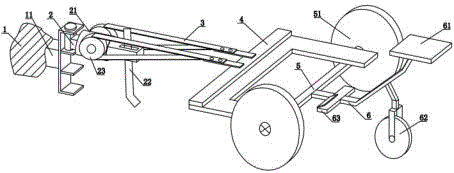

A dry land ride-on micro-cultivator with a frame assembly

A micro-tiller and assembly technology, applied in the field of micro-tillers, can solve the problems of lack of protection measures and easy occurrence of accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A seat micro tillage machine for dry land, comprising a micro tillage machine frame 1, an engine assembly, a braking mechanism, a handle assembly, a rotary tiller installed on the micro tillage machine frame 1 and a rear hanging body 11 And vehicle frame assembly; Wherein, described rotary cultivating cutter comprises cylindrical cutter cylinder and a plurality of groups of tillage knives that are arranged on described cutter cylinder; Described rear hanging body 11 comprises upper rear hanging body, middle rear hanging body and lower The rear hanging body, the groove walls of the upper rear hanging body, the middle rear hanging body and the lower rear hanging body are respectively provided with fixing slots, and fixing pins are arranged in the fixing slots, and the upper rear hanging body The connecting main shaft 2 is set in the hanging body, the upper and lower sides of the front end of the connecting main shaft 2 are respectively provided with main shaft rotating bea...

Embodiment 2

[0032] This embodiment is based on Embodiment 1. A bearing sleeve is set in the middle of the wheel main shaft. A main shaft bearing is arranged in the bearing sleeve. The wheel main shaft is arranged in the main shaft bearing. The seat mounting frame is welded on the bearing sleeve; the connection between the entire vehicle seat mounting frame and the wheel main shaft is flexible, which is convenient for users to operate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com