame 1 and four support rods 2 of equal height respectively arranged at the four corners of the bottom frame 1, and the support rods 2 face the bottom One side of the frame 1 is evenly distributed with a number of through holes 3 from top to bottom, and any one of the through holes 3 is provided with a telescopic strut 4; the number of through holes 3 on the four support rods 2 is equal and equidistant Setting; the bottom frame 1 is provided with a gravity sensor 5, the gravity sensor 5 is connected to a controller 6, and the controller 6 is connected to the telescopic support rod 4 through a driving mechanism.

[0020] In the present invention, the overall range of the shelf i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com