Double-end rear cotton removing system based on itinerant cleaning technology

A clean technology, double-ended technology, applied in textiles and papermaking, etc., can solve problems such as difficult cleaning, low efficiency of waste cotton, waste cotton jammed pulleys, etc., to save energy, speed up cleaning, and avoid redundant accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

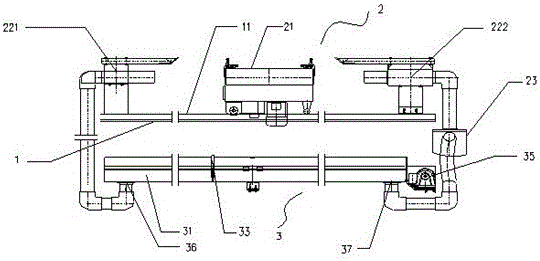

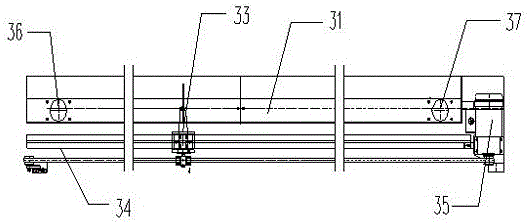

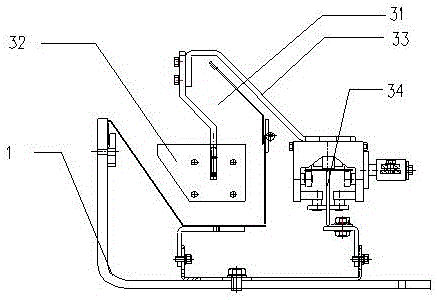

[0027] Such as figure 1 Shown is a double-end rear cotton removal system based on roving cleaning technology, including a frame, the frame 1 is provided with a roller drafting area along its length direction, and the top of the frame 1 is provided with a guide rail 11 of a roving cleaning mechanism ;Including tour cleaning mechanism 2, rear cotton collection mechanism 3;

[0028] The itinerant cleaning structure comprises a cleaning machine 21, a cotton suction seat 22 and a waste cotton box 23; The top of the frame 1 reciprocates; the waste cotton box 23 is placed on the side of the frame 1; the cotton suction seat 22 includes a cotton suction seat A221 and a cotton suction seat B222, and the cotton suction seat A221 and the cotton suction seat B222 are fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com