Reinforced yielding U-shaped steel bracket

A technology of steel support and section steel, applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of collapse, roadway collapse, rigid damage of supporting steel frame, etc., to ensure effective support and avoid buckling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

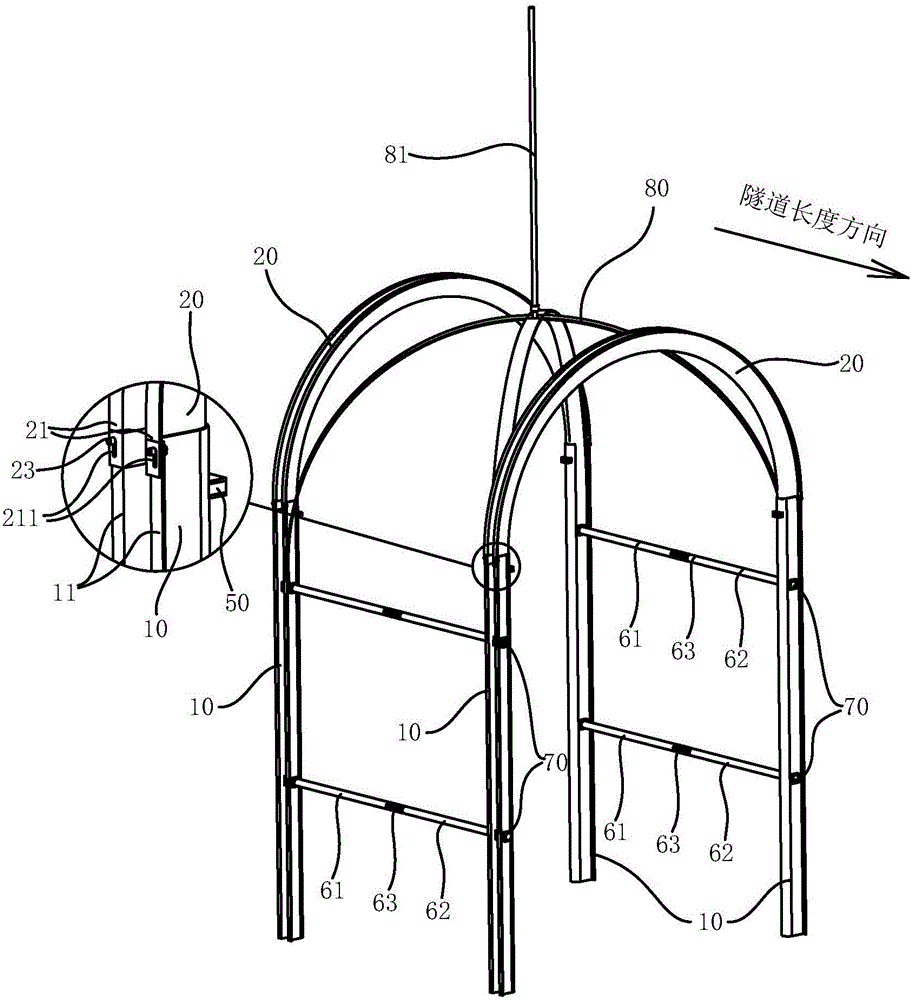

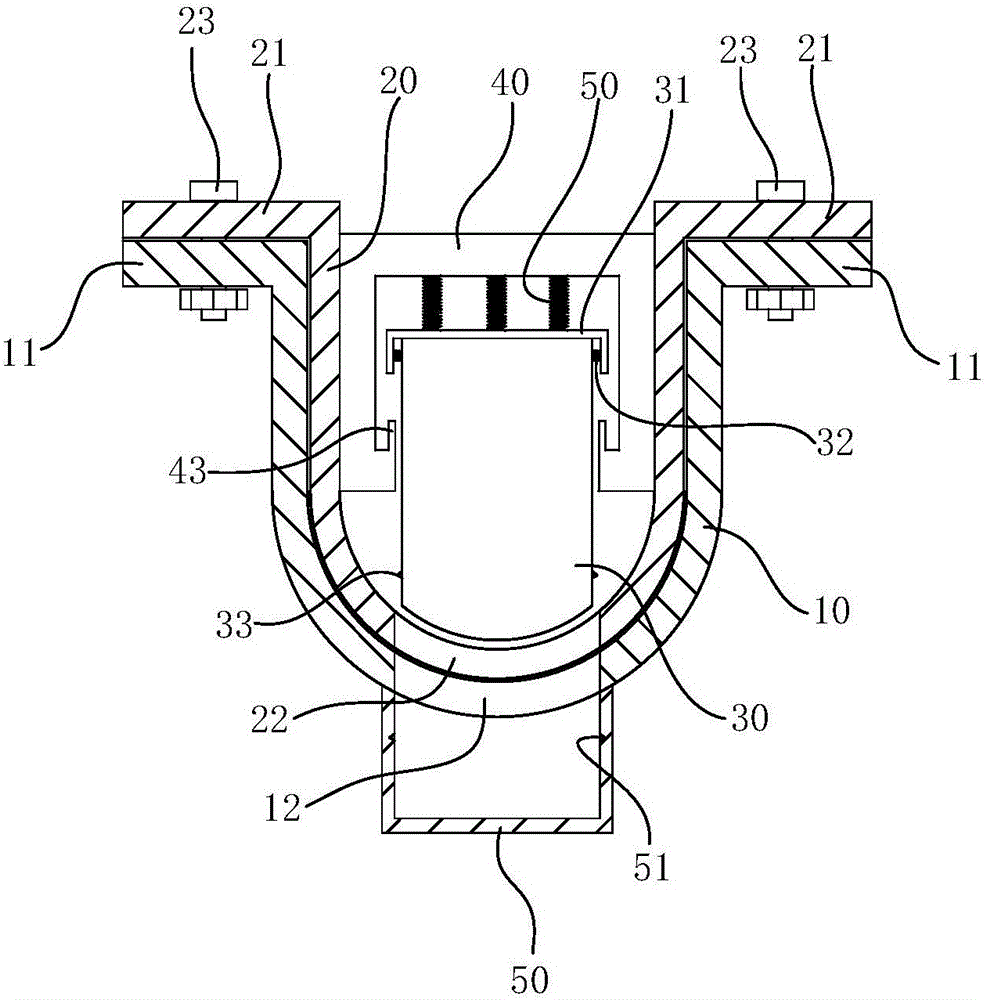

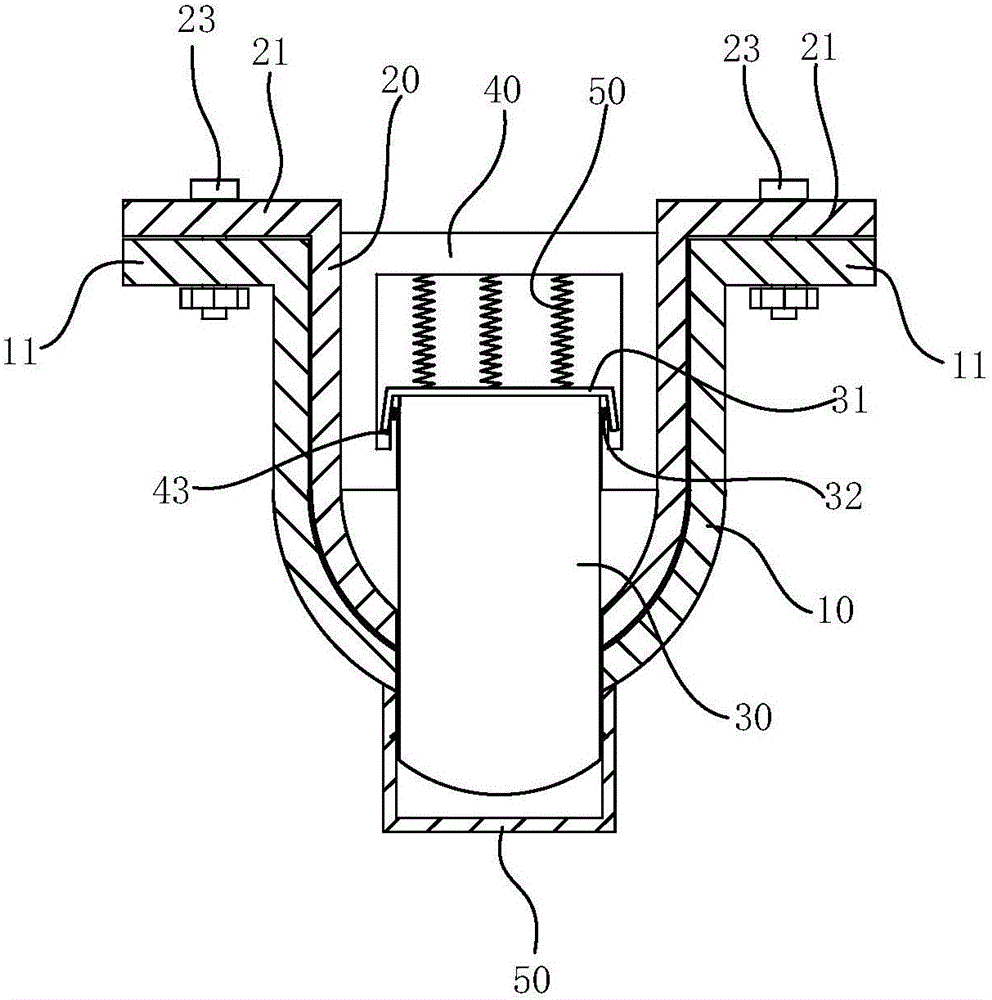

[0023] combine Figure 1 to Figure 8 , the present invention is further described:

[0024] A reinforced U-shaped steel support that can be pressed, including first supporting steel 10 arranged vertically on both sides of the roadway, and the upper end of the first supporting steel 10 is provided with a second supporting rock for supporting the arc-shaped top of the roadway. Supporting shaped steel 20, the second supporting shaped steel 10, 20 is bent into a curved structure, the two ends of the second supporting shaped steel 20 respectively form a vertically movable fit with the upper end of the first supporting shaped steel 10, the second supporting shaped steel The two ends of the two supporting shaped steel 20 and the first supporting shaped steel 10 are provided with a limited slip pressure relief mechanism, which is used to block the downward movement of the second support shaped steel 20;

[0025] combine figure 1 As shown, the U-shaped steel supports of the above str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com