Implementing method of three-layer three-position injection molding for thick-wall part

A realization method and three-station technology, applied in the direction of optical components, other household appliances, household appliances, etc., can solve the problems of long injection molding cycle and limited scope of application, and achieve the effect of reducing injection molding cycle and improving the precision of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

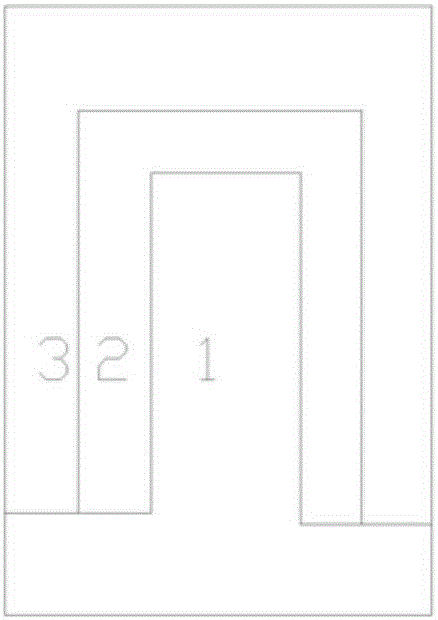

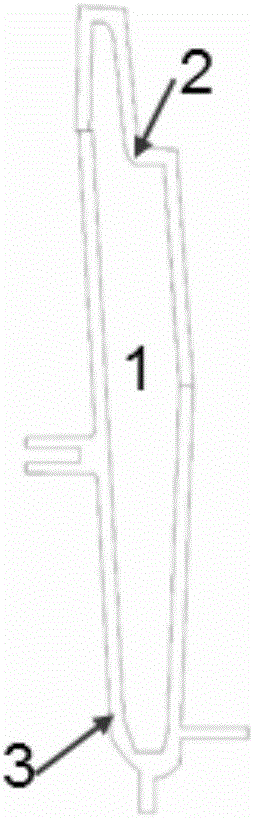

[0031] First inject the middle layer (sequence number 1), then inject the upper side (serial number 2) of the described middle layer periphery, and finally inject the lower side (serial number 3) of the described middle layer periphery; set the fixed mold and the movable mold to realize injection molding (see figure 2 );

[0032] The specific steps are:

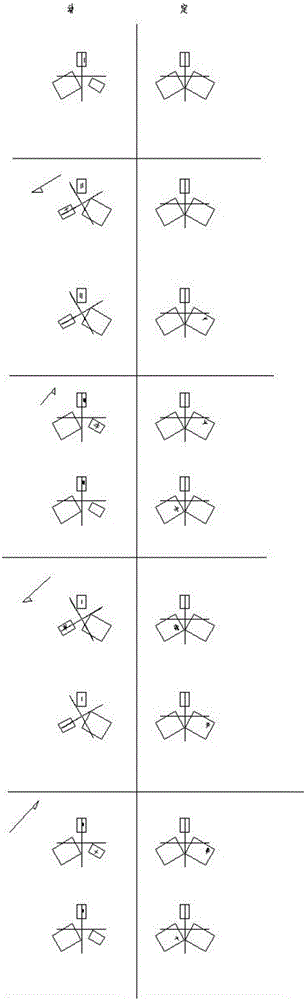

[0033] (1) No. 1 fixed mold and No. 1 moving mold are injected into the middle layer;

[0034] (2) The middle layer stays on the No. 1 movable mold side, rotates 120 degrees, and closes the mold;

[0035] (3) No. 1 fixed mold and No. 3 dynamic mold are injected into the middle layer; the middle layer of the mold opening is left on the side of No. No. fixed mold; reverse rotation 120 degrees;

[0036] (4) No. 1 fixed mold and No. 1 dynamic mold injection middle layer are opened and the middle layer is left on the side of No. 1 dynamic mold; No. 2 fixed mold and No. 2 dynamic mold are injected on the lower surface of the dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com