Driving pressure regulator

A pressure regulator and air pressure technology, which is applied in the direction of instruments, electric fluid pressure control, fluid pressure control, etc., can solve the problems of reduced sensitivity and precision of the pressure regulator, and achieve the improvement of automatic control level, timely sealing performance, and good performance. The effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

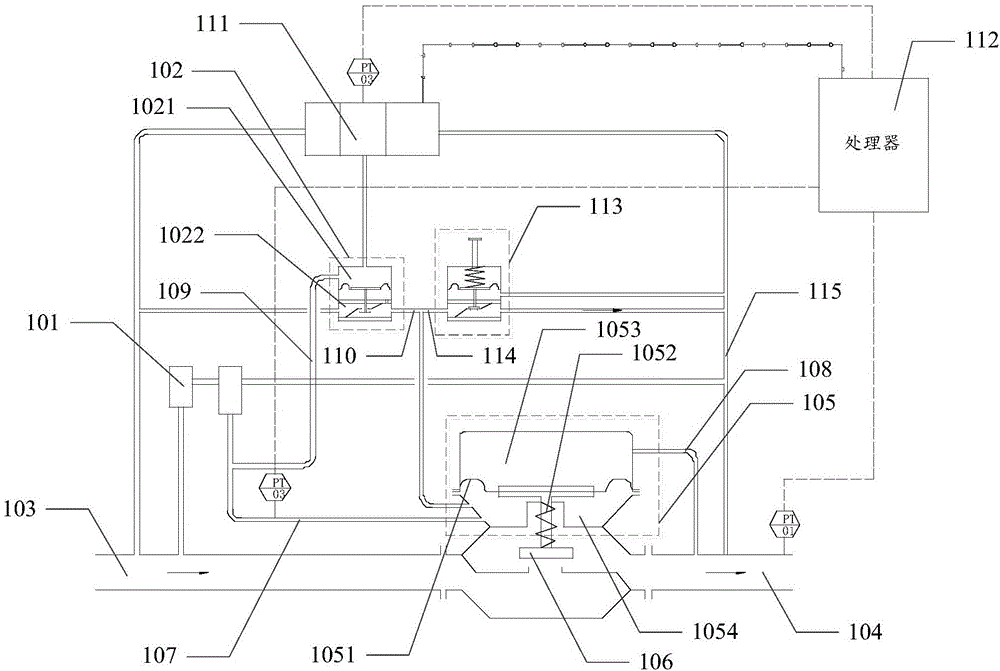

[0051] Please refer to figure 1 , Embodiment 1 of the present application provides a drive voltage regulator, including:

[0052] first pilot 101;

[0053] The second pilot 102 includes a first isolation membrane, a first pressure applying device, and a casing, the first surface of the first isolation membrane and the casing surround a first cavity 1021, and the first isolation membrane The second surface of the second surface and the housing enclose a second cavity 1022, the first surface is opposite to the second surface, and the first pressure applying device is arranged in the first cavity 1021;

[0054] The air pressure input end 103 is used to input the first air pressure; the valve seat is arranged on the passage of the first air pressure, including a valve port; the air pressure output end 104 is communicated with the air pressure input end 103 through the valve port; the driver 105, comprising a second isolation membrane 1051, an elastic device 1052 and a drive hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com