Roller way suitable for equipment movement

A technology of equipment and roller table, applied in the field of roller table with large stroke equipment, can solve the problems of complex control, error-prone, complex structure, etc., and achieve the effect of simple control, simple structure and large stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

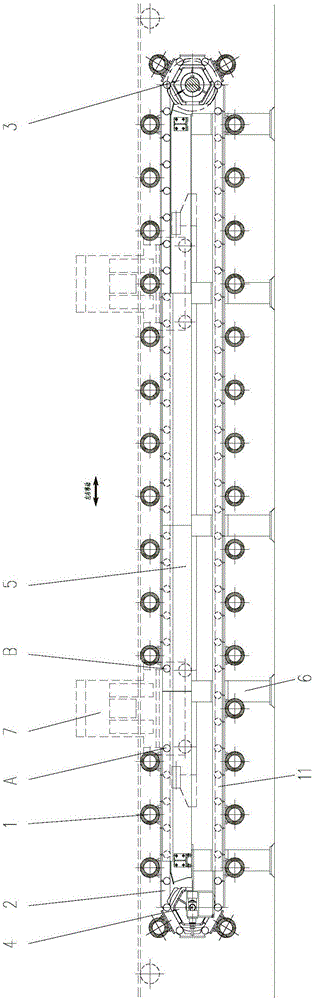

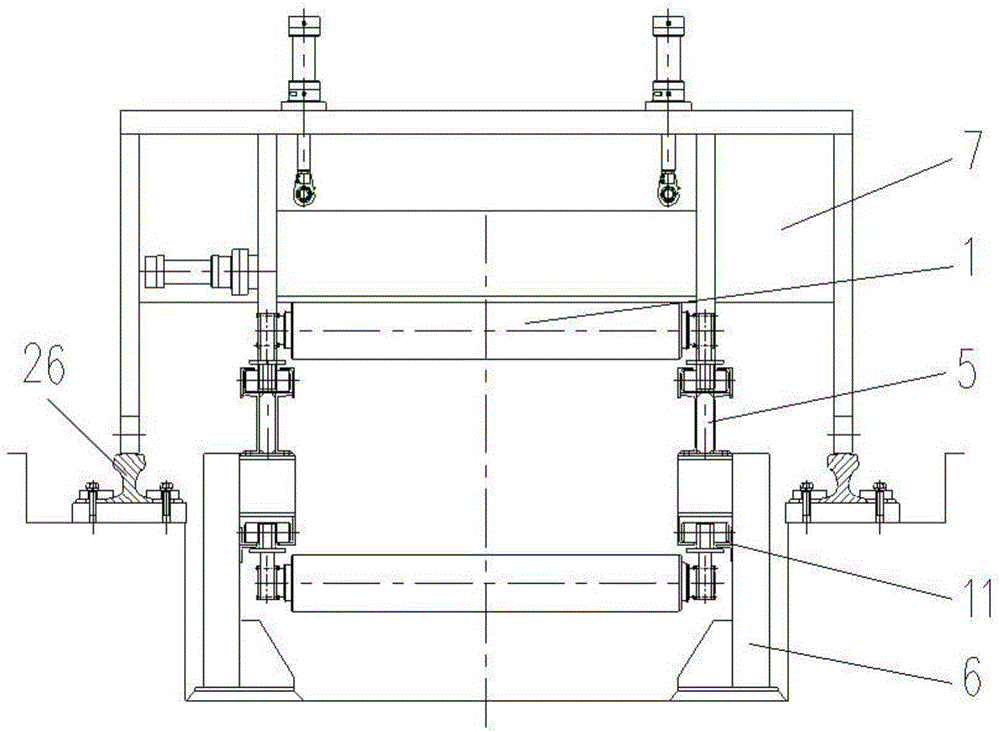

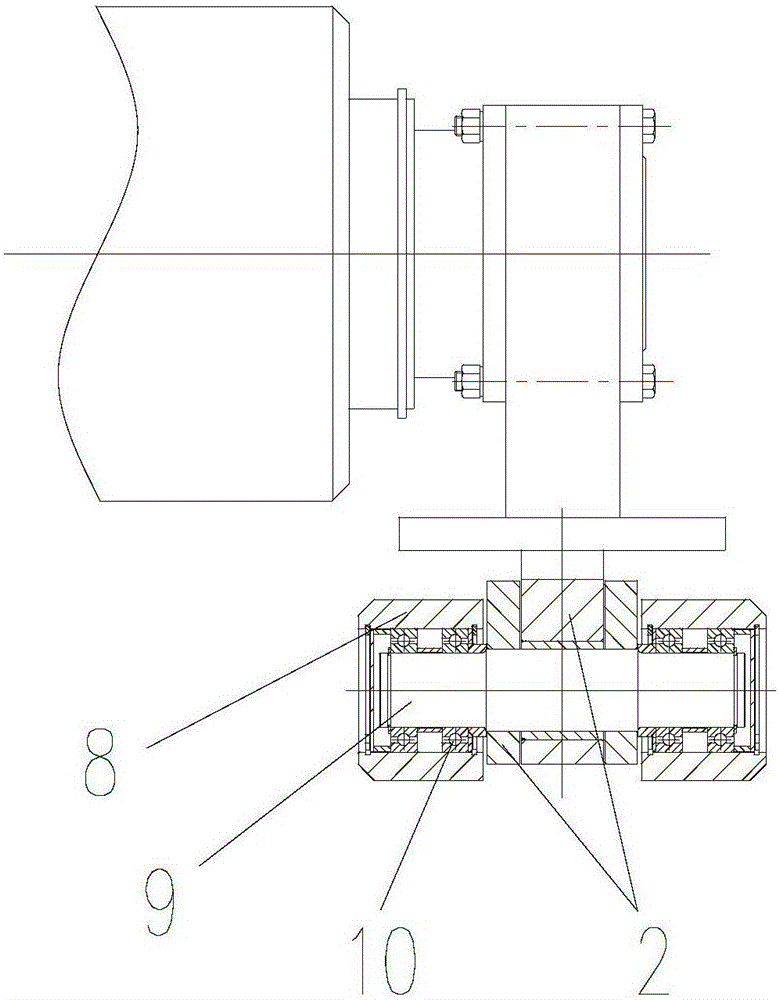

[0053] like figure 1 and figure 2 As shown, a roller table suitable for equipment movement includes a support mechanism 6, a transmission mechanism 3, a guide mechanism 5, a chain 2 and a roller 1. The roller 1 is an idler roller installed on the chain 2. The equipment 7 and the chain 2 in series to form a closed loop, the chain 2 is supported on the guide mechanism 5, and the transmission mechanism 3 drives the chain 2 to move, so as to reciprocate along the rolling direction with the equipment 7, the guide mechanism 5 is installed on the support mechanism 6, and the support mechanism 6 is fixed on The basis can be for brackets etc. The supporting mechanism 6 and the guiding mechanism 5 are arranged in two groups side by side on the operation side and the driving side, and the two chains 2 are installed on the guiding mechanism 5 correspondingly, and the two ends of the roller 1 are erected on the two chains 2 .

[0054] Because the equipment 7 is relatively huge and heavy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com