A long-span highway anti-glare isolation net

A technology of isolation net and span, applied in protective equipment, buildings, etc., can solve the problems of easy sagging of anti-glare isolation net, lengthened interval distance, etc., and achieve the effect of convenient and fast installation, maintenance and replacement, increase structural strength, and light and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

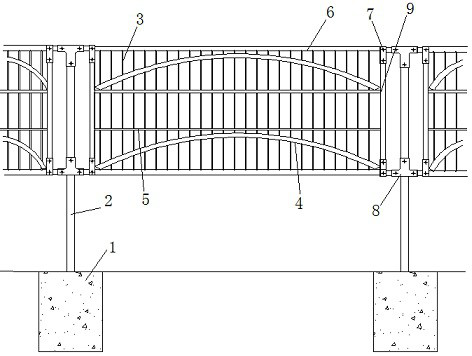

[0049] like figure 1 As shown, this embodiment provides a long-span highway anti-glare isolation net, including an isolation grille arranged between two adjacent columns 2, and the isolation grille is mainly composed of a frame and a number of vertical bars arranged in the frame. The spacer bar 3 is constituted. The frame includes an upper horizontal bar 6 , a lower horizontal bar and two left and right vertical bars 9 . At least one of the upper cross bar 6 or the lower cross bar of the isolation grille is arched, or when both the upper cross bar 6 and the lower cross bar are straight, at least one of the upper cross bar 6 and the lower cross bar is arranged. An arched rib 4. The arched rib is straight in the free state, or has less curvature than after wearing the spacer bar. The spacer bar 3 and the ribs, the upper crossbar 6 and the lower crossbar are in an interpenetrating structure, the ribs, the upper crossbar 6 and the lower crossbar are provided with holes, and the...

Embodiment 2

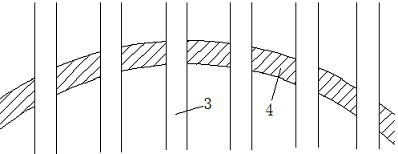

[0054] like Figure 4 As shown in the figure, the long-span highway anti-glare isolation net provided by this embodiment is exactly the same as that of Embodiment 1 in terms of the structure of the column, the frame and the isolation rod, and the connection method between the various components, the difference is :

[0055] This embodiment includes a straight rib 5 and two arched ribs 4 , and the two arched ribs 4 are located above and below the straight rib 5 respectively. The curved shape of the upper arched rib 4 is downward bending, and the curved shape of the lower arched rib 4 is upward arch.

Embodiment 3

[0057] like Figure 5 As shown in the figure, the long-span highway anti-glare isolation net provided by this embodiment is exactly the same as that of Embodiment 1 in terms of the structure of the column, the frame and the isolation rod, and the connection method between the various components, the difference is :

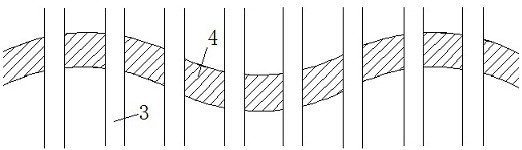

[0058] This embodiment includes a straight rib 5 and an arched rib 4 , and the arched rib is located above the straight rib 5 . The curved shape of the arched rib 4 is wavy. like figure 2 Shown is a sectional view of the spacer rod 3 passing through the hole of the corrugated rib 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com