A vibration method for removing air bubbles in the production of prefabricated segments

A technology for segments and air bubbles, which is applied in the field of vibrating to remove air bubbles in the production of prefabricated segments, can solve the problems of excessive horizontal air bubbles, achieve the effects of less investment, improved molding quality, and easy promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

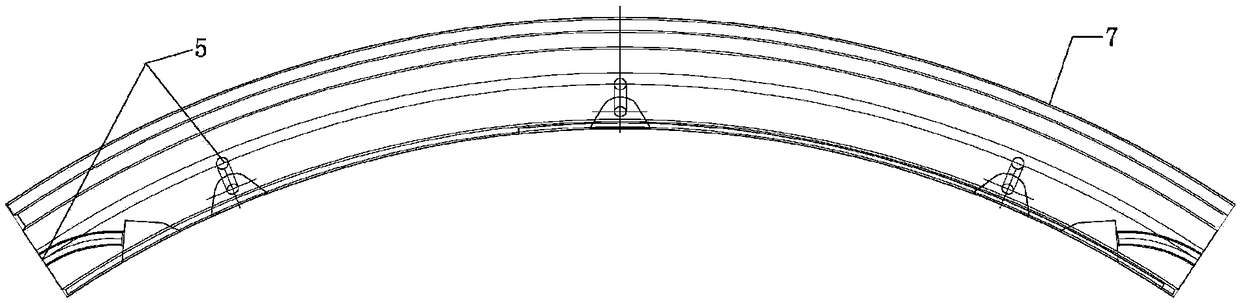

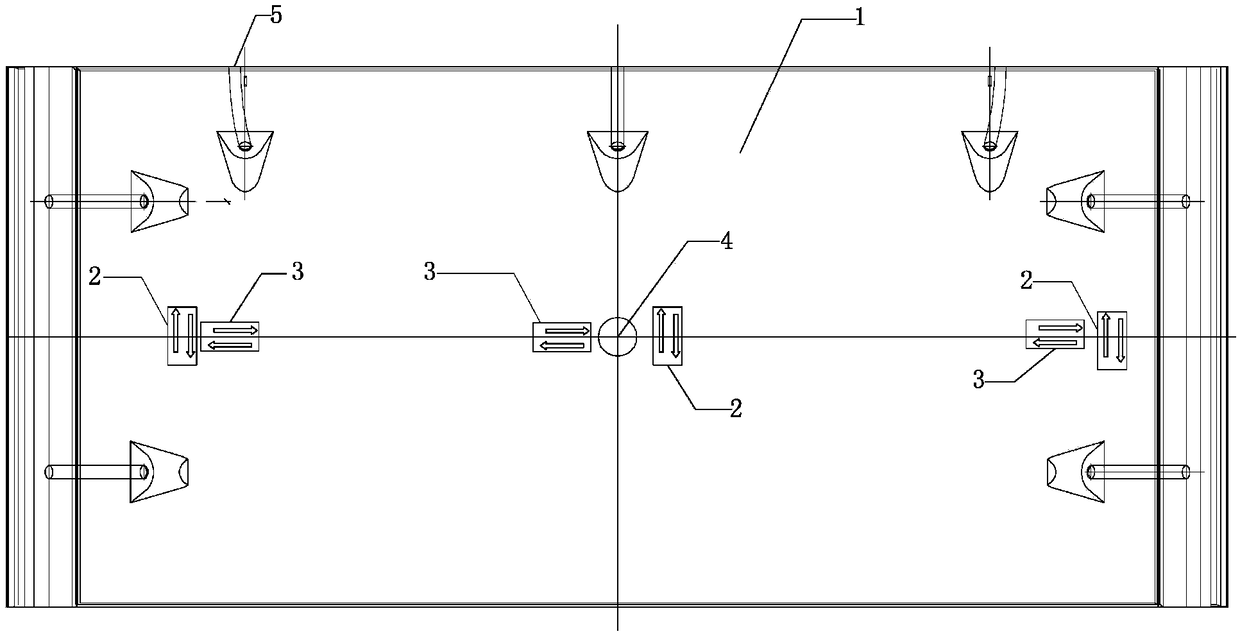

[0038] see figure 1 , figure 2 and image 3 , providing a vibration method for removing air bubbles in the production of prefabricated segments, which is carried out according to the following steps:

[0039] (1), no less than 6 attached vibrators are installed on the prefabricated segment mold. The prefabricated segment mold is made of die steel and consists of a bottom plate 1, four side plates 6, and two top plates 7. A special concrete prefabricated part mold for the production of tunnel segments, the attached vibrator consists of a longitudinal vibrator 2 and a transverse vibrator 3 as a group and is respectively fixed on the prefabricated segment mold bottom plate 1 by bolts Two edges and the middle part, wherein, the net distance between each group of two vibrators is 2cm, and the distance between the vibrator on the outermost side of the vibrator group at the edge of the mold is 20cm from the two longitudinal side plates 6 of the mould. The horizontal and vertical ...

Embodiment 2

[0044] see figure 1 , figure 2 and image 3 , providing a vibration method for removing air bubbles in the production of prefabricated segments, which is carried out according to the following steps:

[0045] (1), no less than 6 attached vibrators are installed on the prefabricated segment mold. The prefabricated segment mold is made of die steel and consists of a bottom plate 1, four side plates 6, and two top plates 7. A special concrete prefabricated part mold for the production of tunnel segments, the attached vibrator consists of a longitudinal vibrator 2 and a transverse vibrator 3 as a group and is respectively fixed on the prefabricated segment mold bottom plate 1 by bolts Two edges and the middle part, wherein, the net distance between each group of two vibrators is 2cm, and the distance between the vibrator on the outermost side of the vibrator group at the edge of the mold is 20cm from the two longitudinal side plates 6 of the mould. The horizontal and vertical ...

Embodiment 3

[0051] This embodiment is a preferred embodiment of Embodiment 1.

[0052] see figure 1 , figure 2 and image 3 , providing a vibration method for removing air bubbles in the production of prefabricated segments, which is carried out according to the following steps:

[0053] (1), 6 attached vibrators are installed on the prefabricated segment mold. The prefabricated segment mold is made of die steel, and is composed of a base plate 1, four side plates 6, and two top plates 7. It is a special concrete prefabricated part mold for the production of tunnel segments. The attached vibrator is divided into 3 groups and fixed on the two edges and the middle of the bottom plate 1 of the prefabricated segment mold by bolts, of which a longitudinal vibrator 2 and a transverse vibrator The vibrator 3 is 1 group, and the clear distance between each group of two vibrators is 2cm, and the distance between the vibrator on the outermost side of the vibrator group at the edge of the mold i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com