General purpose engine

A general-purpose engine and engine technology, applied to engine components, engine cooling, machine/engine, etc., can solve the problems of large number of components, increased cost, and reduced operability of blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

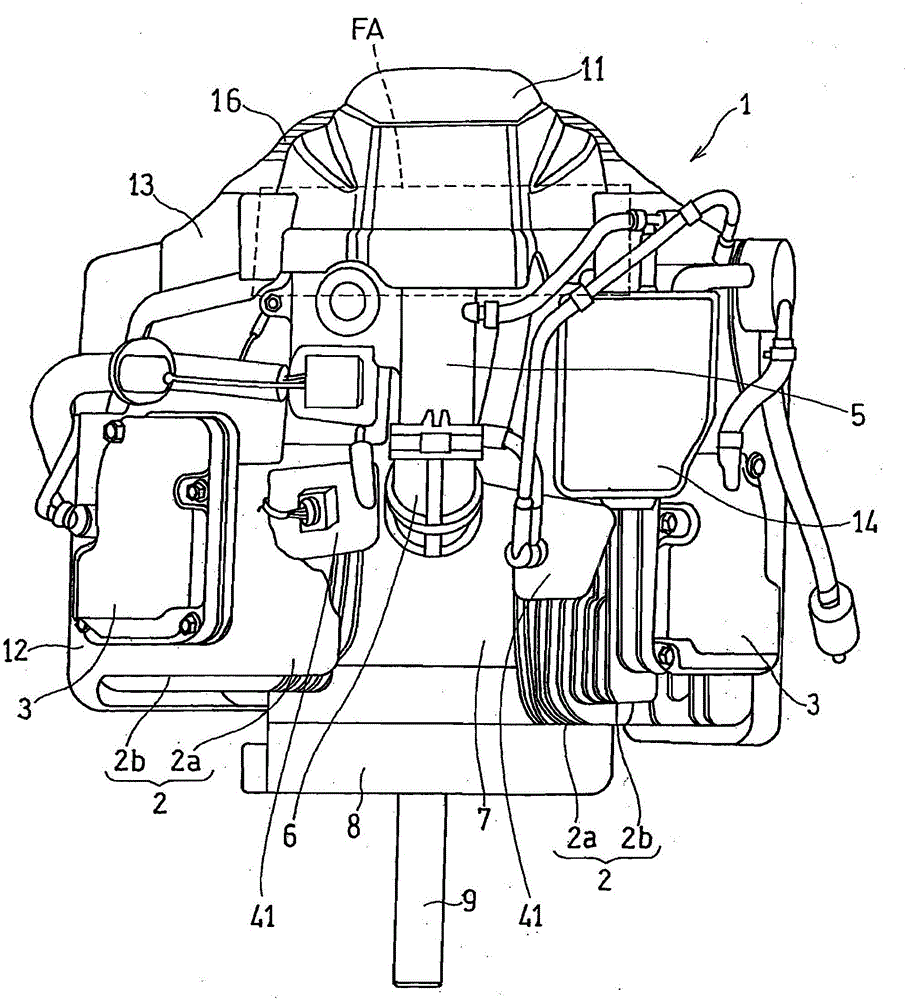

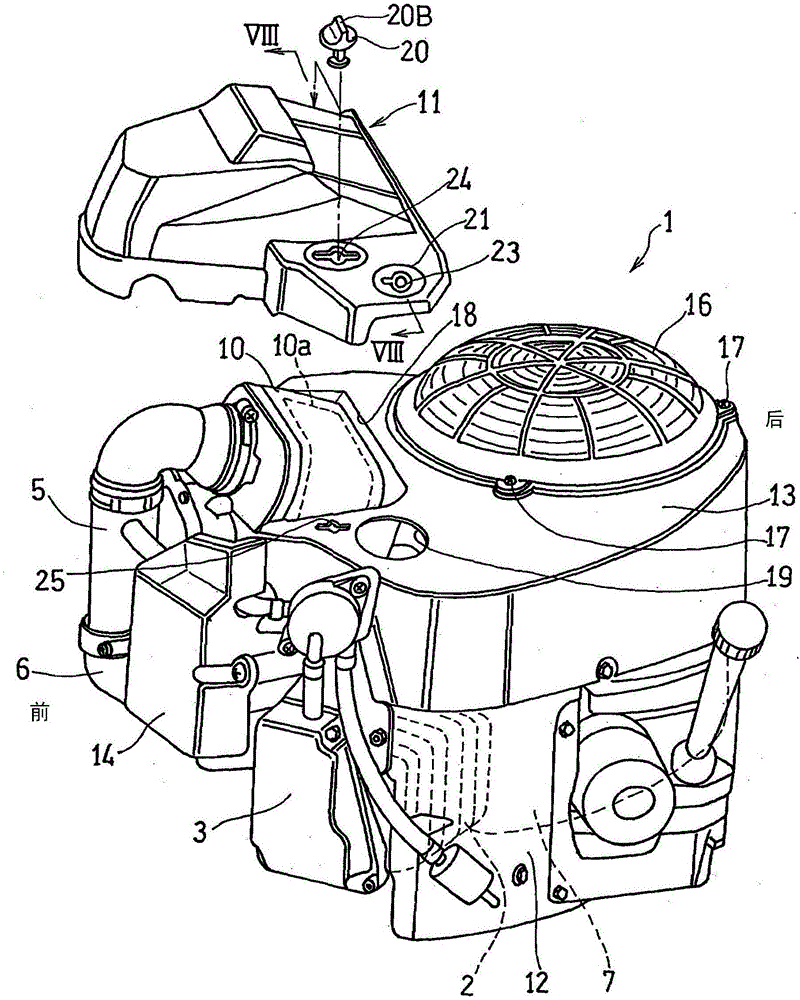

[0038] Hereinafter, one embodiment of the present invention will be described with reference to the drawings. figure 1 It is a front view showing a schematic configuration of a general-purpose engine according to an embodiment of the present invention. figure 1 The illustrated general-purpose engine 1 is a small air-cooled two-cycle engine, and is used as a drive source for a working machine such as a lawnmower.

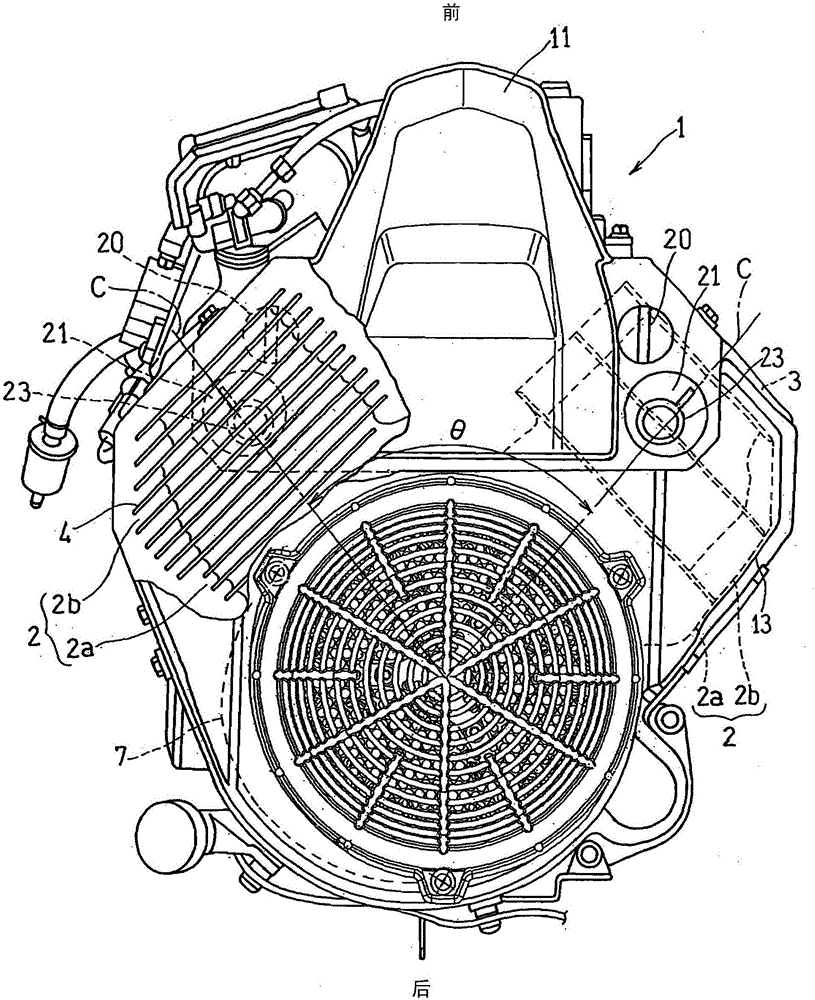

[0039] If according to image 3 As can be clearly seen, the engine 1 is a V-shaped two-cylinder engine in which a pair of cylinder units 2 , left and right, including a cylinder 2 a and a cylinder head 2 b are arranged in a V shape. The angle θ formed by the cylinder axes C and C of the cylinder units 2 and 2 is 70 to 90°, and is 80° in this example. The tops of these cylinder units 2, 2 are respectively made of figure 1 The cylinder head cover 3,3 covers. A plurality of cooling fins 4 are formed on the outer periphery of each cylinder unit 2 .

[0040] Between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com