Multi-direction collision energy-gathering multi-point initiation method for reducing the foundation of deep hole bench blasting

A technology of step blasting and multi-point initiation, which is applied in the field of blasting, can solve problems such as high occurrence rate of step blasting roots, increase equipment wear and failure, and affect normal production, so as to be suitable for large-scale promotion and use, reduce dust, Improves the effect of blasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

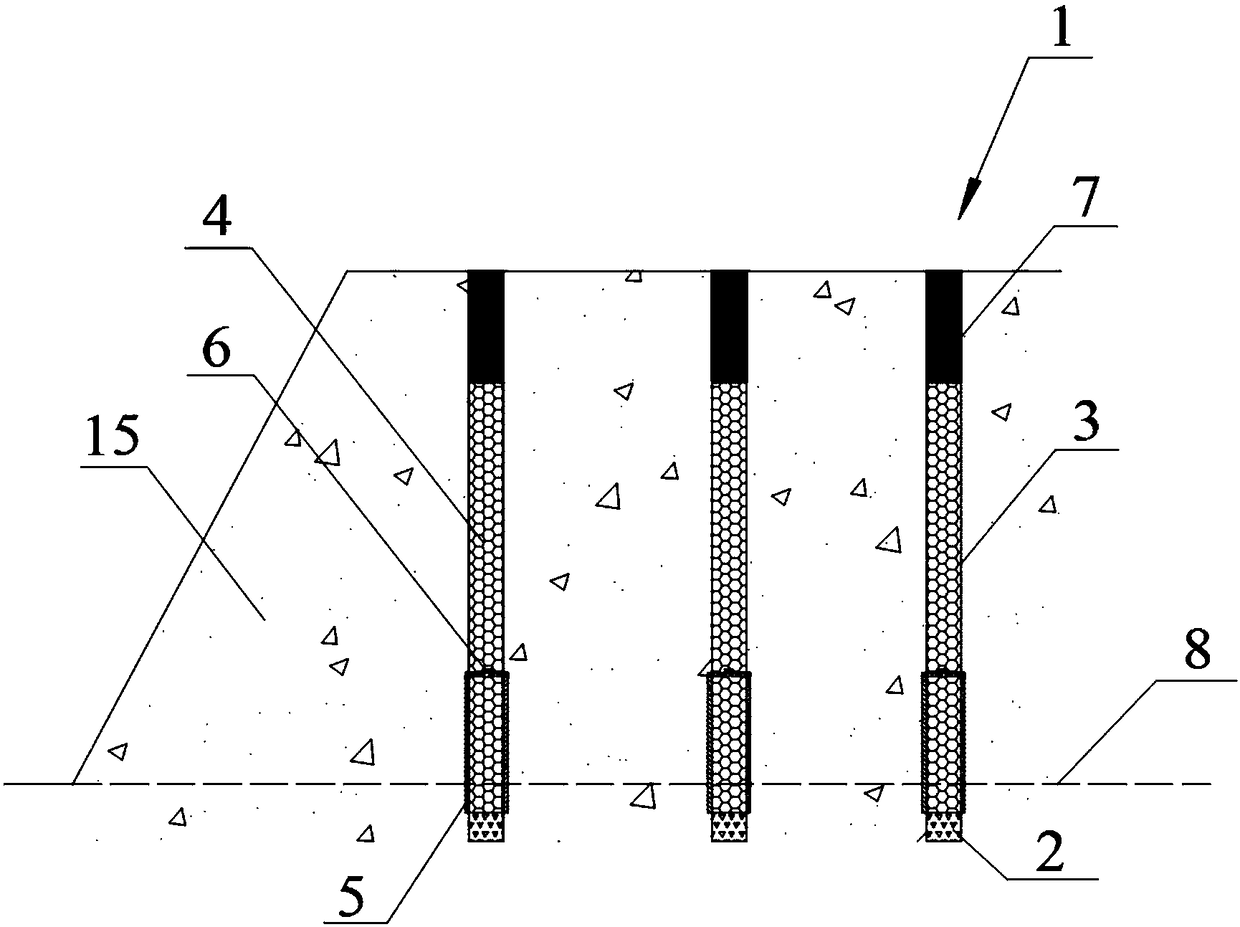

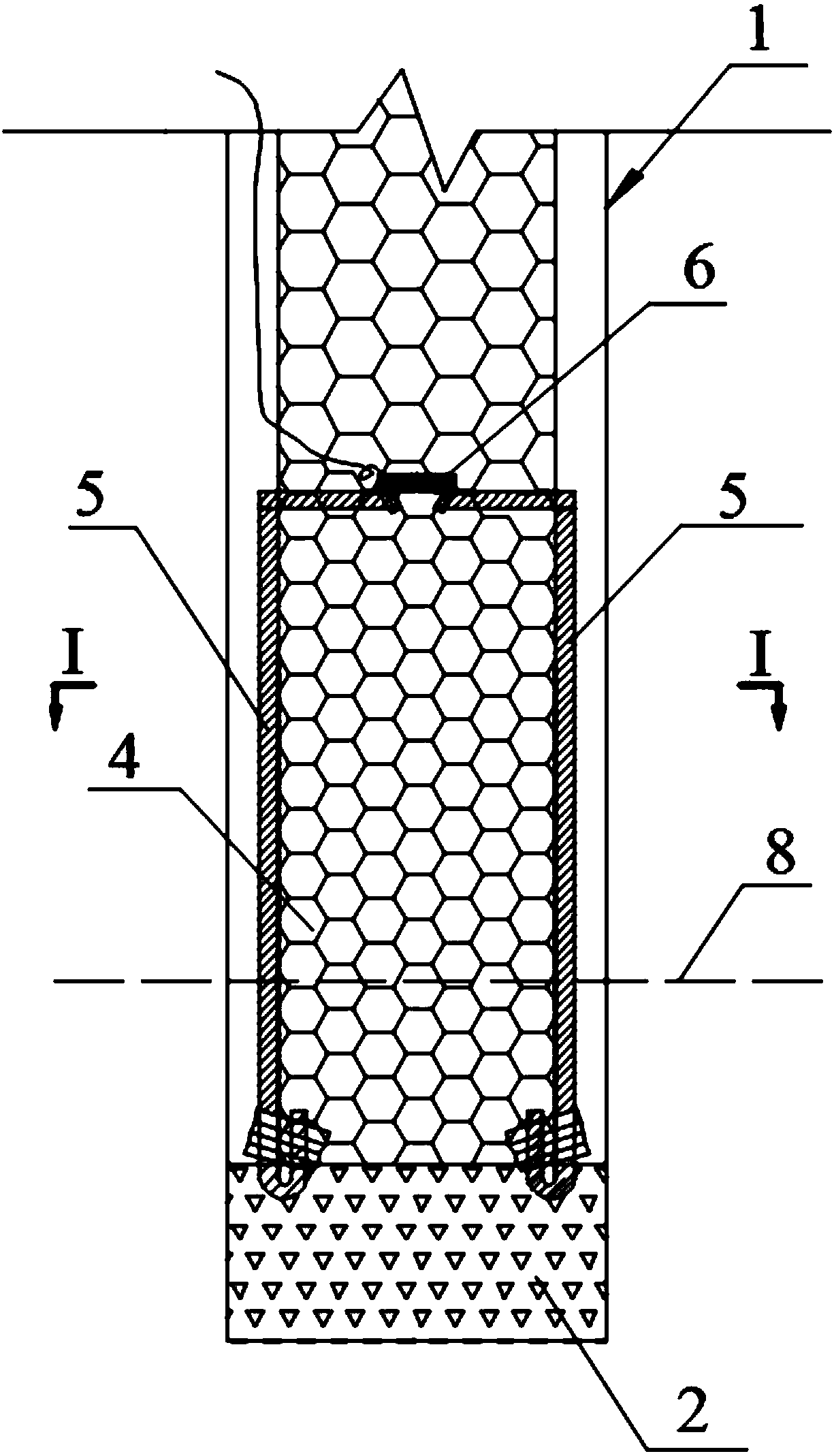

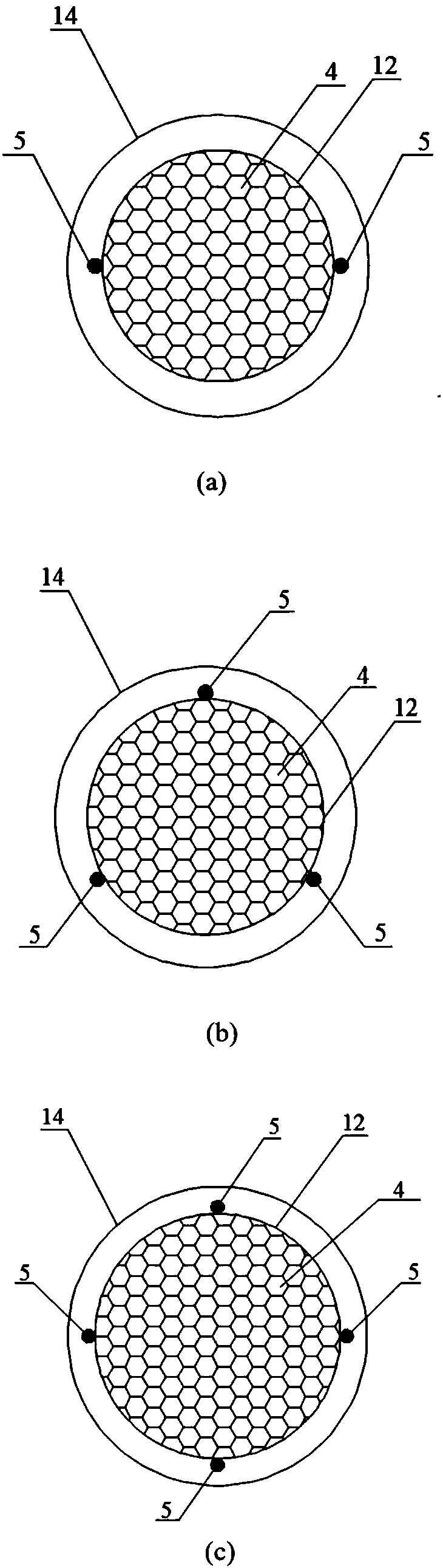

[0028] Aggregate mining project of a hydropower station needs to reduce the blasting foundation in the deep hole step blasting. The blasting design is: vertical drilling, the drilling depth is 10m, the bottom of the hole is over-excavated, the over-excavation depth is 1m, and the drilling diameter is 76mm. The hole spacing is 2.0-2.5m, and the middle detonation method is adopted. like Figure 1~3 As shown in (a), the specific implementation steps of blasting by adopting the multi-directional collision energy-gathering multi-point detonation method that reduces the blasting root in the present embodiment one are as follows:

[0029] S1. Drilling steps:

[0030] Firstly, manually or mechanically remove the overburden layer on the surface of the rock foundation to level the site;

[0031] Then blow the surface with a high-pressure air pipe, and blast the blast hole 1 ( figure 1 Only 3 blastholes are shown in the picture 1) Stake out hole by hole, and the points are marked with...

Embodiment 2

[0047] The aggregate mining project of a hydropower station needs to reduce the blasting foundation in the deep hole step blasting. The blasting design is: vertical drilling, the drilling depth is 10m, the super depth is 1m, the drilling diameter is 90mm, and the hole spacing is 2.0-2.5m , using an intermediate detonation method. like figure 1 , 2 Shown in and 3 (b), in the present embodiment two, adopt the multi-directional collision energy-gathering multi-point detonation method that reduces blasting foundation to carry out the specific implementation steps of blasting as follows:

[0048] S1. Drilling steps:

[0049] Firstly, manually or mechanically remove the overburden layer on the surface of the rock foundation to level the site;

[0050] Then blow the surface with a high-pressure air pipe, and blast the blast hole 1 ( figure 1 Only 3 blastholes are shown in the picture 1) Stake out hole by hole, and the points are marked with red paint;

[0051] Then, in the blast...

Embodiment 3

[0062] The aggregate mining project of a hydropower station needs to reduce the blasting foundation in the deep hole step blasting. The blasting design is: vertical drilling, the drilling depth is 10m, the super depth is 1m, the drilling diameter is 105mm, and the hole spacing is 2.0-2.5m , using an intermediate detonation method. like figure 1 , 2 Shown in and 3 (c), in the present embodiment three, adopt the multi-directional collision energy-gathering multi-point detonation method that reduces blasting foundation to carry out the specific implementation steps of blasting as follows:

[0063] S1. Drilling steps:

[0064] Firstly, manually or mechanically remove the overburden layer on the surface of the rock foundation to level the site;

[0065] Then blow the surface with a high-pressure air pipe, and blast the blast hole 1 ( figure 1 Only 3 blastholes are shown in the picture 1) Stake out hole by hole, and the points are marked with red paint;

[0066] Then, in the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com