Gear slot batched cleaning device

A technology for cleaning devices and gear teeth, applied in the direction of gear teeth, belts/chains/gears, components with teeth, etc., can solve the problems of heavy workload, unfavorable mass production, and inconvenient personnel management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

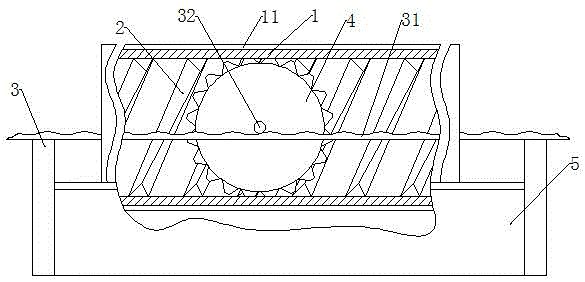

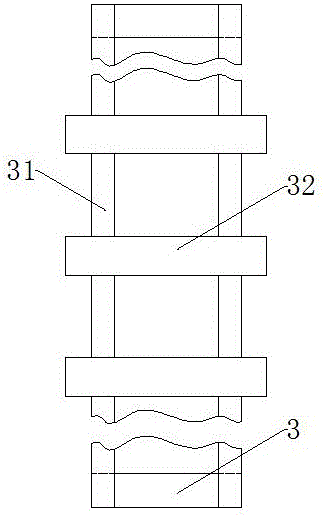

[0018] Embodiment 2, the difference between this embodiment and Embodiment 1 is that the outer wall of the drum 1 is coated with a rubber anti-slip layer, and the surface of the rubber anti-slip layer is provided with reticulated anti-slip lines, and the outer ring gear 11 is not provided, correspondingly The drive roller 52 and the driven roller are not connected with the drive ring gear. Realize the drive of cylinder 1 only by the friction of driving roller 52, driven roller and cylinder 1 surface like this, make flexible contact between cylinder 1 and driving roller 52 or driven roller, can reduce the rigid contact wear of cylinder 1 surface, simultaneously It has a certain buffering and anti-skid effect, can provide more stable driving, and makes the drum 1 more stable during rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com