A pvc louver automatic printing machine and its working method

A technology of louver and printing machine, which is applied in the direction of thin material processing, object separation, transportation and packaging, etc. It can solve the problems of difficult selection and removal of PVC louver, failure to guarantee PVC louver, scrapping of PVC louver, etc., and achieve quality Lightweight, improved labor efficiency, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

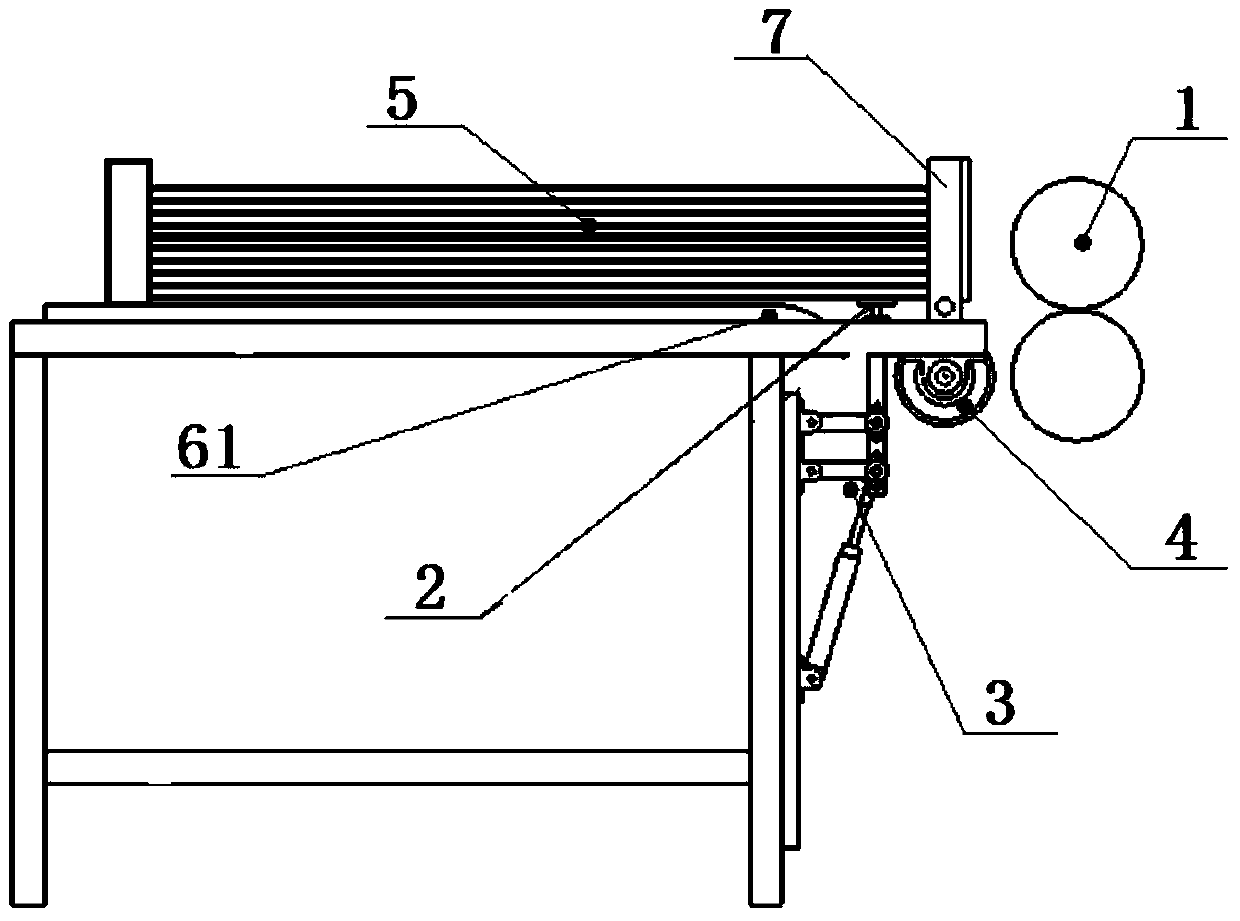

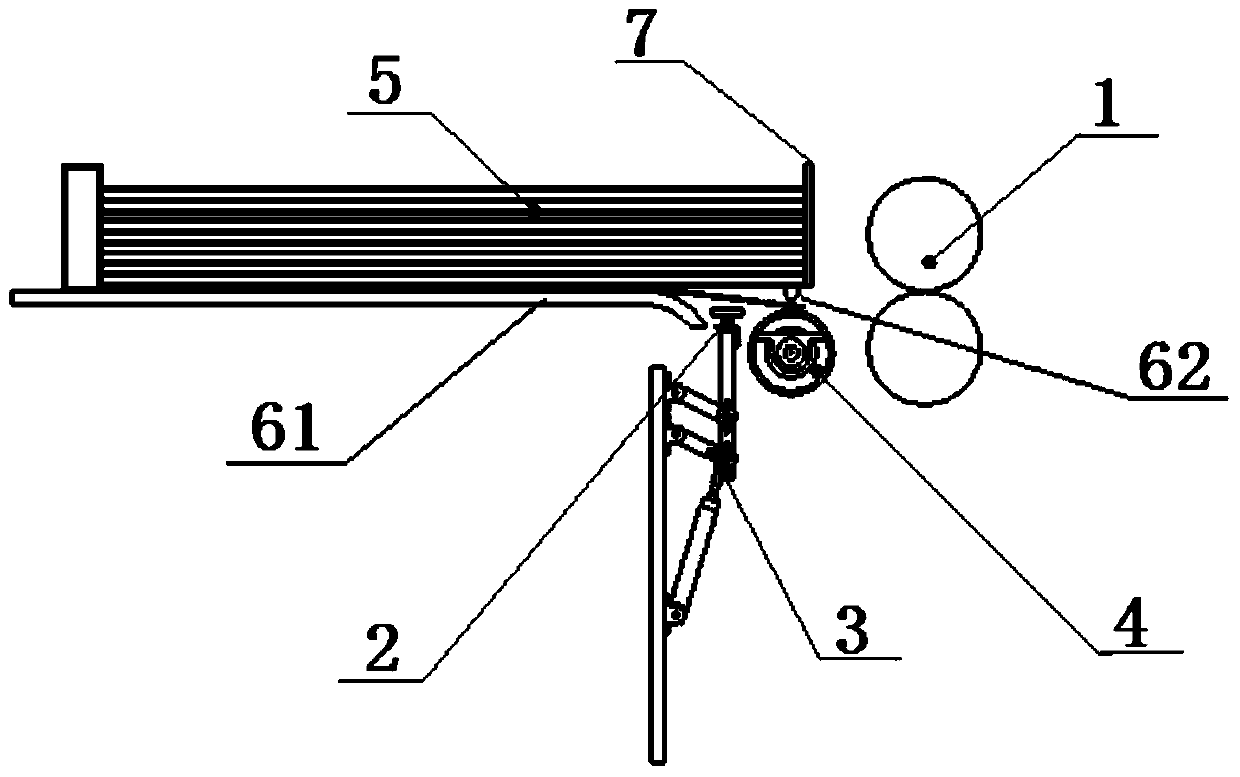

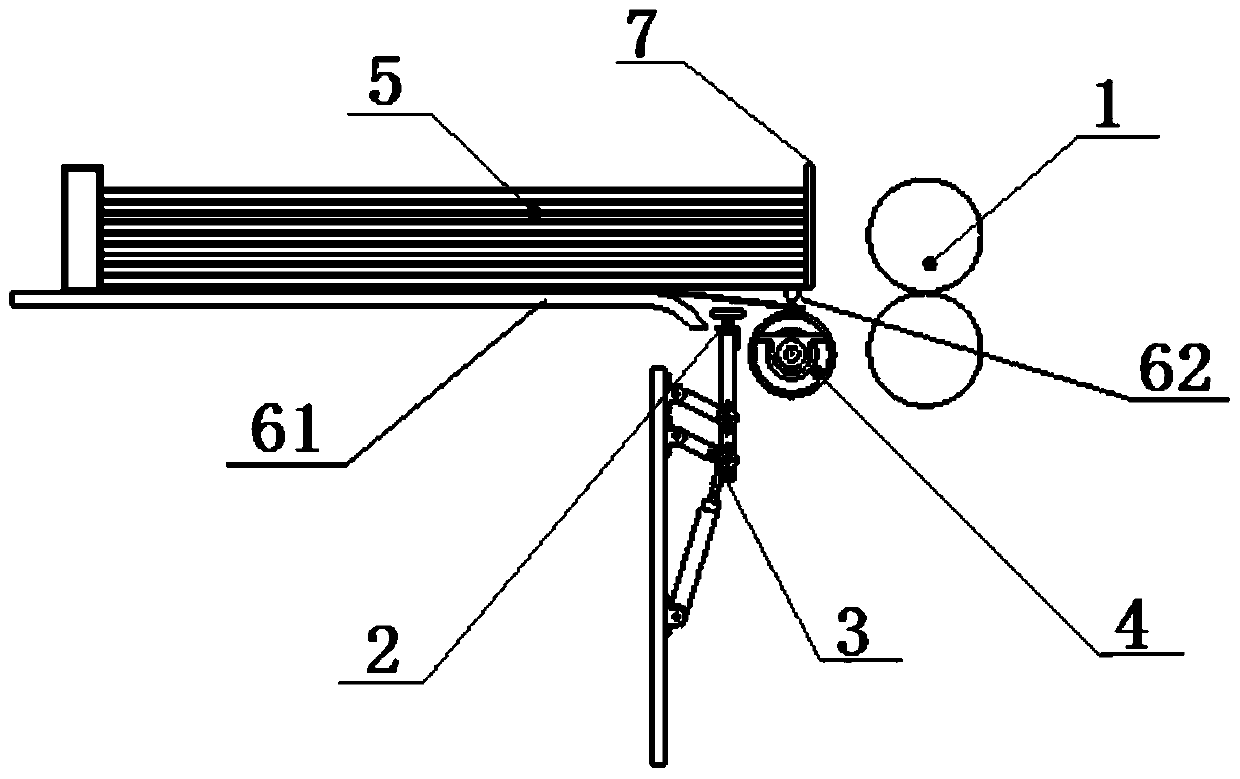

[0025] Example 1 as Figure 1-Figure 2 As shown, the PVC louver automatic printing machine of this embodiment includes a support pallet 61 as a first support mechanism, a freely rotatable support roller 62 as a second support mechanism, a plurality of vacuum suction cups 2 arranged side by side, Vacuum suction cup moving mechanism 3 and sheet-feeding mechanism, support pallet 61 and support idler 62 are arranged adjacent to and leave gap between the two, and support pallet 61 is arranged as front end in arc shape near one end of support idler 62, to The bottom is bent; the vacuum suction cup 2 is arranged below the gap between the support pallet 61 and the support roller 62, the sheet feeding mechanism is a double-roller clamping type, the support roller 61 is used as the upper roller of the sheet feeding mechanism, and the servo motor is connected The driving roller 4 is set as the lower roller under the support roller 62, and there is a gap between the upper roller and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com