Industrial method for improving applicability of senior tobacco leaves through module group secondary rebaking

A usability and tobacco leaf technology, applied in the fields of threshing and redrying, tobacco processing, and tobacco leaf treatment, can solve the problems of difficulty in meeting the supply demand of cigarette raw materials, insignificant improvement of tobacco leaf quality, and long cycle, so as to save inventory and raw material costs, improve The effects of heavy and reduced impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

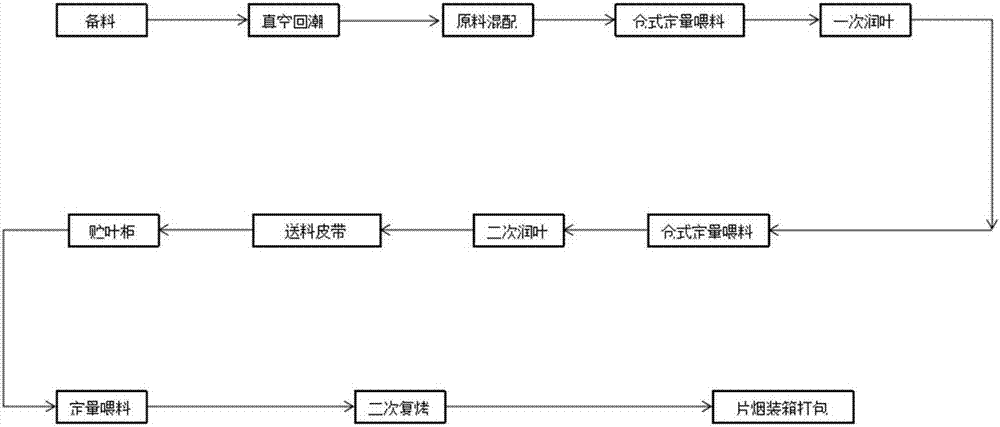

Method used

Image

Examples

Embodiment 1

[0022] The tobacco leaf processing capacity of module A is 8000kg. Vacuum dampening is carried out after preparing materials according to the formula. The raw materials are evenly fed according to the raw material formula, and the tobacco sheets are loosened as much as possible. The leaves are moistened once until the moisture content of the tobacco leaves is 15.0%. Tobacco leaves directly enter the leaf storage cabinet, and the tobacco leaves in the leaf storage cabinet are sent out for secondary re-baking. The temperature of the second re-baking drying zone is 70°C, the temperature of the first zone is 63°C, the temperature of the third zone is 65°C, and the temperature of the fourth zone is 62°C. Set at 6000kg / h, the outlet moisture of tobacco leaves is 11.6%.

[0023] After the second re-baking, the miscellaneous gas of the A module tobacco leaves is reduced, and the comfort is improved. It is compatible with a certain three types of cigarettes, and does not affect the styl...

Embodiment 2

[0025] The tobacco leaf processing capacity of module A is 8000kg. Vacuum dampening is carried out after the raw material is prepared according to the formula. Tobacco leaves directly enter the leaf storage cabinet, and the tobacco leaves in the leaf storage cabinet are sent out for secondary rebaking. The temperature of the second rebaking and drying zone is 75°C, the temperature of the first zone is 65°C, the temperature of the third zone is 69°C, and the temperature of the fourth zone is 65°C. 6000kg / h is set, and the moisture content of tobacco leaves is 11.5%.

[0026] After the second rebaking, the miscellaneous gas of the A module tobacco leaves is significantly reduced, and the smoke fragrance is slightly weakened. It is used in compatibility with a certain four types of cigarettes, without affecting the style, smoke, smoke, and miscellaneous gas of the brand of cigarettes. Under conditions such as stimulation, it is advisable to add the ratio not higher than 15%.

Embodiment 3

[0028] The tobacco leaf processing capacity of module B is 8000kg. Vacuum dampening is carried out after preparing materials according to the formula. The raw material formula is evenly fed, and the tobacco sheets are loosened as much as possible. The tobacco leaves directly enter the leaf storage cabinet, and the tobacco leaves in the leaf storage cabinet are sent out for secondary re-baking. The temperature of the second re-baking drying zone is 78°C, the temperature of the first zone is 68°C, the temperature of the third zone is 69°C, and the temperature of the fourth zone is 65°C. Box moisture 11.5%.

[0029] After the second re-baking, the mixed gas of the B-module tobacco leaves is reduced, the stimulation is weakened, the aftertaste is clean, and the oral residue is reduced. It is compatible with a certain four types of cigarettes, without affecting the style, smoke, and aroma of the cigarettes of this brand. Under the conditions of miscellaneous gas and irritation, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com