Variable turn-number flat-wire motor stator winding

A motor stator and flat wire technology, applied to the shape/style/structure of winding conductors, can solve the problems of waste of materials and space, and achieve the effects of avoiding materials and space, rapid switching process, and preventing power interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

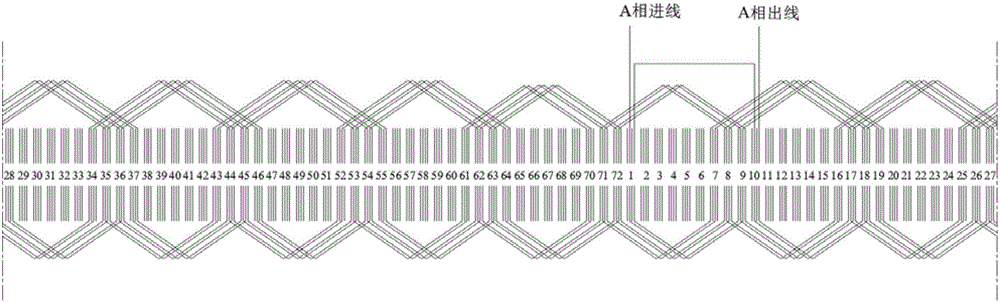

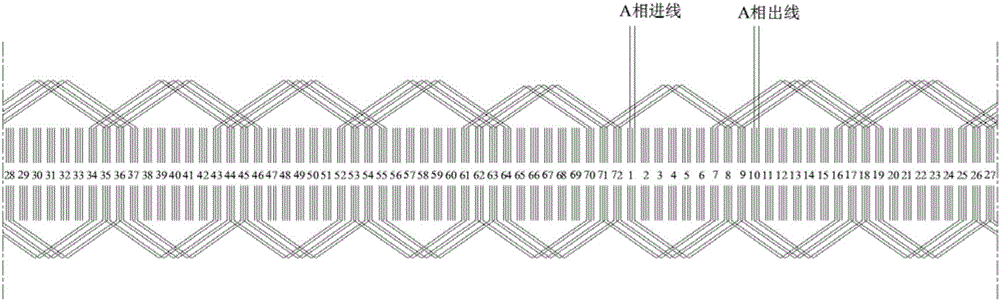

[0029] see figure 1 and figure 2 , the structural form of the stator winding of the variable number of turns flat wire motor in this embodiment is: for the stator winding of the four-layer flat wire motor, a winding wiring switching device is set, and the winding wiring switching device is used to make each phase of the stator winding run at a low speed of the motor. Switch to one connection in series, the number of turns of the stator winding in one connection in series is 2N, such as figure 1 As shown; when the motor is running at high speed, switch to the two-way parallel connection form, and the number of stator winding turns in the two-way parallel connection form is N, such as figure 2 shown.

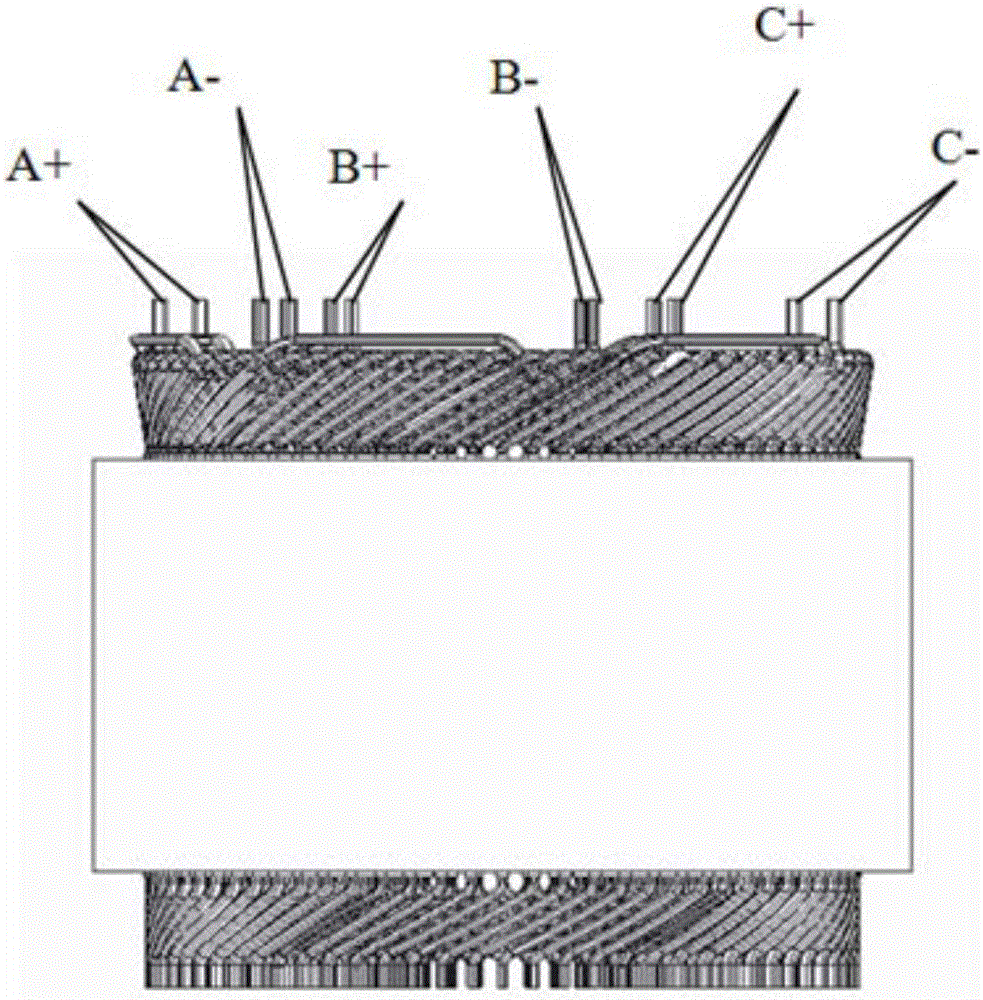

[0030] This embodiment is aimed at the stator winding of a three-phase four-layer flat wire motor, the number of coils in series for each phase is 48, and the number of coils in parallel for each phase is 24. The three-dimensional structure of the stator winding is as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com