Uniform gas-liquid mixing device used before underwater mixed transportation pumping inlet

A mixed-transport pump and inlet technology, which is applied to the components, transportation and packaging of elastic fluid pumping devices, pumps, etc., can solve economic losses, difficult maintenance and replacement, and large fluctuations in the gas content of pump inlets, etc. problem, to achieve the effect of low working intensity, high gas-liquid mixing efficiency, and automatic elimination of soda-water mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and example the present invention will be further described:

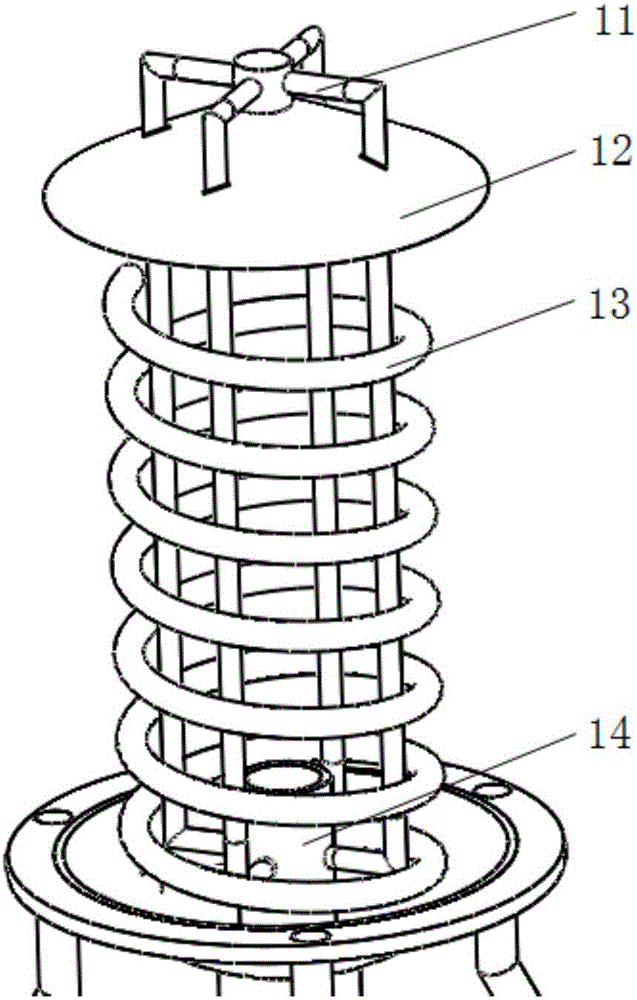

[0015] Such as Figure 1-4 As shown, the present invention is a gas-liquid homogenizing device used before the inlet of an underwater mixed pump, including a cylinder cover 1, an inlet pipe 2, a liquid level sensor 3, a bracket 4, a return pipe 5, a solenoid valve 6, and a tank body 7. Secondary mixing chamber 8, support shaft 81, blade 82, triangular fixing frame 83, outlet pipe 9, fixing belt 10, air guide pipe 11, gas collecting hood 12, heating wire 13, mixing chamber 14, air inlet hole 141, The cylinder cover 1 is fixed on the top of the tank body 7 by bolts and forms a sealed space with it, the tank body 7 is fixed on the bracket 4, and the inlet pipe 2 is fixed on one end of the tank body 7 and connected with the inside of the tank body 7 The sealed space is connected, and the other end of the inlet pipe 2 is connected with the wellhead outlet pipeline o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com