Topology optimization method for thermal structure of anisotropic materials based on meshless rkpm

An anisotropic and topology optimization technology, applied in the field of optimization design in computer-aided engineering, can solve problems such as numerical instability, achieve high reliability, good theoretical research and engineering application value, and simple calculation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

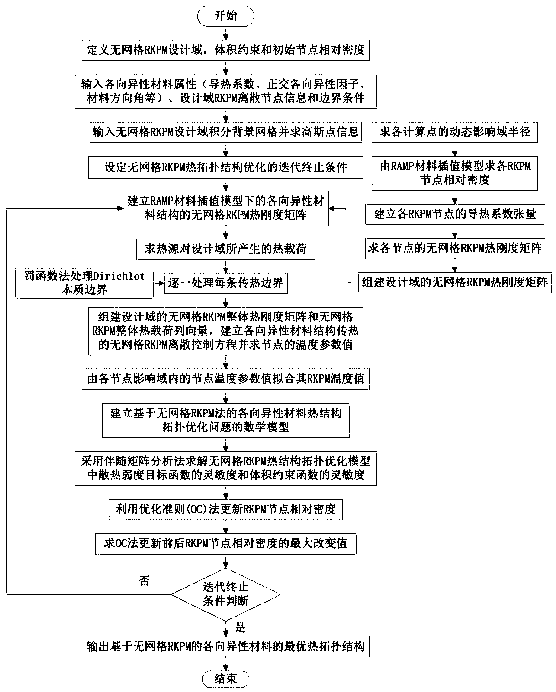

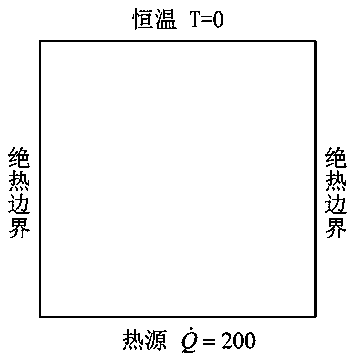

[0031] see figure 1 and figure 2 , the topology optimization method of anisotropic material thermal structure based on meshless RKPM mainly includes the following steps:

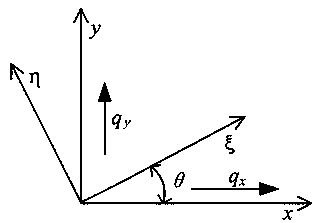

[0032] First, determine the thermal conductivity, orthotropic factor λ, anisotropic material orientation angle θ physical properties of the anisotropic material, and establish a transformation matrix for the thermal properties of the anisotropic material so that the thermal conductivity in the material coordinate system Associated with the design domain geometry coordinate system. Such as figure 1 As shown, the thermal conductivity of anisotropic materials has obvious directionality. Assuming the design domain geometric Cartesian coordinate system (x, y) and material coordinate system (ξ, η), the heat flux along the geometric coordinate axis direction is

[0033]

[0034]

[0035] In the above formula, k ij (i,j=1,2) is the thermal conductivity coefficient that varies with the geometric coordinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com