An inner tube placement device for combined fireworks

A technology for combining fireworks and placing devices, which is applied in the direction of pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of difficult insertion of the inner cylinder, damage of the outer cylinder, and difficulty in the mechanization and automatic operation of the inner cylinder, so as to achieve reliable and efficient work. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

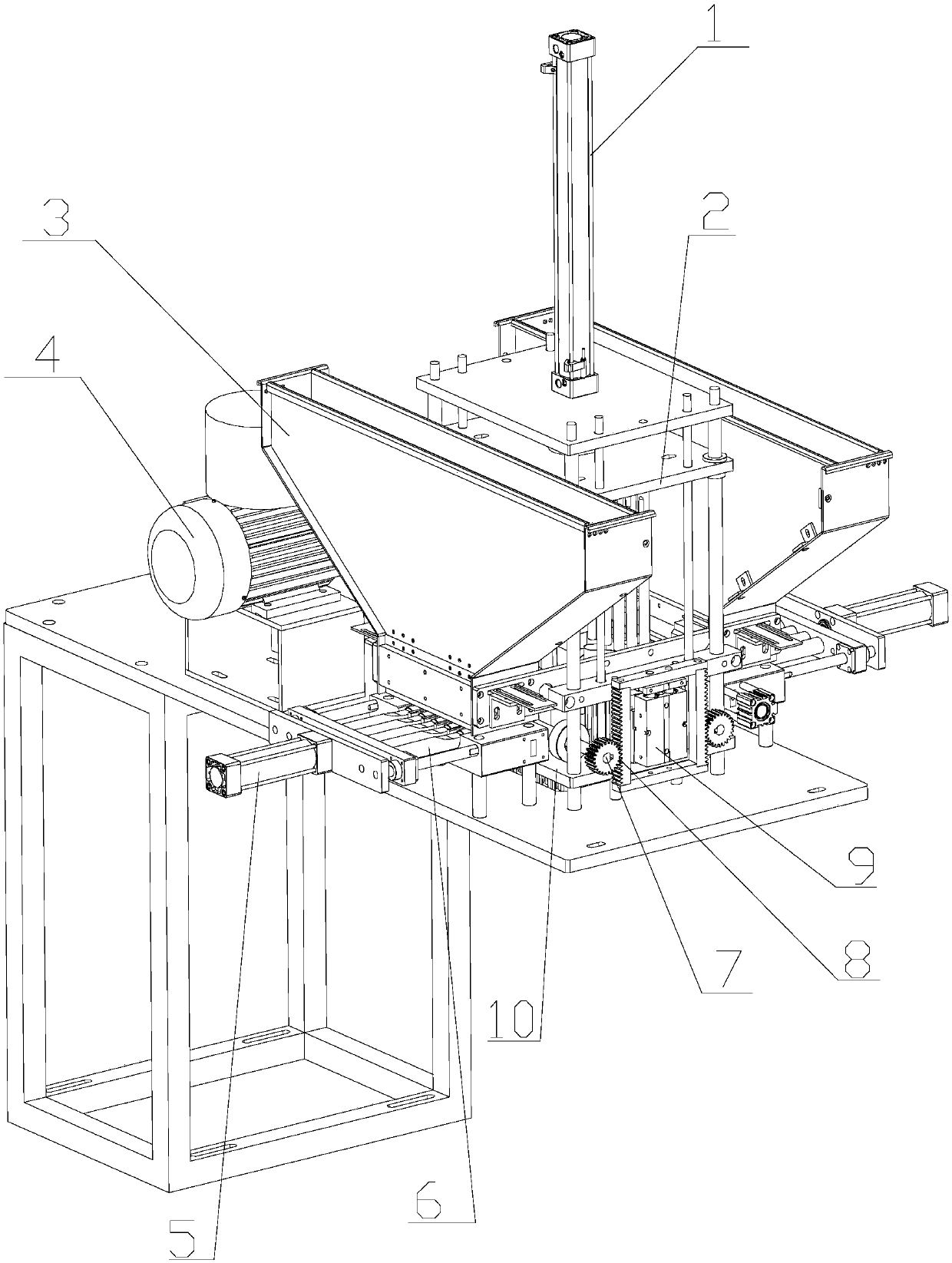

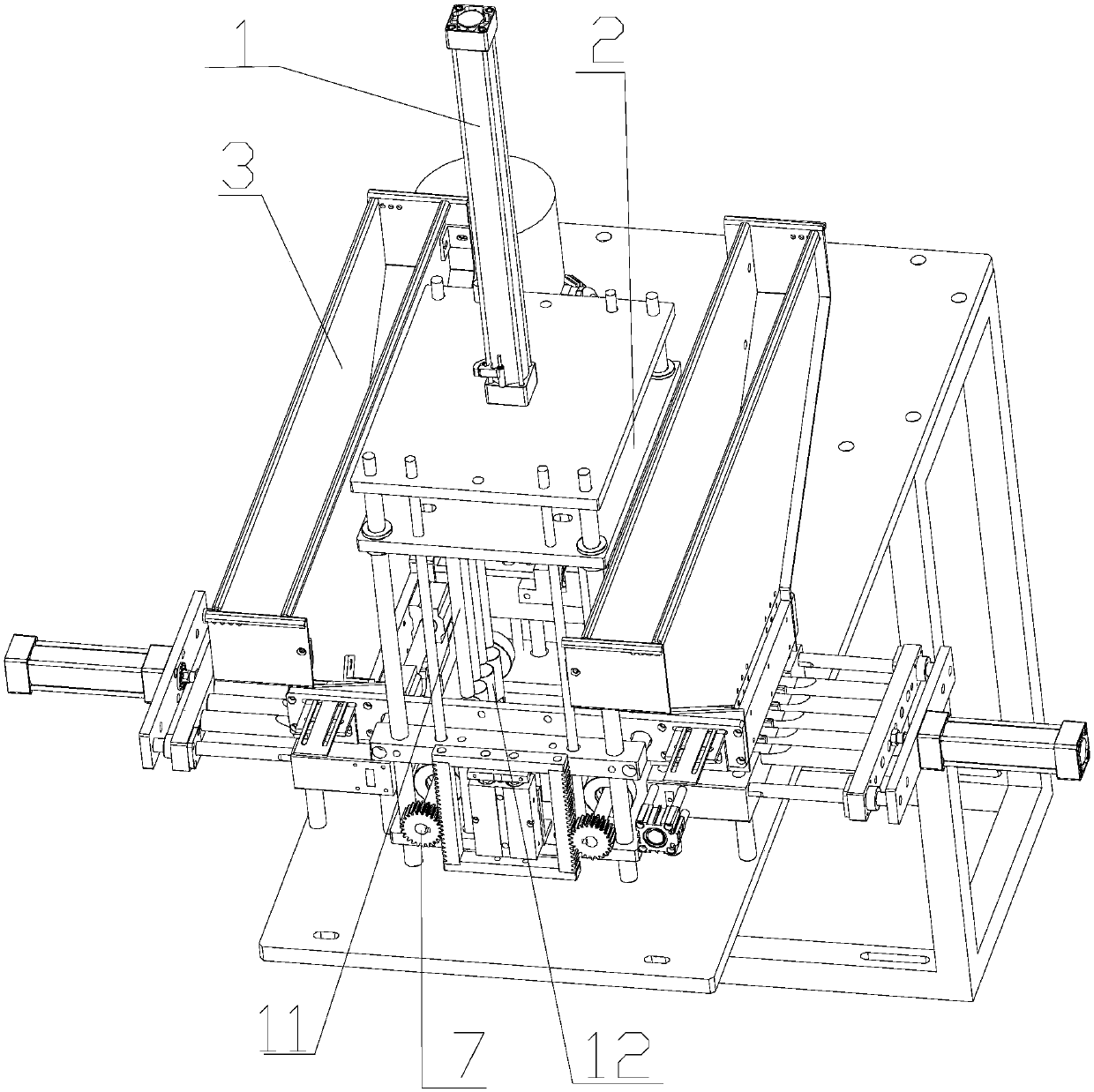

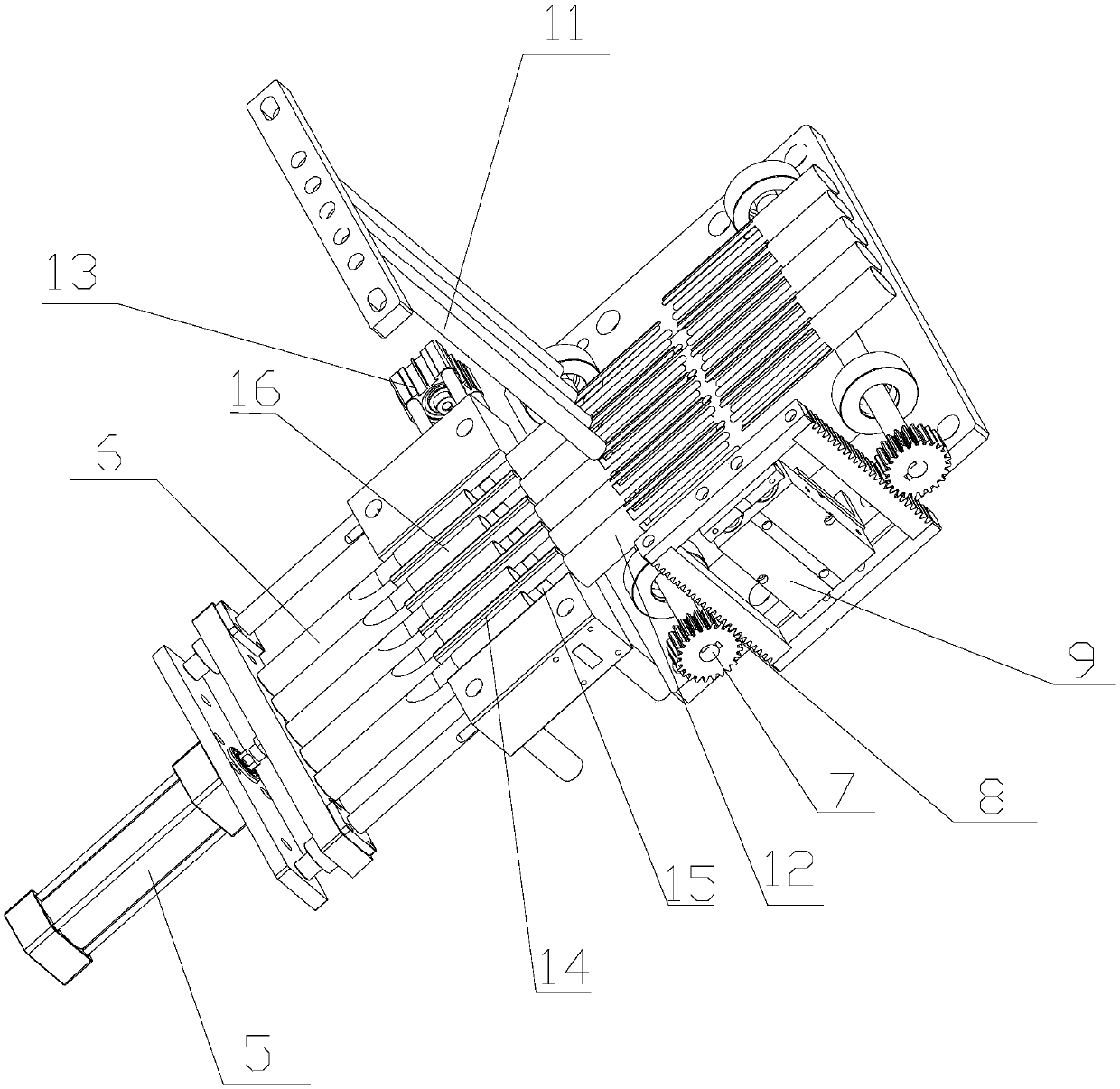

[0017] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the inner cylinder placement device of the combined fireworks includes a lower pressure rod 11 that moves up and down, and the lower pressure rod 11 is connected to the first linear reciprocating drive cylinder 1 through the first base plate 2 , also includes a guide component composed of a dynamic link between the forward guide and the rotating guide:

[0018] The forward guide includes five transverse grooves 14 that only allow a single inner cylinder 16 to pass through in the axial direction. The five transverse grooves 14 are arranged side by side, and the notches of the transverse grooves 14 accept the discharge of the lower hopper 3. mouth, the lower hopper 3 is connected to the swing vibration drive mechanism 4.

[0019] The rear end of each transverse groove body 14 is correspondingly provided with a push rod 6, and the push rod 6 is connected to the second linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com