A low-rank coal slime flotation collector and its application

A coal slime flotation and collector technology, which is applied in flotation, solid separation and other directions, can solve problems such as difficulty in popularization and application, potential safety hazards, poor operability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

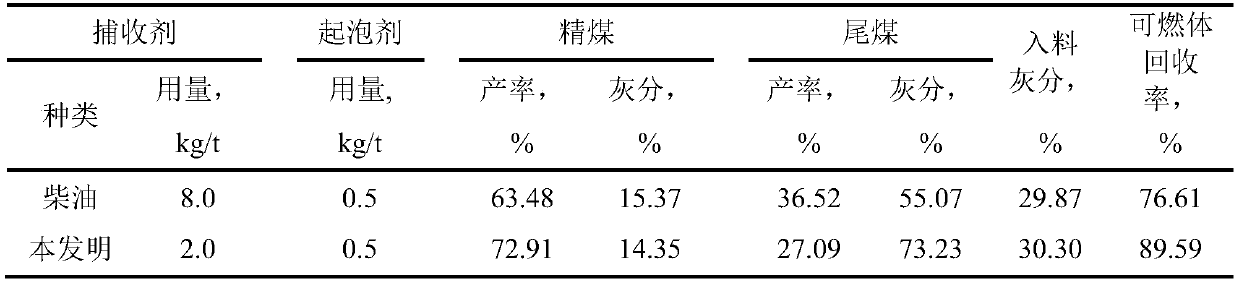

[0032] Example 1: Coal slime properties: The coal sample is from Shuozhou long-flame coal, and the coal slime has a high inner ash content, and the ash content of the incoming material is 30%. The particle size of the coal sample is relatively fine, and the -0.074mm particle size coal slime accounts for 60% of the coal sample.

[0033]Operating conditions: During flotation, first add a certain amount of pre-configured flotation collector (configured according to the optimal ratio) to the flotation pulp, and then add a certain amount of foaming agent 2-octanol, the pulp after adding the agent Flotation separation (pulp concentration: 80g / L) is carried out after stirring and pulping to obtain flotation clean coal and flotation tailings. Table 1 shows the flotation comparison results of the medicament of the present invention and common collector diesel oil. The proportion of the flotation collector is 70% of diesel oil, n-octanoic acid (8%), butyl benzoate (6%), diisobutyl keto...

Embodiment 2

[0037] Example 2: Coal slime properties: The coal sample is from Fugu weakly caking coal, and the ash content of the raw coal is 45%. -0.074mm particle size coal slime accounts for 65% of the coal sample.

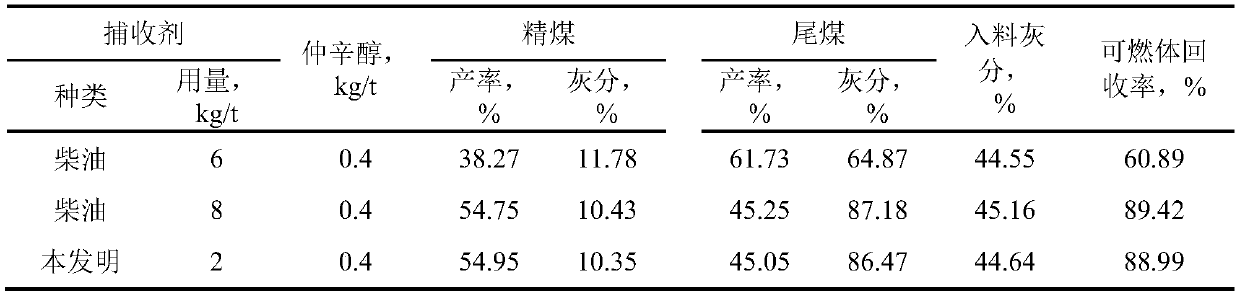

[0038] Operating conditions: During flotation, first add a certain amount of pre-configured flotation collector to the flotation pulp, and then add a certain amount of foaming agent 2-octanol. After adding the agent, the pulp is stirred and adjusted for 2 minutes. A flotation separation can get the corresponding flotation effect. The flotation comparison results of the agent of the present invention and common collector diesel oil are shown in Table 2. The proportion of the flotation collector is 60% of diesel oil, n-octanoic acid (12%), butyl benzoate (8%), diisobutyl ketone (8%), and n-valeraldehyde (12%).

[0039] Table 2 Comparison of diesel oil flotation index between collector of the present invention and common collector (Fugu weak sticky coal)

[0040]

[0041...

Embodiment 3

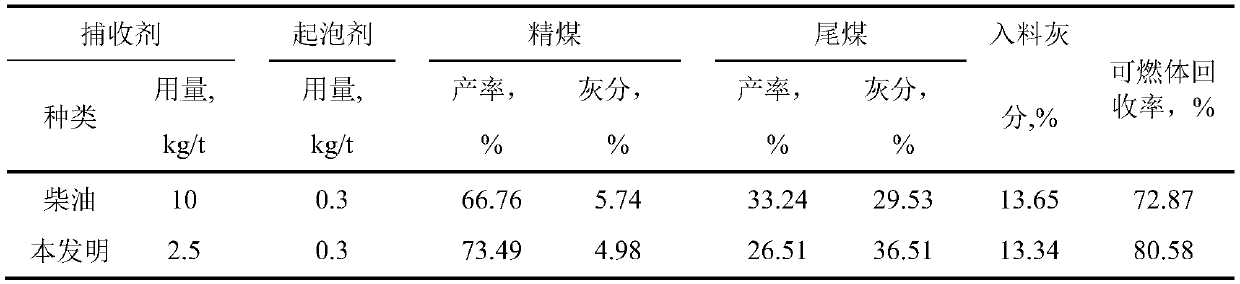

[0042] Example 3: Coal slime properties: It is derived from Shendong Changyan coal, the ash content of coal slime is 13%, and the particle size of -0.074mm accounts for 70%.

[0043] Operating conditions: During flotation, first add a certain amount of pre-configured flotation collector to the flotation pulp, and then add a certain amount of foaming agent 2-octanol. After adding the agent, the pulp is stirred and adjusted for 2 minutes. A flotation separation can get the corresponding flotation effect. The flotation comparison results of the agent of the present invention and common collector diesel oil are shown in Table 3. The proportioning of the flotation collector is 68% of diesel oil, n-octanoic acid (8%), butyl benzoate (4%), diisobutyl ketone (12%), and n-valeraldehyde (8%).

[0044] Table 3 collector of the present invention and common collector diesel oil flotation index comparison (Shendong Changyan Coal)

[0045]

[0046] As can be seen from Table 3, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com