Peanut Sheller

A shelling machine and peanut technology, applied in the field of agricultural machinery, can solve the problems of high shelling force, low efficiency, and influence on sales, and achieve the effects of reducing the breaking rate, improving the shelling quality, and avoiding breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

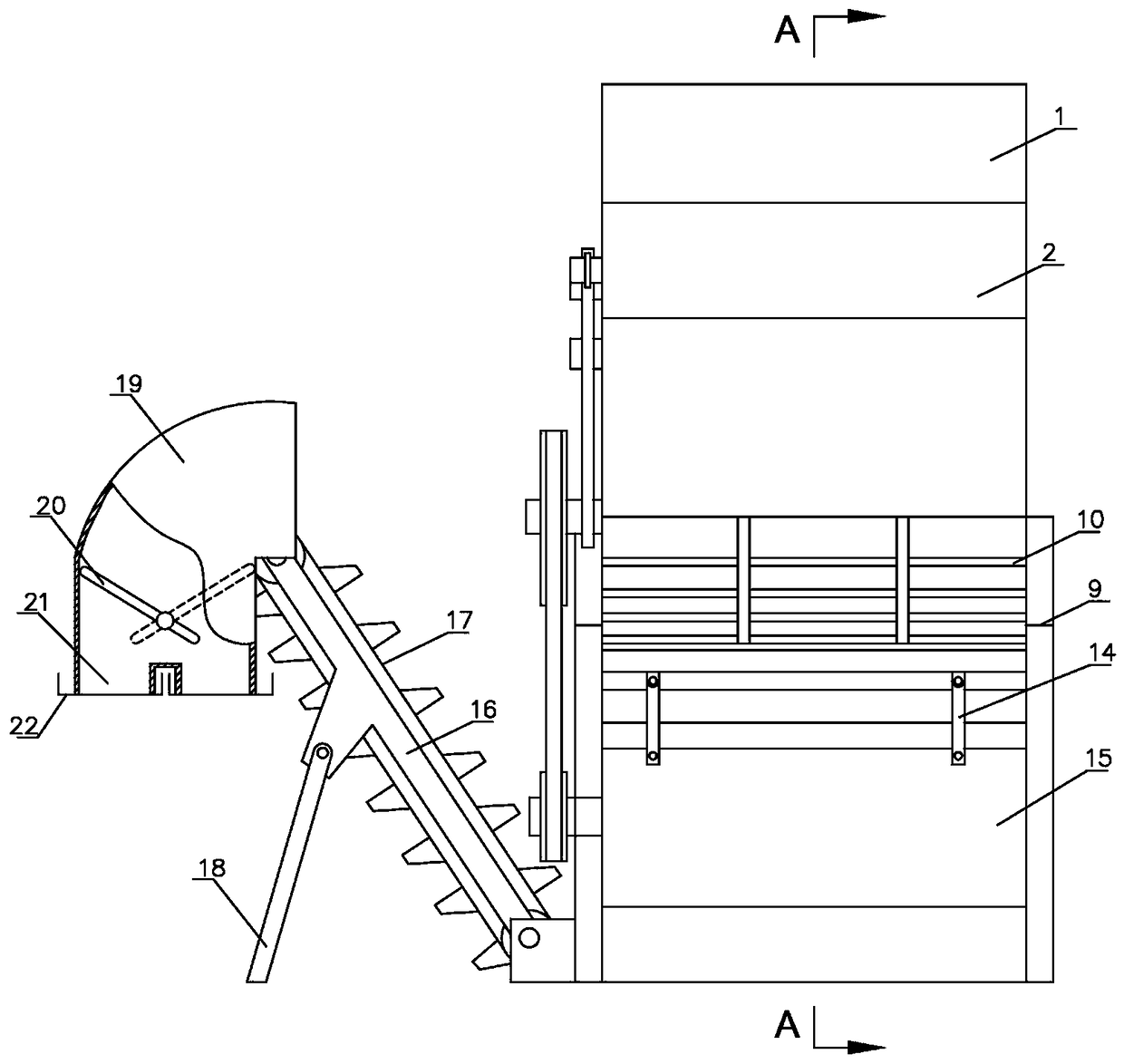

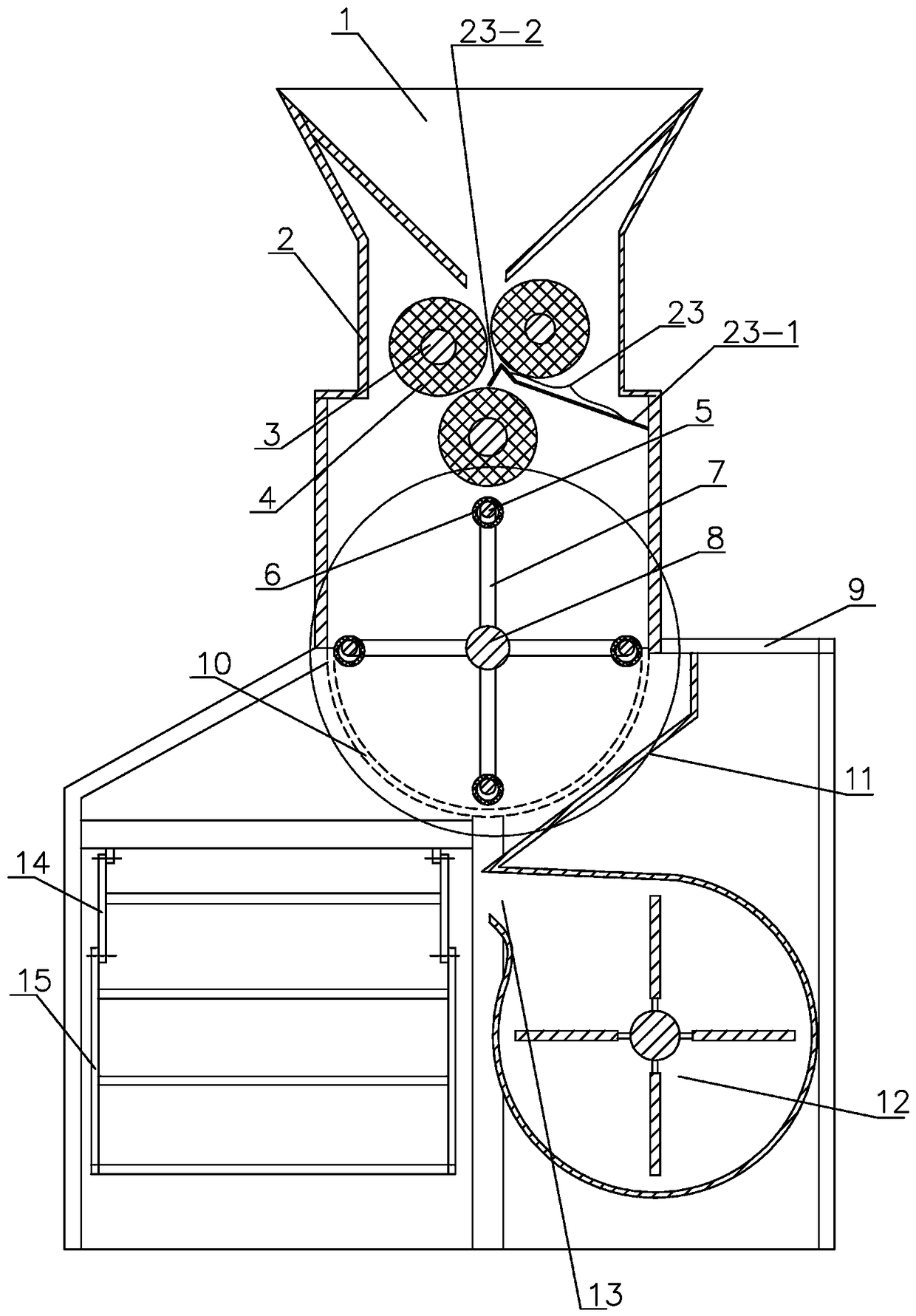

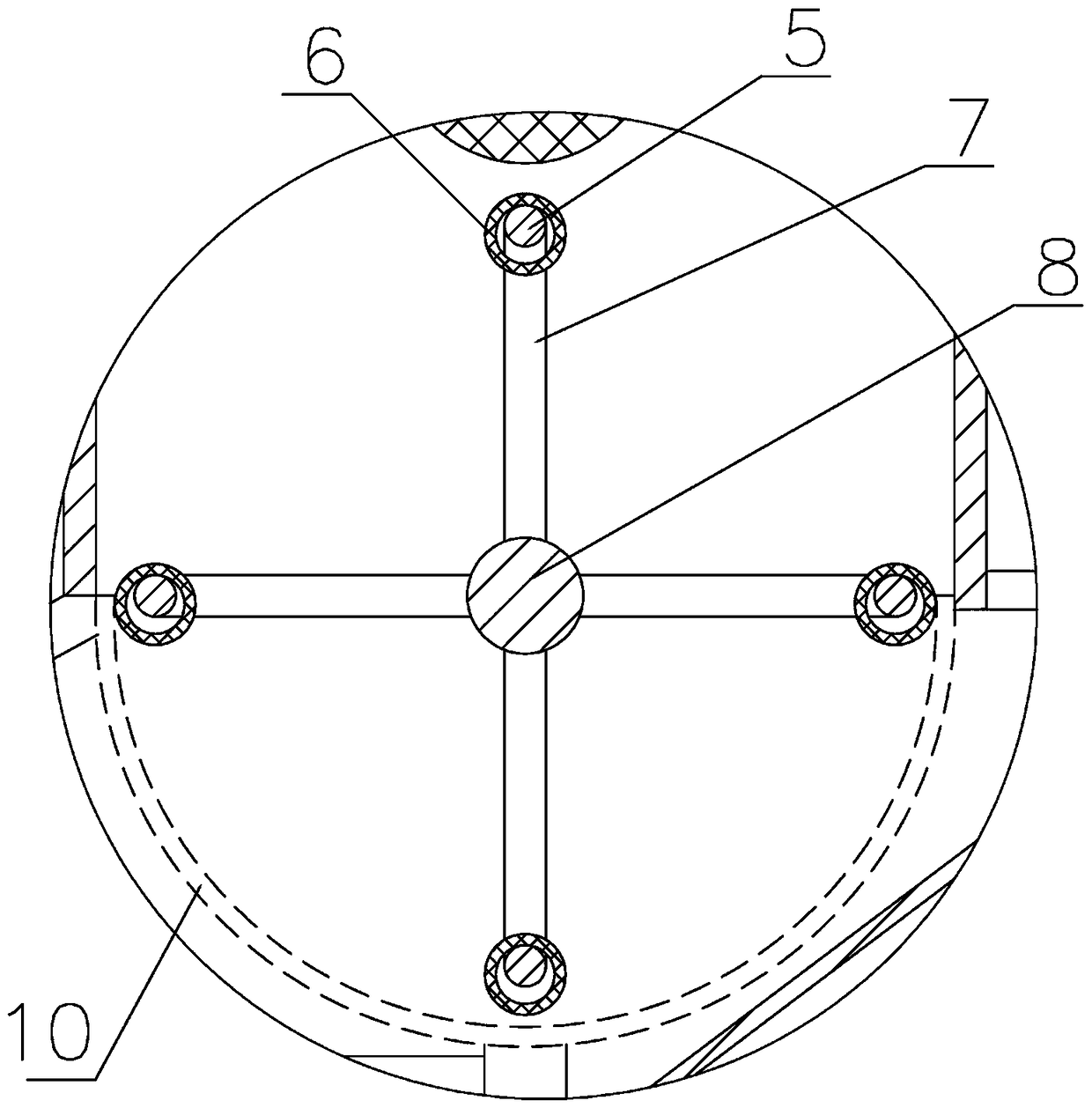

[0027] The specific embodiment of the present invention sees Figure 1-12 , a peanut shelling machine, comprising an upper hopper and a frame below the upper hopper, between the upper hopper and the frame, a shelling bin with a semicircular coarse sieving plate at the bottom, the The upper hopper is a conical structure with an open lower end. The junction of the upper hopper and the shelling bin is provided with three crushing shafts arranged in a triangular gap. The upper crushing shaft is located slightly to the right of the middle crushing shaft. The upper position, the lower crushing shaft is located directly below the contact surface of the upper crushing shaft and the middle crushing shaft, and a 7-shaped multifunctional plate, the right end of the multifunctional plate is fixed on the inside of the right wall of the shelling bin, the front end and the rear end of the multifunctional plate are respectively fixed on the inside of the front wall and the rear wall of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com