A purification device and method for molten salt

A purification device and molten salt technology, which is applied in the field of molten salt device purification, can solve the problems of polluting electrolytic titanium and increasing the content of titanium oxygen, and achieve the effect of high purification purity and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

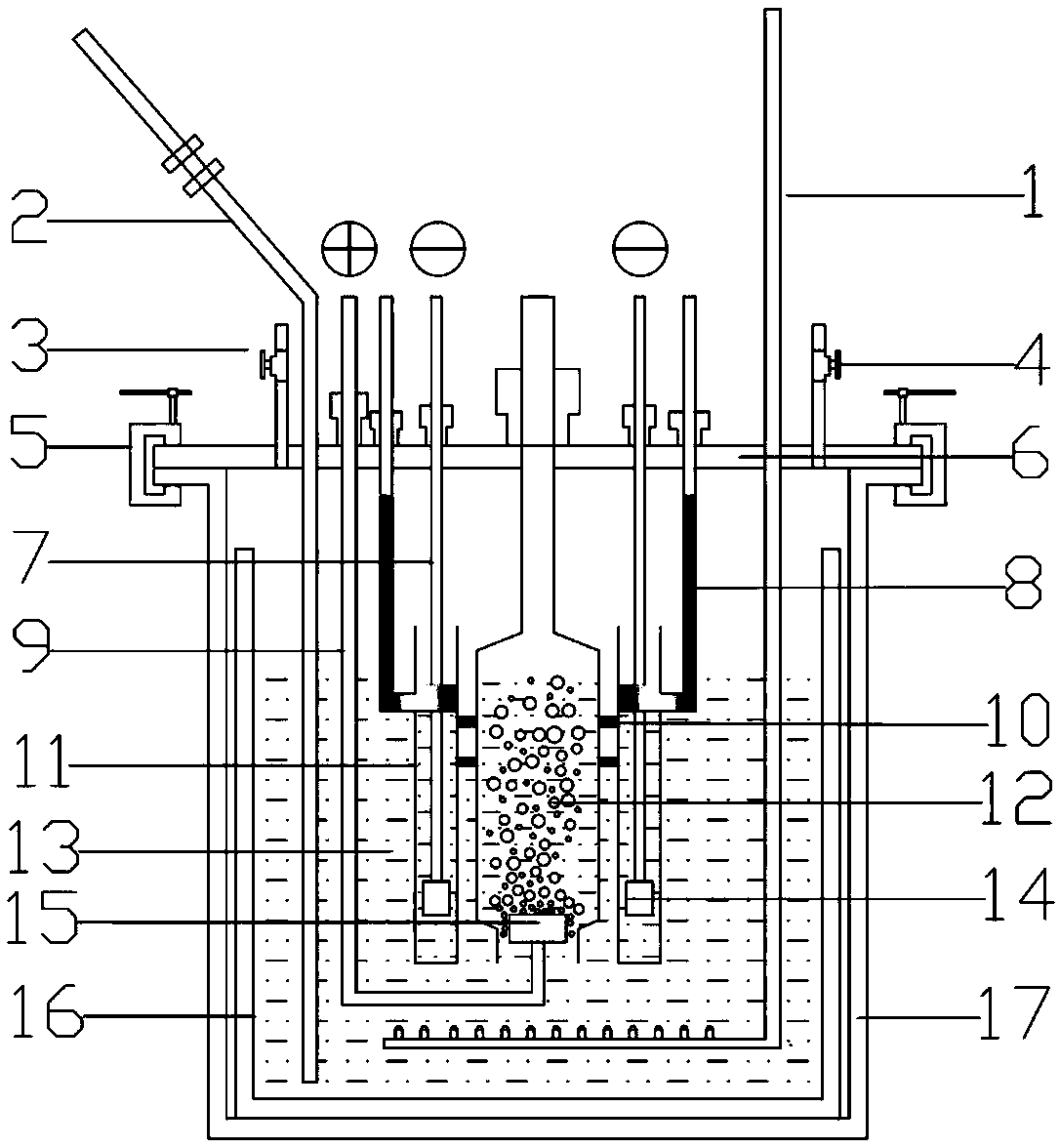

[0075] 1. Under airtight conditions, open the vacuum valve of the inert gas / vacuum tube 3 to evacuate until the absolute pressure in the reactor 17 is 50 Pa. After maintaining for 30 minutes, close the vacuum valve of the inert gas / vacuum tube 3 and open the inert gas / vacuum tube 3 Fill the gas valve with argon gas, repeat 2 times, and complete the gas washing.

[0076] 2. Continue to fill with argon until the pressure in the reactor 17 is maintained at a positive pressure of 300 Pa. After heating to 800° C., the NaCl molten salt is introduced into the crucible 16 along the molten salt conduit 2 .

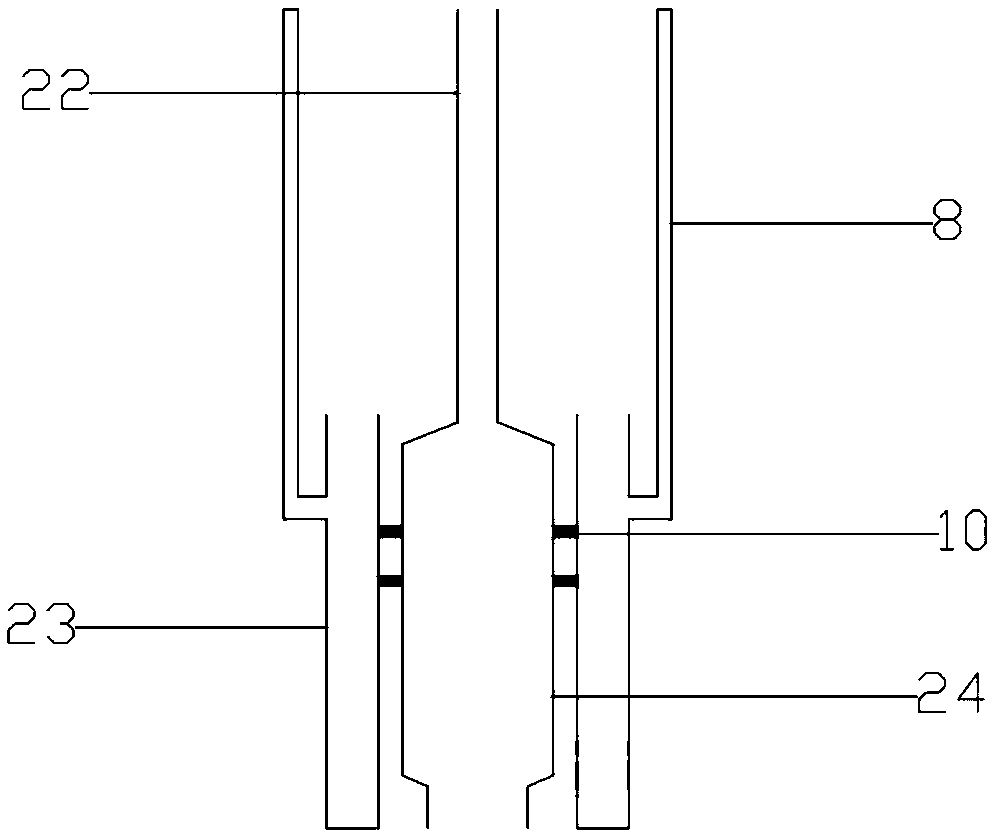

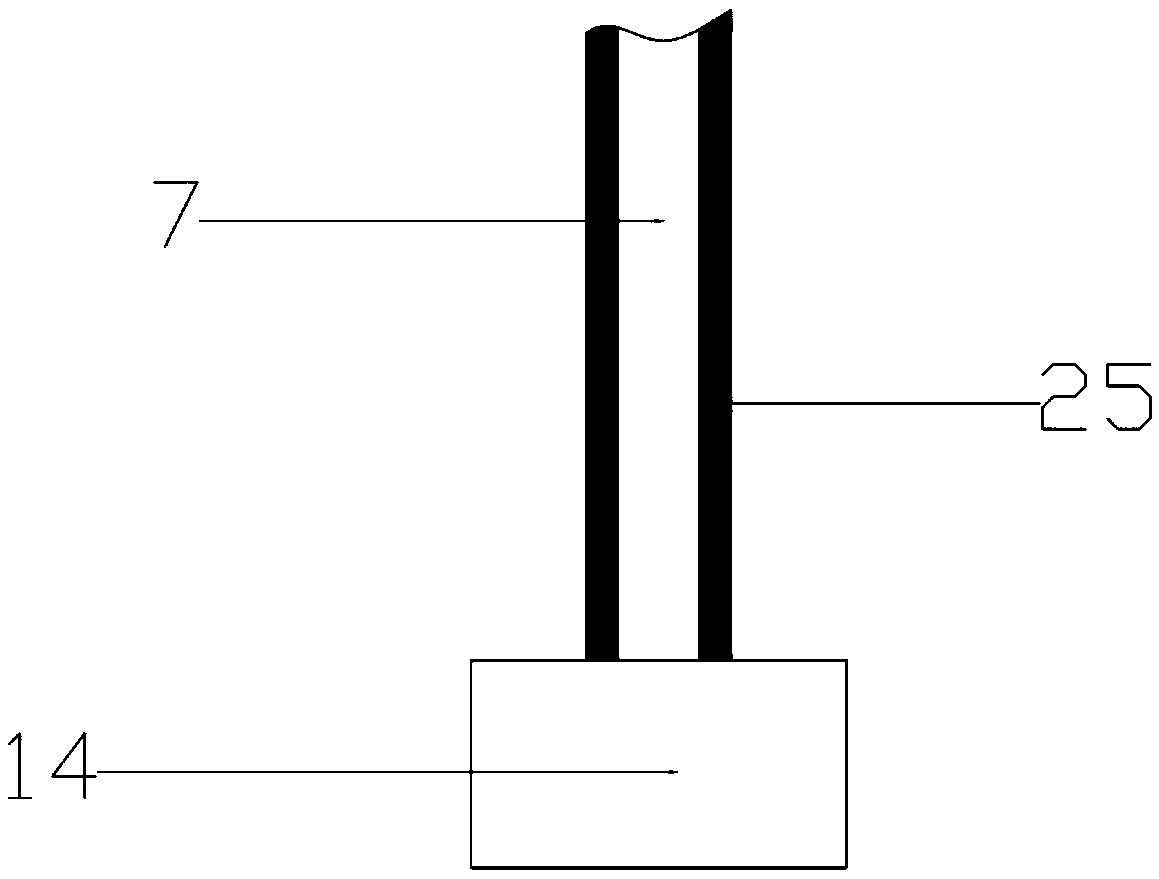

[0077] 3. Connect the cathode compartment 23 and the anode compartment 24 of the electrode compartment 11 to the positive and negative poles of the external power supply through the cathode guide rod 7 and the anode guide rod 9 respectively, feed in a 5A direct current, and perform electrolysis for 4 hours.

[0078] For every 50 minutes of electrification, argon gas was introduced ...

Embodiment 2

[0082] This embodiment is basically the same as Embodiment 1, the difference is:

[0083] 1. The absolute pressure in the reactor 17 is 100 Pa during the scrubbing process, and it is maintained for 40 minutes, and repeated 3 times.

[0084] 2. The molten salt is KCl, and the positive pressure of the molten salt in the reactor 17 is 800 Pa, and the temperature is 750°C.

[0085] 3. The current is 10A DC, and the gas is stirred for 15 minutes every 70 minutes.

[0086] The purified molten salt electrolyte was analyzed for purity, and the purity reached 99.985%, and the oxygen content was 70ppm.

Embodiment 3

[0088] This embodiment is basically the same as Embodiment 1, the difference is:

[0089] 1. The absolute pressure in the reactor 17 is 30 Pa during the scrubbing process, and it is maintained for 30 minutes, and repeated 5 times.

[0090] 2. The molten salt is NaCl-KCl, and the positive pressure of the molten salt in the reactor 17 is 600 Pa, and the temperature is 780°C.

[0091] 3. The current is 7A direct current, and the gas is stirred for 10 minutes every 60 minutes of electricity.

[0092] The purified molten salt electrolyte was analyzed for purity, and the purity reached 99.995%, and the oxygen content was 40ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com