Temperature control device for adhesive supply system of single corrugating machine

A system temperature and control device technology, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of glue solidification, inability to glue, and block the pipe network in the horizontal pipe network, so as to reduce the impact on the environment and structure. Simple, waste-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

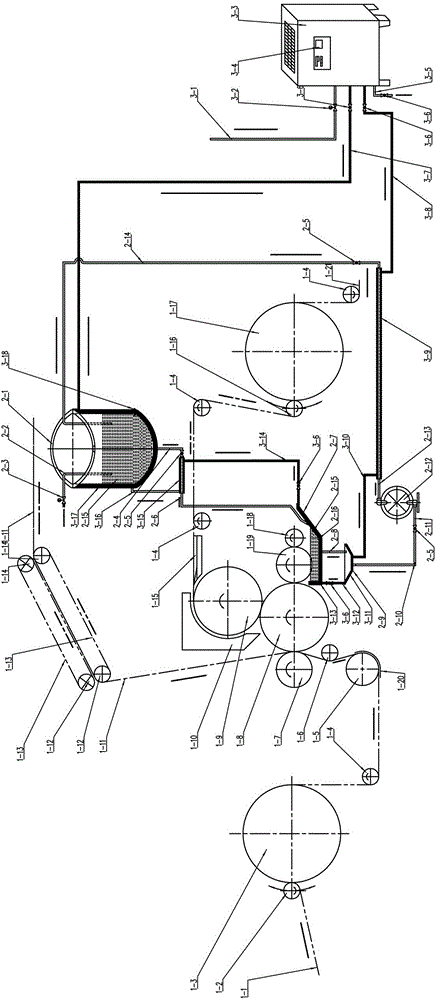

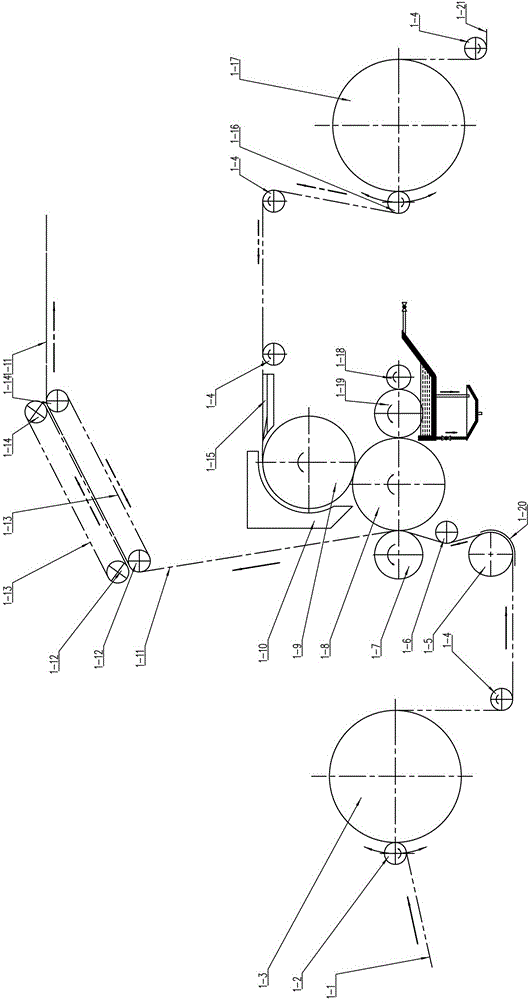

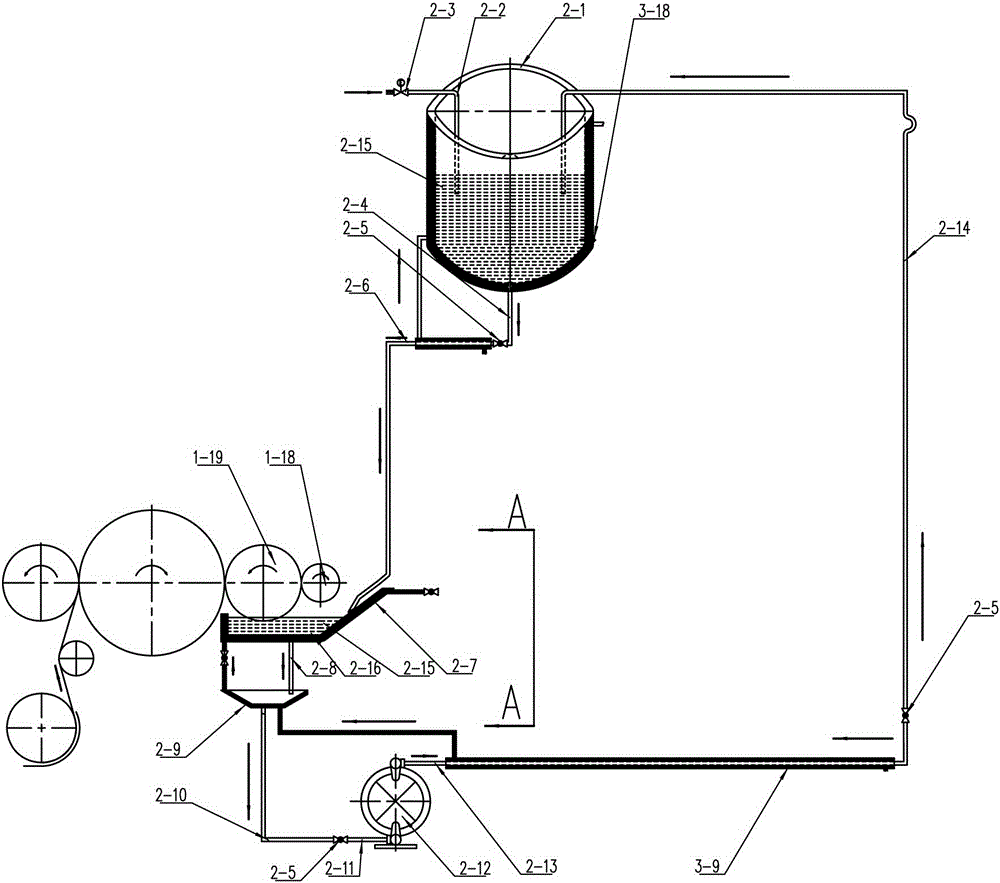

[0026] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] The temperature control device of the glue supply system of the single corrugating machine of the present invention image 3 Mainly include: such as Figure 4 As shown, water inlet pipe 3-1, electric control valve 3-2, water tank air-cooled chiller 3-3, parameter setting and operation interface 3-4, sewage pipe 3-5, ball valve 3-6, return pipe 3- 7. The first refrigerated water supply pipe 3-8, the second refrigerated water supply pipe 3-10, the first double-layer water storage pipe 3-9, the second double-layer water storage pipe 3-15, the interlayer water storage device 3 -11, the first connecting pipe 3-12, the second connecting pipe 3-14, the third connecting pipe 3-16, the interlayer water storage device of the rubber disc 3-13, the interlayer water storage device 3-17 of the rubber storage barrel, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com