FPC precision alignment machine

A kind of alignment machine and precision technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems of difficulty in meeting the diversified needs of customers, inability to guarantee high precision, and reduced flexibility, so as to solve the problems of low personnel efficiency, Good diversification of demand and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

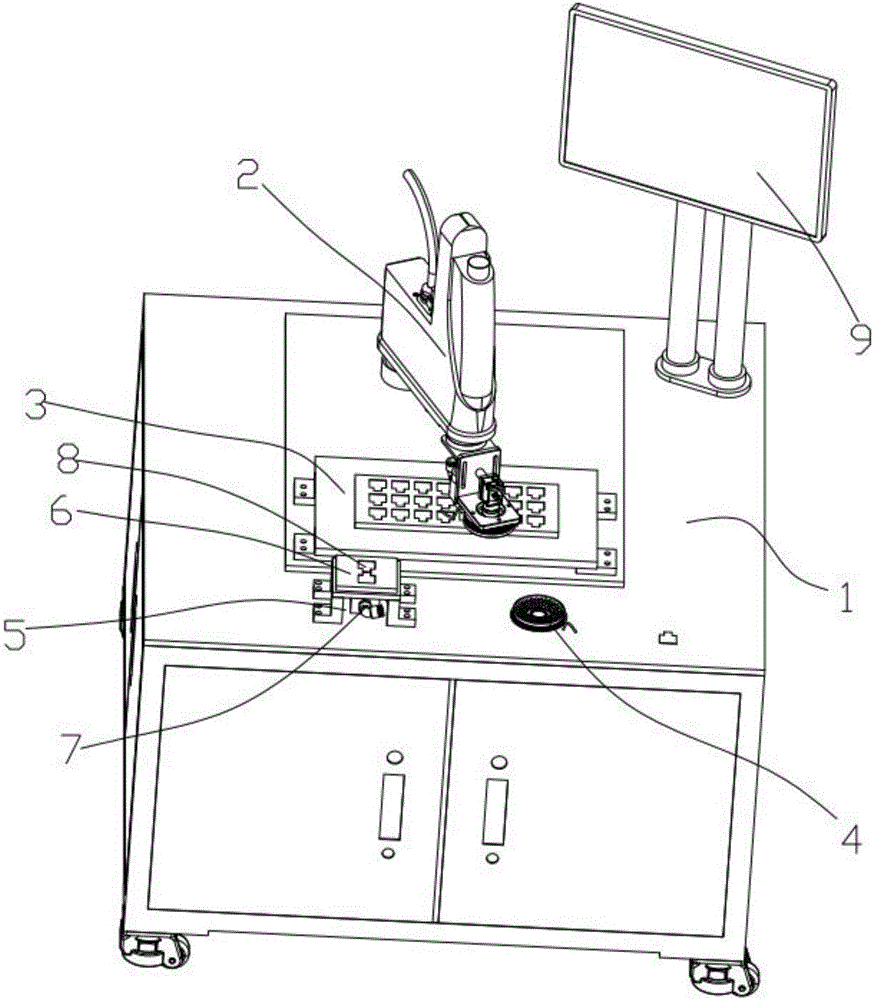

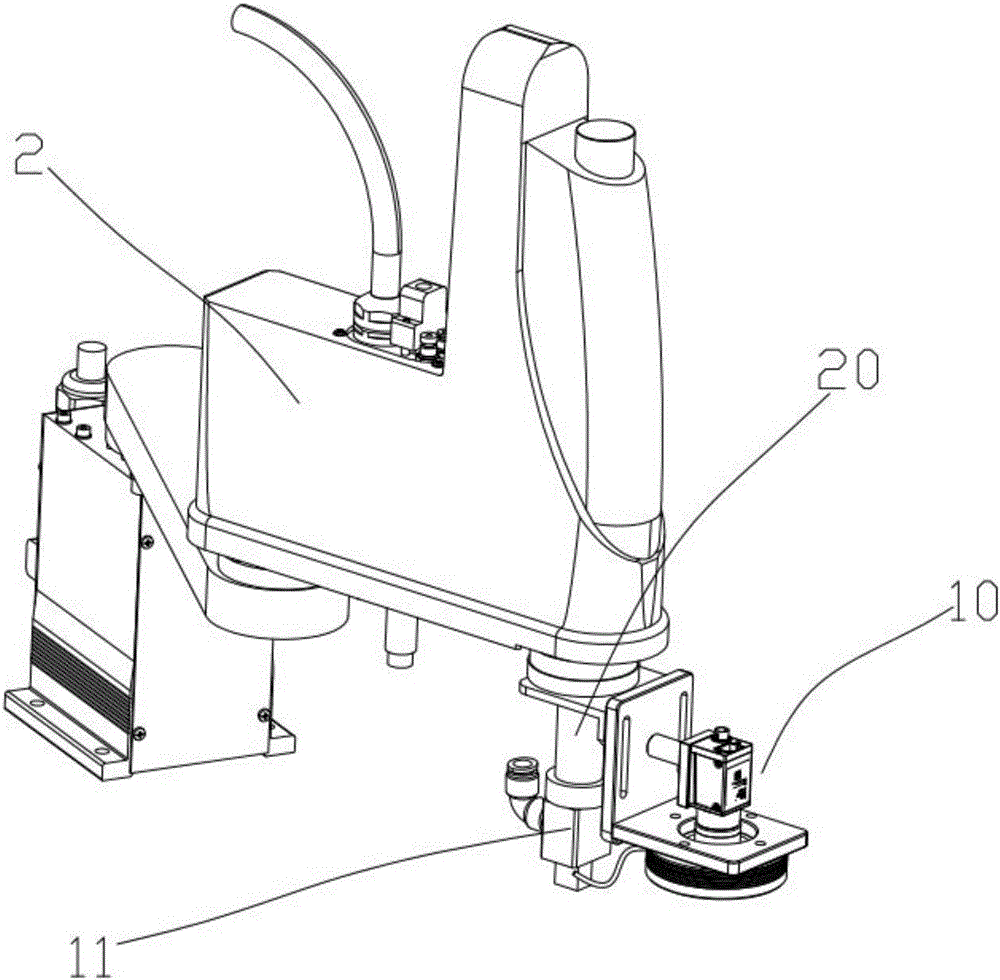

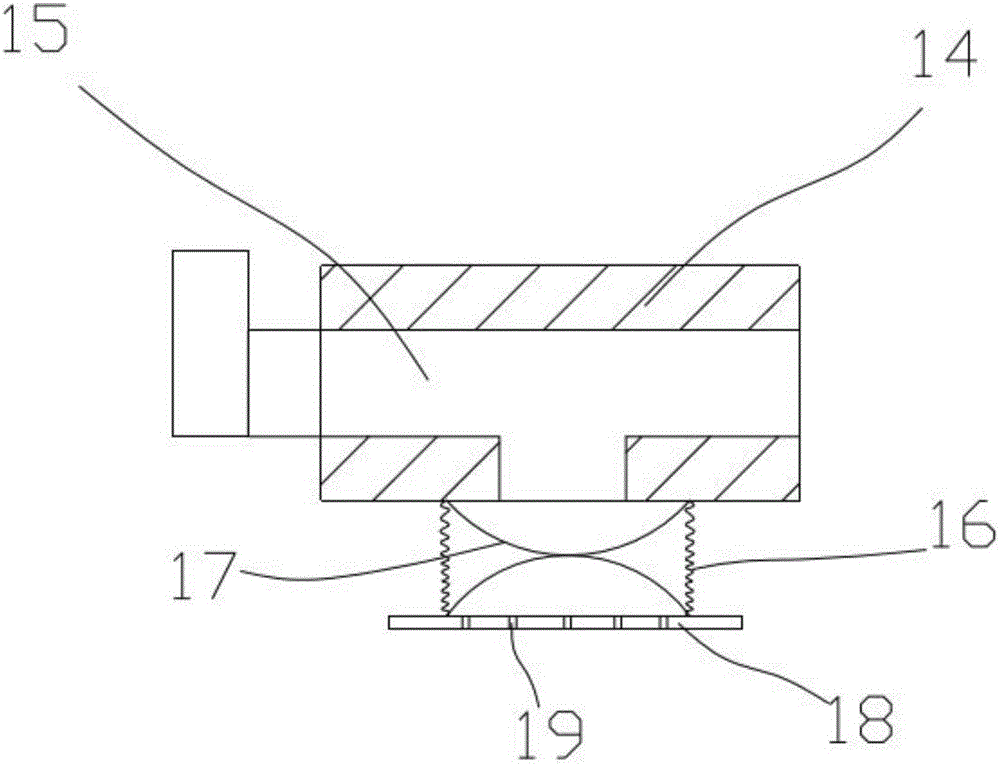

[0015] Such as figure 1 , figure 2 , image 3 As shown, the present invention proposes a FPC precision alignment machine, including a workbench 1, a four-axis robot 2 and a loading plate 3 are arranged on the workbench 1, and a number of placement components are arranged on the loading plate 3. Empty position, alignment stage, first vision camera 4, described first vision camera 4 is arranged upwards; Described alignment stage comprises support seat 5, and described support seat 5 is provided with carrier plate 6, and described carrier plate 6 is provided with two symmetrically arranged material loading positions 8 , and the lower part of the material loading positions 8 is connected with the first vacuum suction cup 7 .

[0016] The working method of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com