Test method of fire resistance of phosphorus gypsum and application

A test method and technology for fire resistance, which are applied in the field of fire resistance test of phosphogypsum, can solve problems such as unsuitable fire resistance, and achieve the effects of high accuracy, scientific fire resistance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

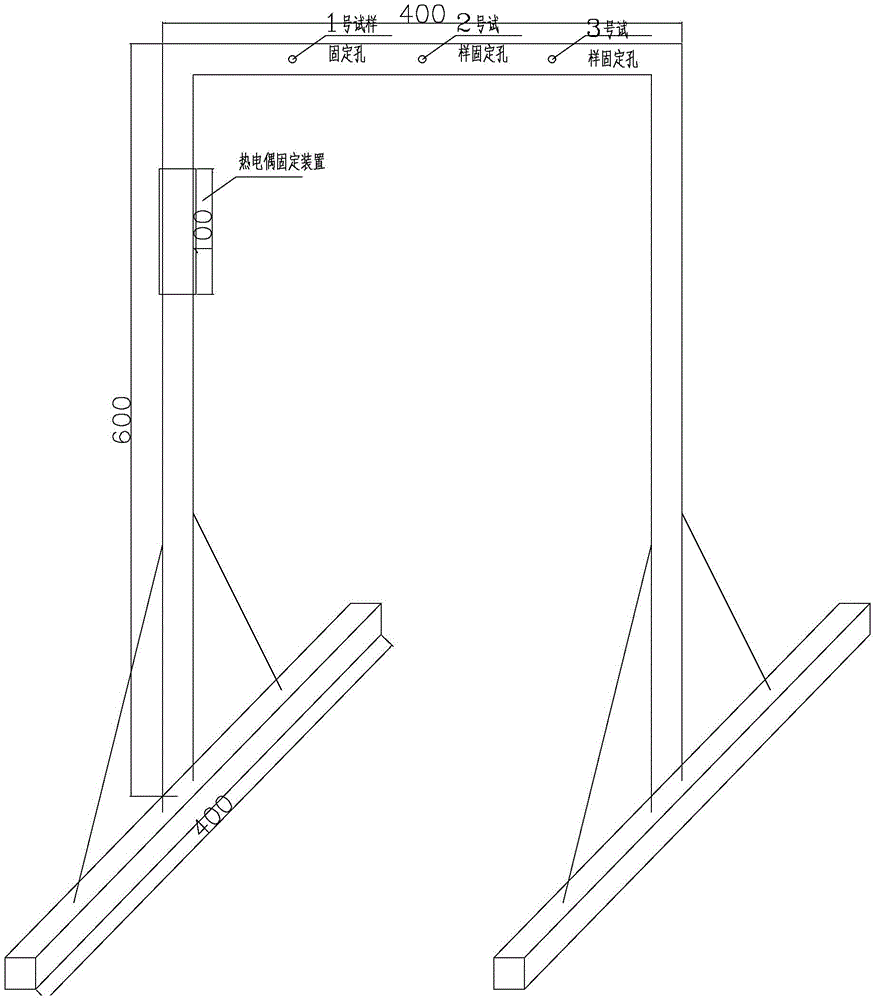

Image

Examples

Embodiment 1-7

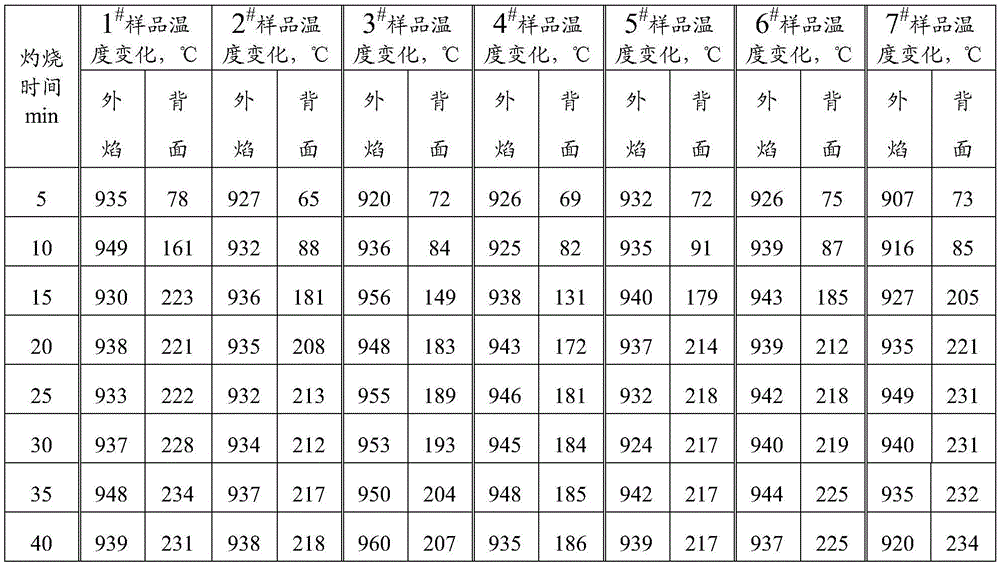

[0028] Use experimental method of the present invention to detect following 1 # ~6 # Widely used samples containing phosphogypsum and 7 # Fire resistance of desulfurized gypsum samples: 1 # —Hubei Yidu phosphogypsum; 2 # —Hubei Wuxue phosphogypsum; 3 # —Shandong Dezhou Phosphogypsum; 4 # —Mix the new phosphogypsum material in Chengdu, Sichuan and the old phosphogypsum material stored for one year at a ratio of 1:1; 5 # —The desulfurization gypsum of Zhuozhou Branch of Beixin Group Building Materials Co., Ltd. is mixed with Yunnan Kunming phosphogypsum at a ratio of 1:1; 6 # —Desulfurization gypsum and 4 # The sample phosphogypsum is mixed according to 1:1, 7 # — Taicang BNBM Co., Ltd. desulfurized gypsum (as a control).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com