Overflow preventing control method of wall-breaking food processer and wall-breaking food processer

A control method and cooking machine technology, applied in the direction of spill prevention, household utensils, applications, etc., can solve the problems of inaccurate and reliable overflow prevention, affect the heating effect, trigger overflow prevention, etc., to reduce the failure of overflow prevention and misjudgment Probability, extended heating time, anti-overflow accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

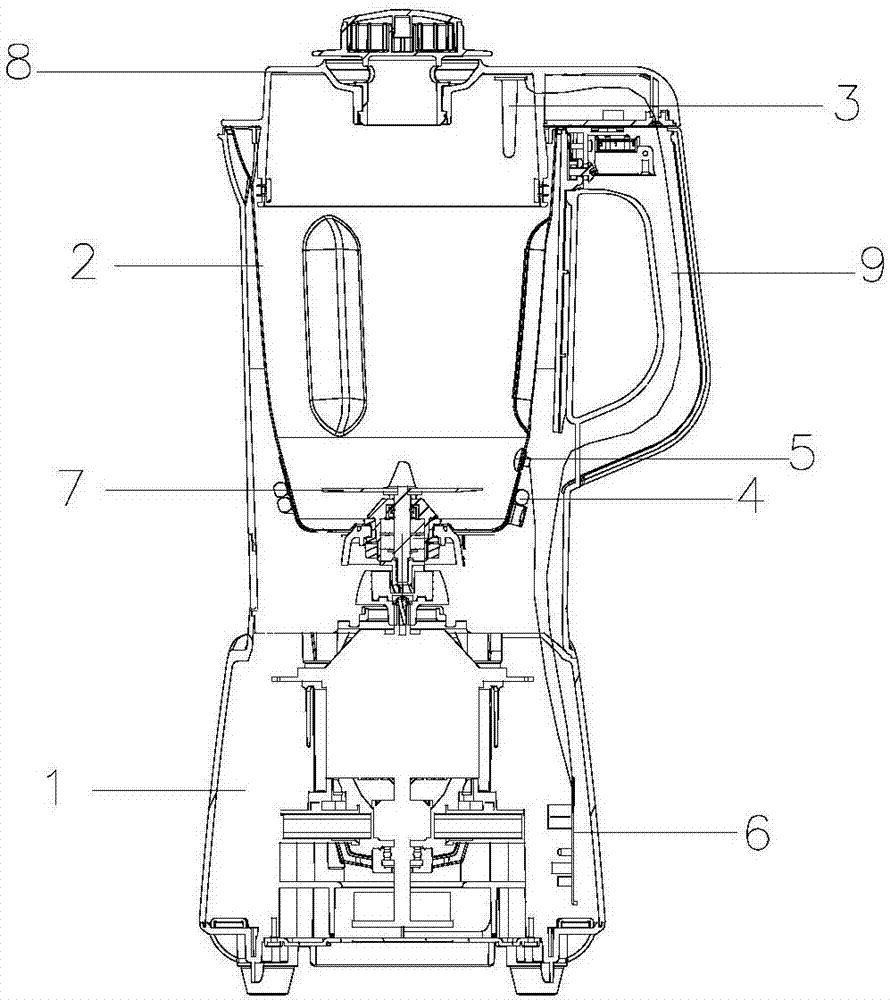

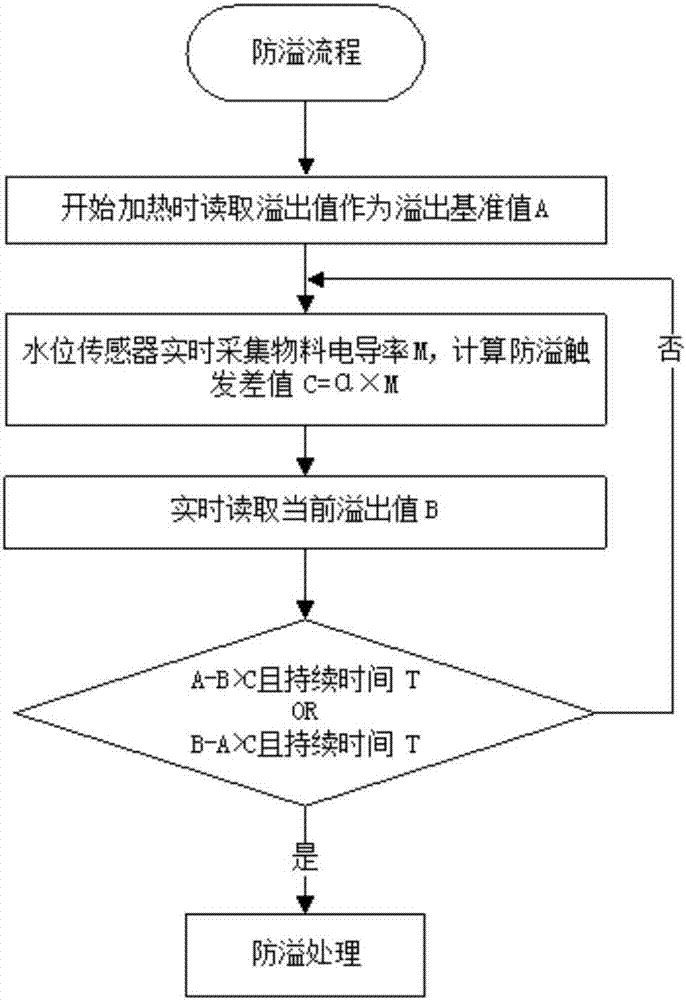

[0031] Such as figure 1 , figure 2 As shown, an anti-overflow control method for a broken wall cooking machine, the cooking machine includes a main control chip, a stirring cup 2, an anti-overflow device 3 and a heating device 4, wherein the cooking machine also includes a water level sensor 5, the The anti-overflow control method at least includes an overflow value reading step: the main control chip (not shown in the figure) reads the overflow value detected by the anti-overflow device 3 as the overflow reference value A, and the overflow reference value A is the starting point for the heating device 4 to start heating. The detection value of the front overflow prevention device 3; the correction step: the water level sensor 5 detects the conductivity of the slurry in the stirring cup 2, and the main control chip calculates and stores the overflow trigger value C according to the conductivity of the slurry, and the conductivity of different slurry is different. The overflo...

Embodiment 2

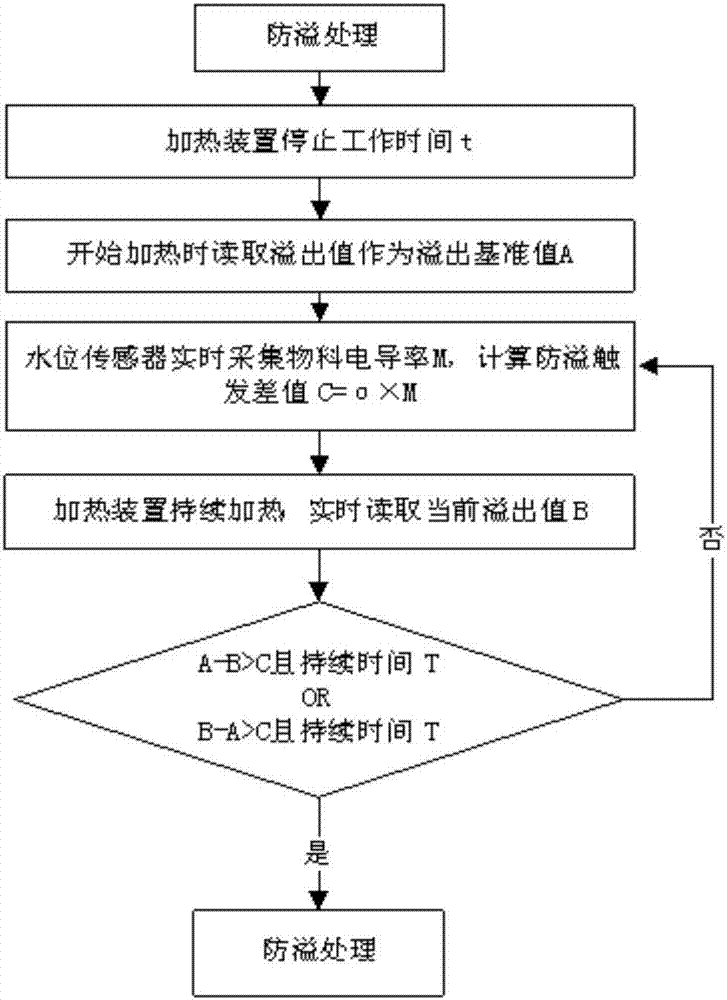

[0041] The difference between Embodiment 2 and Embodiment 1 is that, as image 3 As shown, the anti-overflow control method also includes an anti-overflow review step: after the heating device 4 stops working for a time t, the main control chip controls the heating device 4 to heat the slurry in the stirring cup 2 again, 10s≤t≤50s , in this embodiment, t=40s, that is, the slurry stuck to the overflow prevention device 3 can slide off, preventing the heating device 4 from being unable to start again; it can also prevent nutrient loss and energy loss caused by repeated heating. The anti-overflow review step is repeated at least once, and the overflow value reading step and the correction step are included before the anti-overflow review step. After the heating is turned on again, the overflow trigger value C is corrected and updated in real time through the data measured by the water level sensor 5 . That is to say, the cooking machine pauses for a time t after performing the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com