A Control Method of Suction and Release Plate Based on DC Electromagnet

A DC electromagnet and board control technology, applied in the field of power electronics, can solve the problems of high cost, large size of electric control cabinet, complicated circuit, etc., and achieve the effect of cost reduction, high control precision and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

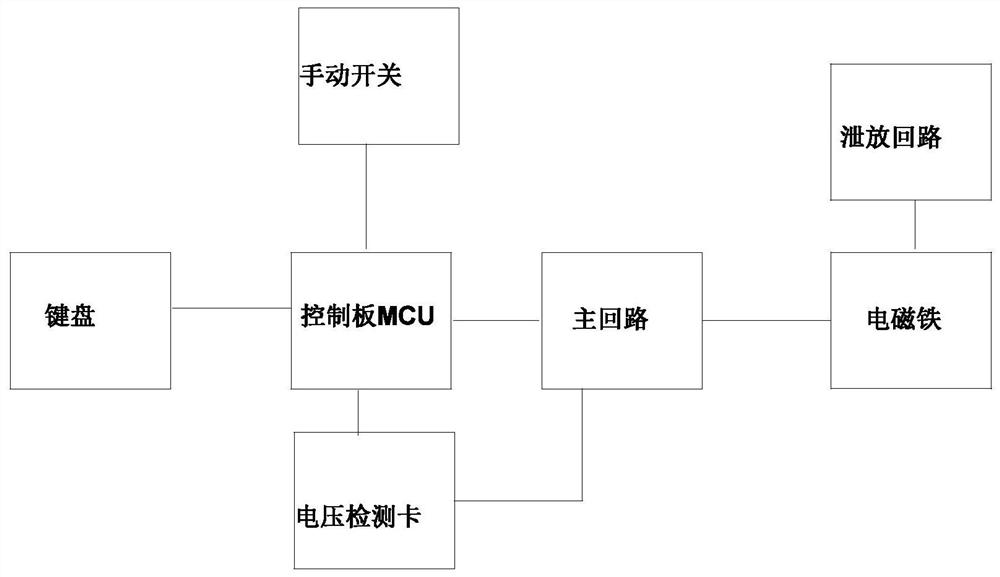

[0085] Embodiment 1: as Figure 1~5 , a method for controlling the suction and release plate based on DC electromagnets, adopting the control system of the suction and release plate, the control system of the suction and release plate includes a control device 1, a crane 2, a hook 3 and an electromagnet (4);

[0086] The hook is arranged on the driving; the electromagnet is arranged on the hook, and is used for sucking and releasing the steel plate 5;

[0087] The excitation and demagnetization of the electromagnet are controlled by the control device;

[0088] The control device includes a main circuit, a control circuit and a discharge circuit;

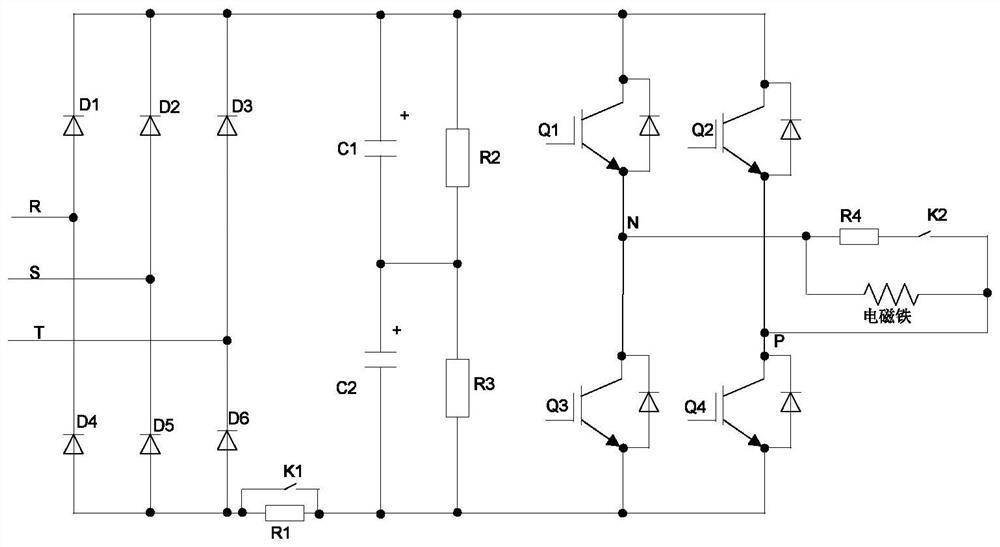

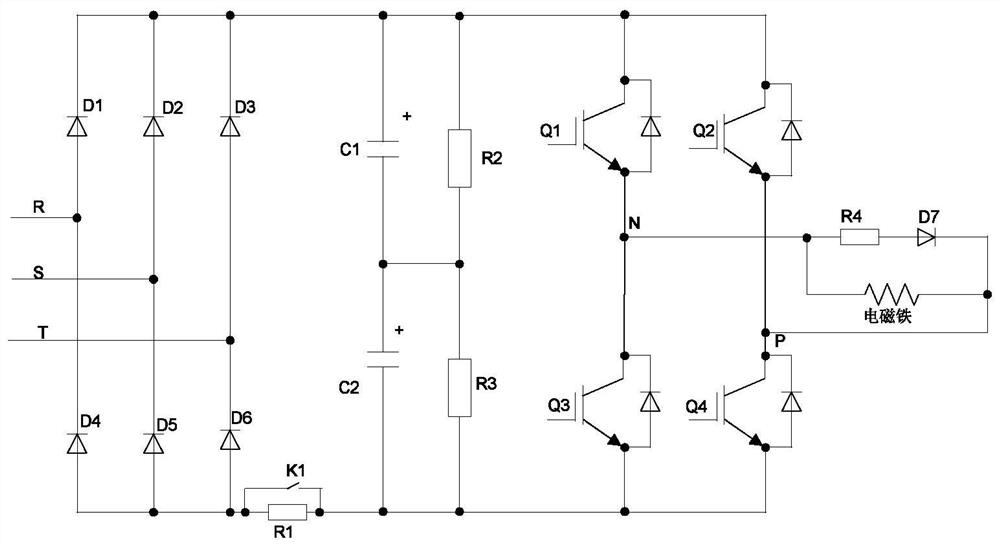

[0089] The main circuit includes a three-phase uncontrollable rectifier bridge, an energy storage capacitor branch, a voltage equalizing resistor branch and an H-bridge inverter;

[0090] The three-phase uncontrolled rectifier bridge is a rectifier bridge composed of 6 diodes;

[0091] The H-bridge inverter is a 2-bridge arm modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com