Corridor support system for helipad

A support system and apron technology, applied to helicopter landing pads, buildings, etc., can solve problems such as safety hazards in the support system of helipad corridors, corrosion and cracks in welding parts, and increased assembly costs, etc., to achieve strong market promotion value , shorten the assembly period, the effect of simple and fast assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

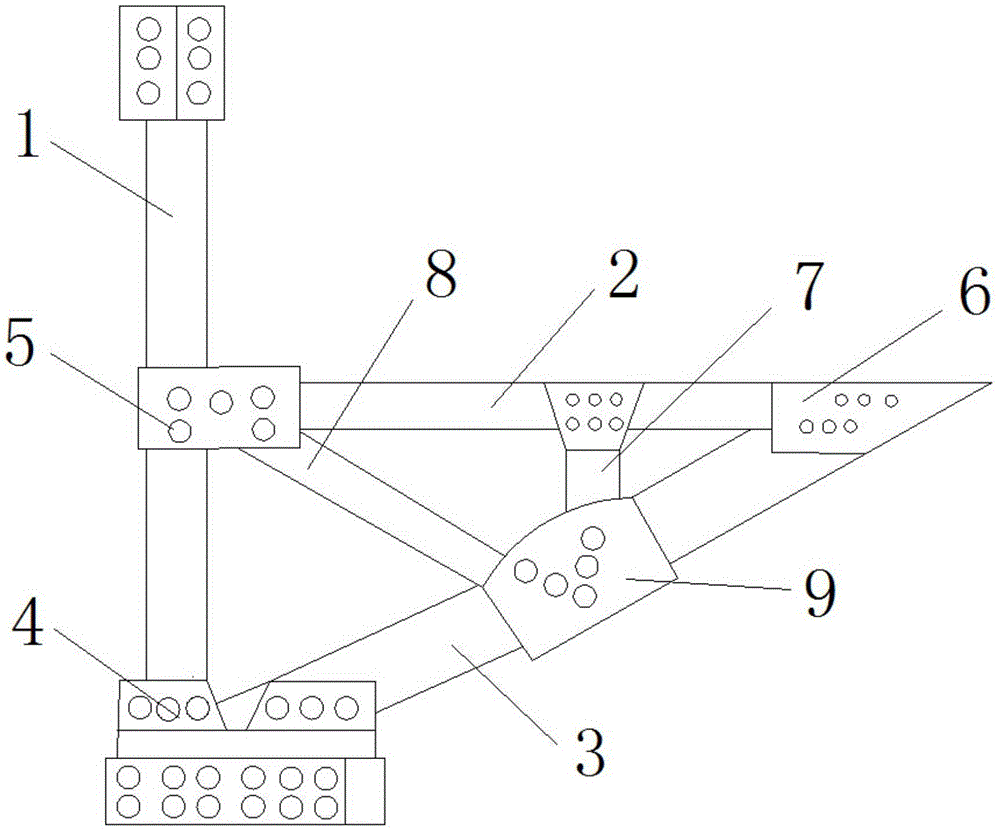

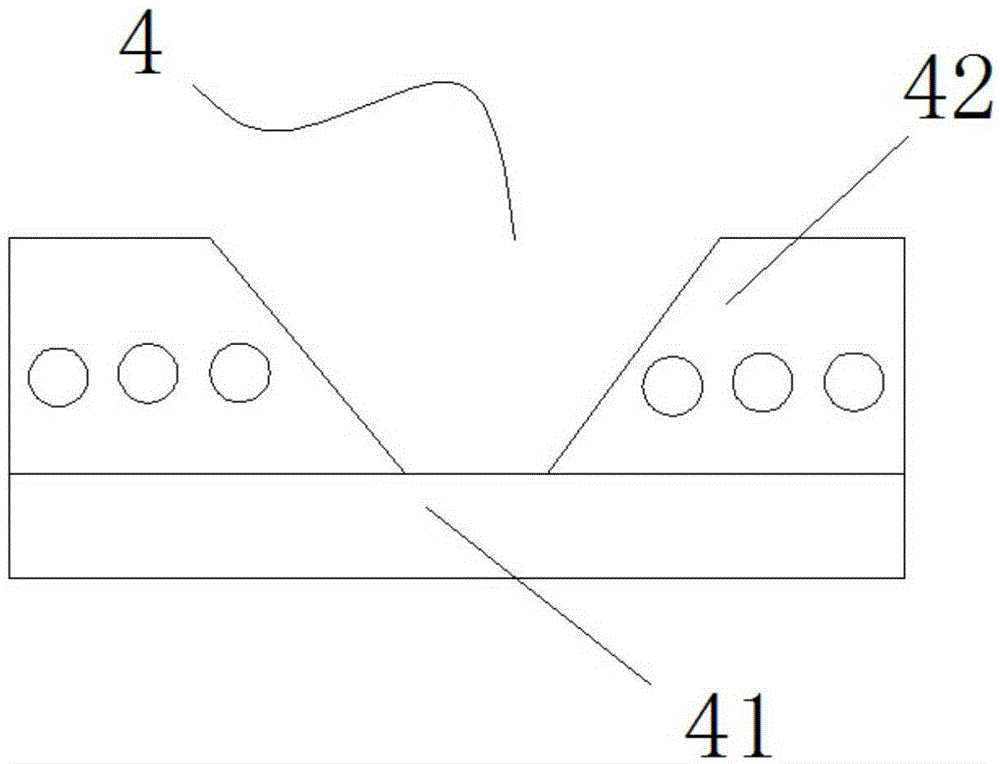

[0016] see figure 1 and figure 2 . figure 1 It is a structural schematic diagram of the helipad corridor support system of the present invention. figure 2 is a schematic diagram of the reinforcement device. The helipad corridor support system of the present invention comprises a plurality of apron support frames 1, a plurality of corridor support trusses 2 and corridor diagonal braces 3, the corridor support trusses 2 are fixed on the apron support frame 1, and the corridor diagonal braces 3 One end of the apron support frame 1 is fixedly connected by a reinforcement device 4 at the lower end of the apron support frame 1, and the other end of the corridor diagonal brace 3 is fixed on the corridor support truss 2.

[0017] In this embodiment, the corridor support truss 2 is preferably vertically fixed on the apron support frame 1 through a mounting seat 5, and the corridor diagonal brace 3 is fixed on the corridor support truss 2 through a diagonal brace 6, and the adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com