Elastic clamping device

A clamping device and elastic technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of film stability decline, substrate size change, etc., and achieve easy processing, simple loading and unloading, and cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

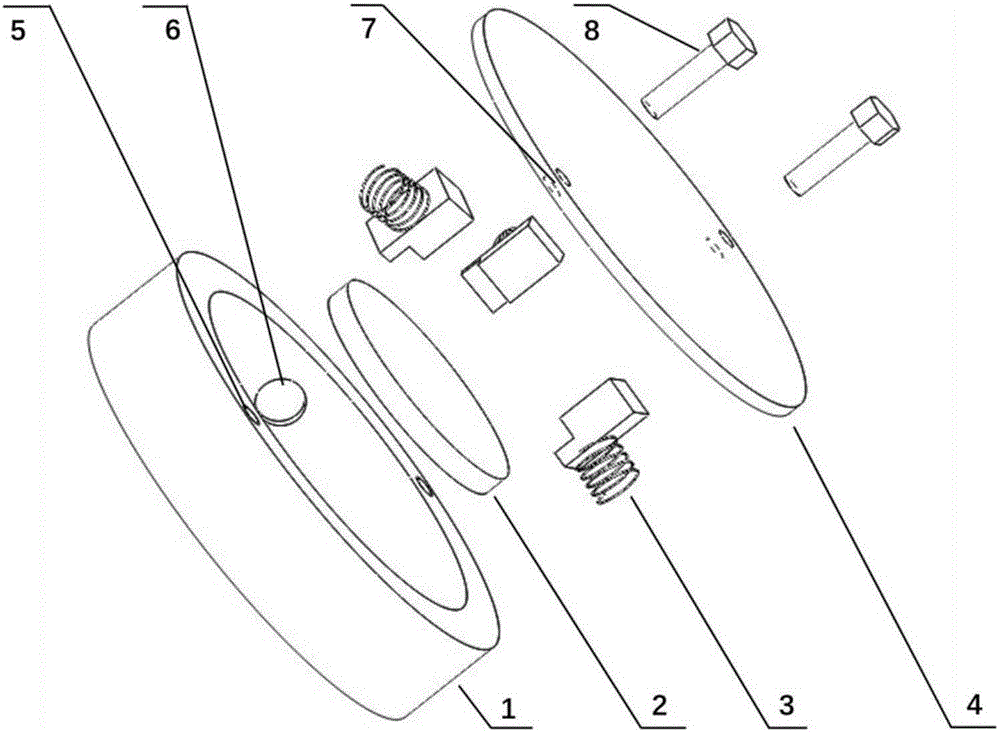

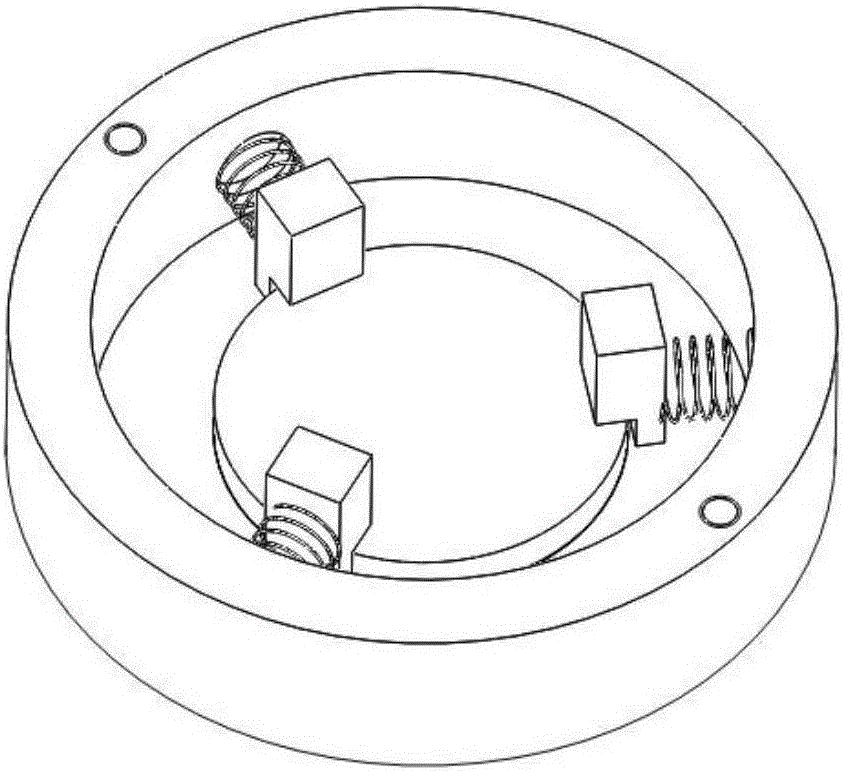

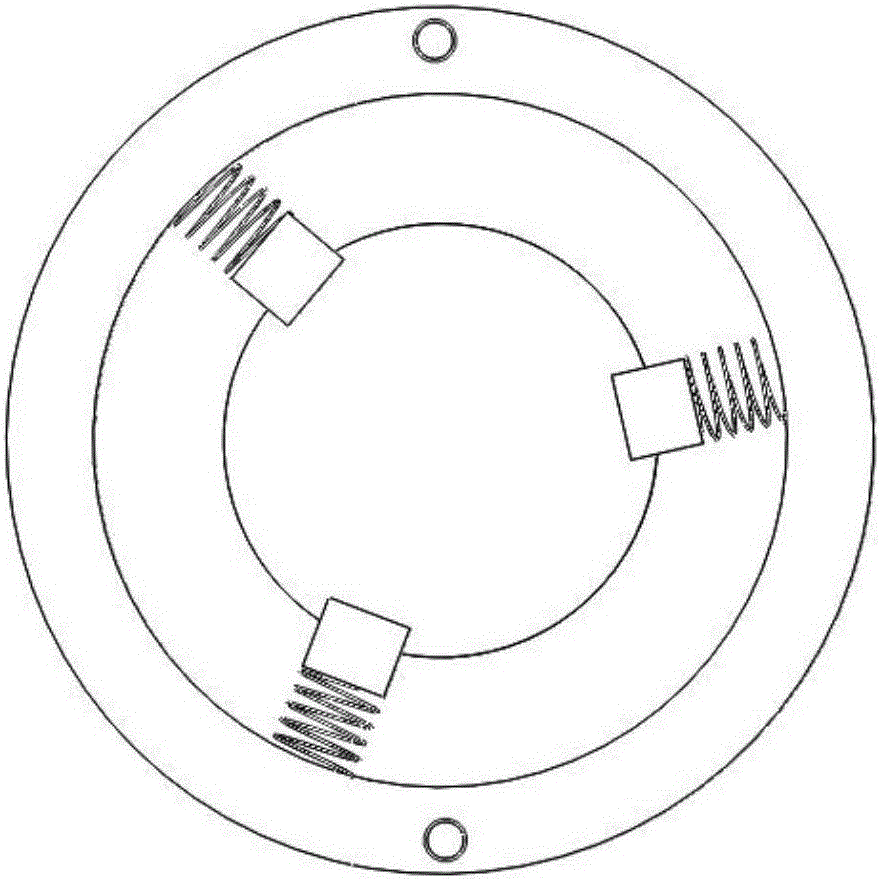

[0017] see first figure 1 , figure 1 It is an exploded view of an embodiment of the elastic clamping device of the present invention. It can be seen from the figure that the elastic clamping device used for fixing the substrate in the coating of the present invention includes a substrate clamp 1, a plurality of elastic fixing blocks 3, a cover plate 4 and bolts 8, and the substrate clamp 1 is a round cup shaped cavity, the center of the bottom of the cavity is a coating hole 9, three spring holes 6 are evenly distributed on the inner wall of the cavity, and two screw holes 5 are arranged on the upper end surface of the cavity wall. The elastic fixing block 3 It is composed of a spring and a fixed block transversely welded. The fixed block is square. The lower end surface of the fixed block has a gap that fits with the substrate to be coated. The elastic fixed block 3 is placed on the said fixed block by a spring. In the spring hole 6 of the inner wall of the substrate holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com