Automatic filling and shaking-up device for plate culture medium

A flat culture medium and automatic filling technology, applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of large machine structure and high cost, achieve neat wall-mounted interface, high production efficiency, and reduce the probability of condensation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

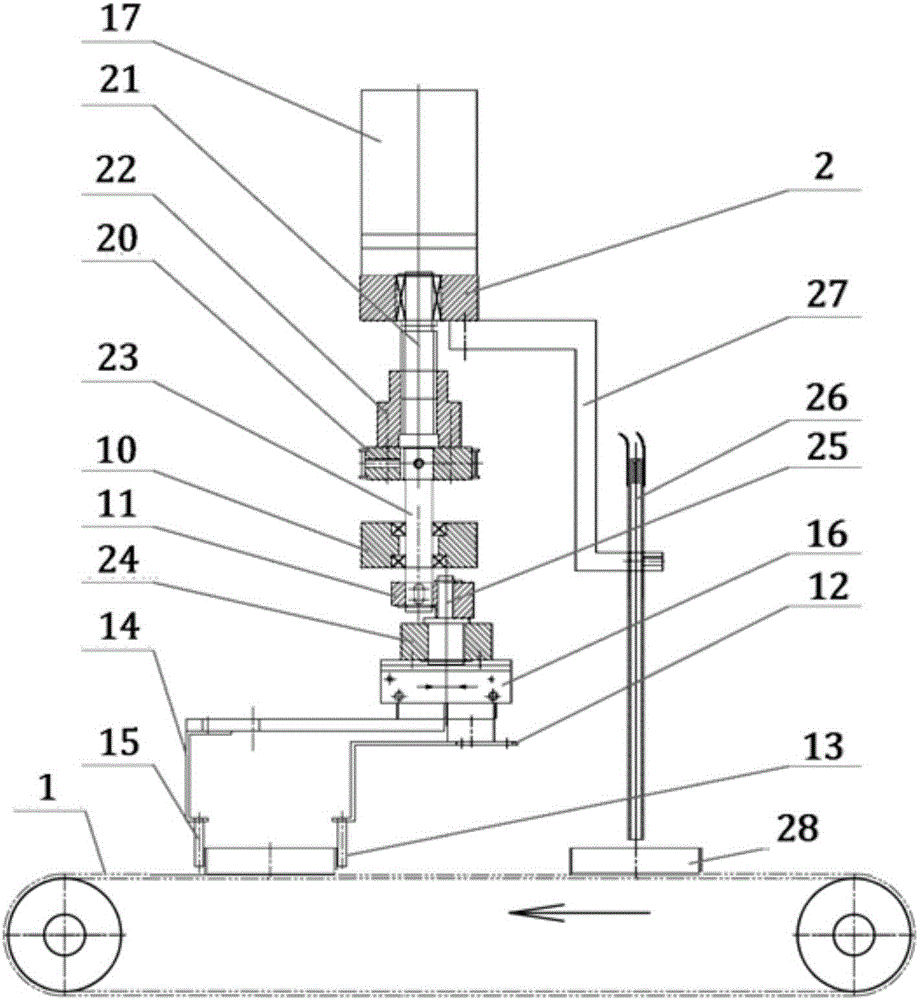

[0024] Such as figure 1 , figure 2 and image 3 As shown, the present embodiment includes: main conveyor belt 1, door-shaped main frame 2, first synchronous belt drive motor 8, lifting mechanism, dish shaking mechanism and filling head 26, wherein: main conveyor belt 1 is arranged on the main conveyor belt On the support frame 29, two first synchronous pulleys 5 are arranged on the left and right sides of the main conveyor belt support frame 29, and the two first synchronous pulleys 5 on the same side are connected by the first synchronous belt 4; the main conveyor belt support frame 29 is provided with a drive shaft 9, and the two ends of the drive shaft 9 are fixedly connected with two first synchronous pulleys 5 coaxial on different sides respectively; the first synchronous belt drive motor 8 is fixed on the main conveyor belt supporting frame 29, and the first The output end of the synchronous belt drive motor 8 is provided with a third synchronous pulley 7, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com