Resin mixture stirring system

A resin mixture and mixing system technology, which is applied to mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve problems such as unsafety, production methods, backward production tools and production processes, and poor product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will describe in detail with reference to the accompanying drawings in conjunction with the embodiments, so as to further explain the technical features and advantages of the present invention.

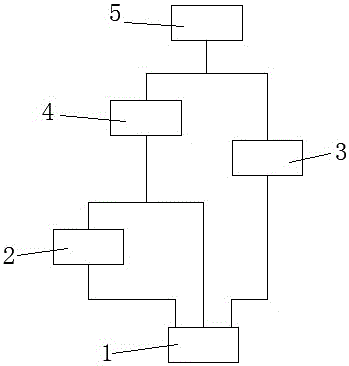

[0025] Such as figure 1 , 5 As shown, a resin mixture stirring system includes a stirring device 1, a batching supply device 2, a resin supply device 3, a pneumatic system 4 and an electric control system 5, and the output ends of the batching supply device 2 and the resin supply device 3 are respectively connected to the stirring device 1, the pneumatic system 4 is gas-connected to the stirring device 1 and the ingredient supply device 2 respectively, and the electric control system 5 is electrically connected to the pneumatic system 4 and the resin supply device 3 respectively. The present invention comprises stirring device 1 two ( Figure 5 Medium 1#, 2#), each set of various feeding systems (ingredient supply device 2, resin supply device 3), electric contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com