Driver of three-level IGBT power module and control method thereof

A technology of a power module and a control method, which is applied to the output power conversion device, the conversion of AC power input to DC power output, electrical components, etc. High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

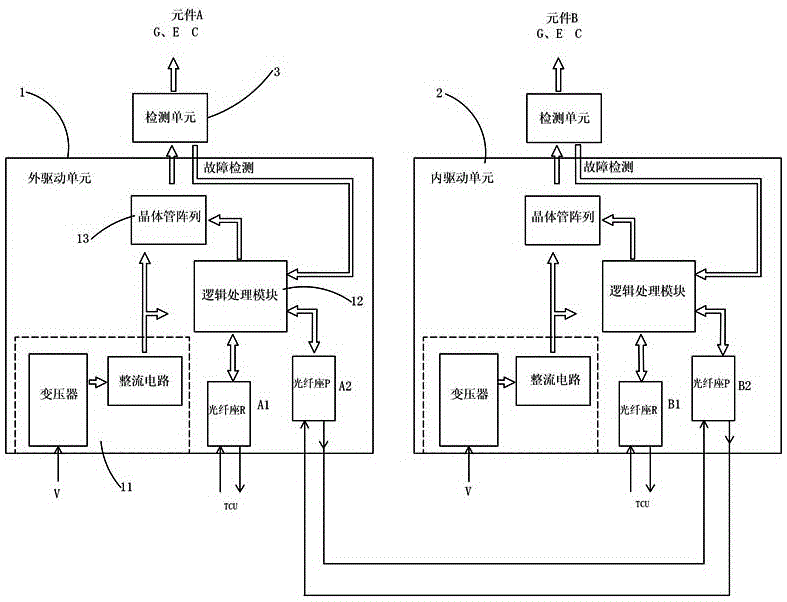

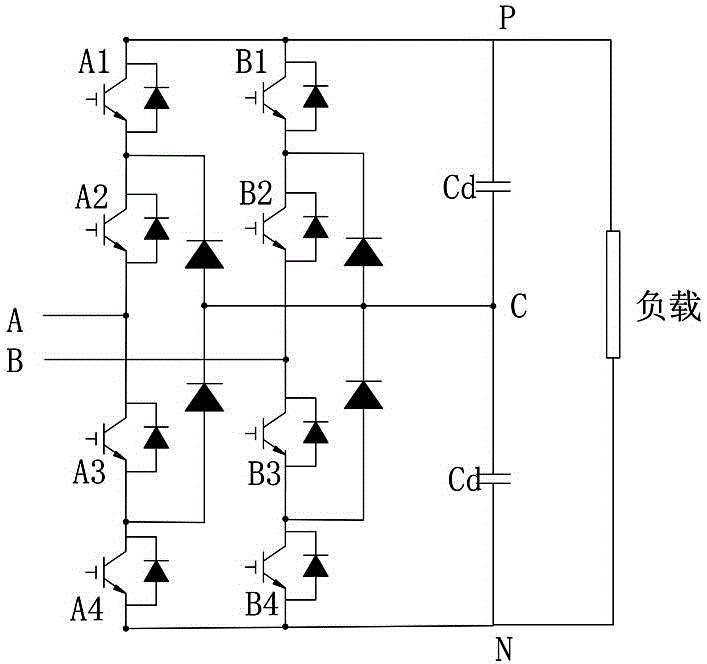

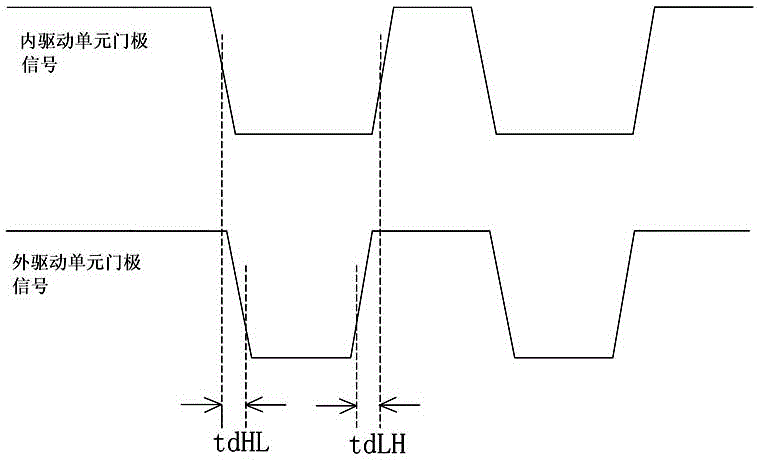

[0028] like Figure 1 to Figure 7 As shown, the driver of the three-level IGBT power module in this embodiment includes an outer drive unit 1 corresponding to the IGBT element outside the three-level IGBT power module, and an inner drive unit 2 corresponding to the IGBT element inside the three-level IGBT power module The external drive unit 1 and the internal drive unit 2 are connected in communication; the external drive unit 1 and the internal drive unit 2 are both provided with a corresponding detection unit 3, and are connected to the corresponding IGBT element signals through the corresponding detection unit 3. Among them, the three-level IGBT power module refers to the rectification circuit or inverter circuit whose bridge arm is connected in series by multiple power devices, such as figure 2 The bridge arm of the medium rectifier circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com