New-type composite loudspeaker diaphragm

A loudspeaker and composite technology, which is applied in the field of new composite speaker diaphragms, can solve the problems of insufficient support, insufficient sound quality, unfavorable miniaturization, etc., and achieve the effect of improving structural support and sound quality performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

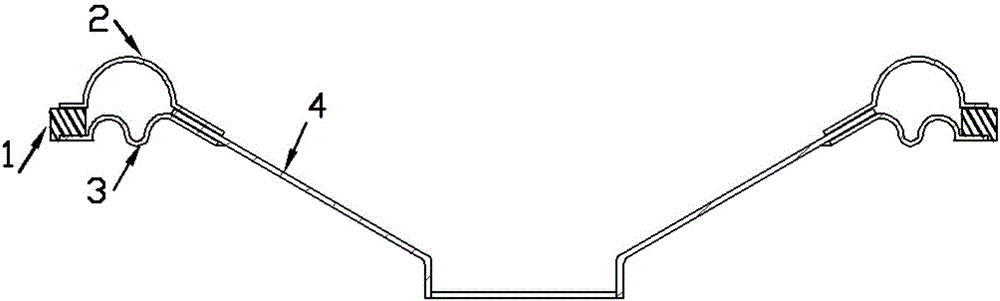

[0044] Such as Figure 1-6 As shown in , the diaphragm body 4 is an inverted cone; the bonding and combination process of its assembly is as follows: respectively use the preferred customized mold to respectively connect the upper ring 2 with the inverted cone diaphragm body 4 and the lower ring 3 Carry out positioning bonding with the sealing gasket 1 made of plastic material, and then put the semi-finished product of the upper ring 2 and the inverted cone diaphragm body 4, the semi-finished product of the lower ring 3 and the sealing gasket 1 into the customized mold to complete the positioning and Final gluing is done.

[0045] In this process, customized molds can also be used to respectively position and bond the upper ring 2 and the sealing gasket 1, the lower ring 3 and the inverted cone diaphragm body 4, and then the semi-finished products of the upper ring 2 and the sealing gasket 1 , The semi-finished products of the lower ring 3 and the inverted conical diaphragm b...

Embodiment 2

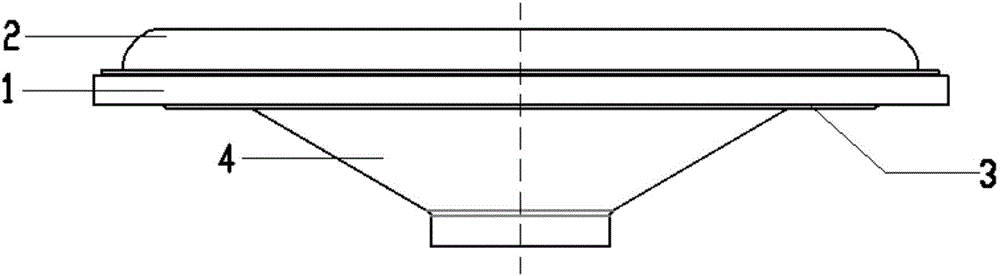

[0048] Such as Figure 7-9 As shown in , the diaphragm body 4 is a raised spherical arcuate body; the bonding combination process of its assembly is: using a preferred customized mold to position and glue the integrally formed upper and lower rings and the spherical diaphragm body 4 Then put them together with the plastic sealing gasket 1 into a customized mold to complete the positioning and bonding; this process can also use a customized mold to position and bond the integrally formed upper and lower rings and the sealing gasket 1, and then with The spherical diaphragm body 4 is placed together into a customized mold to complete positioning bonding.

[0049] In this embodiment, when the upper ring 2 is an upwardly convex hemispherical arc, the optional shape of the matched lower ring 3 is: an upwardly convex hemispherical arc, a downwardly concave hemispherical Arc shape; when the upper ring 2 is a downwardly recessed hemispherical arc, the matched lower ring 3 is a downwar...

Embodiment 3

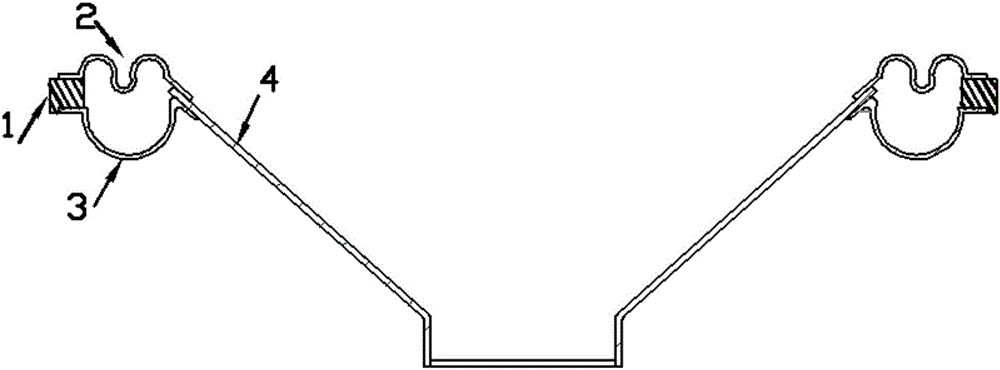

[0051] Such as Figure 10-12 As shown in , the diaphragm body 4 is a circular plane.

[0052] In this embodiment, when the upper ring 2 is an upwardly convex hemispherical arc, the optional shape of the matched lower ring 3 is: an upwardly convex hemispherical arc, a downwardly concave hemispherical Arc shape; when the upper ring 2 is a downwardly recessed hemispherical arc, the matched lower ring 3 is a downwardly recessed hemispherical arc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com