A combiner placement support assembly

A combiner and assembly technology, applied in circuits, waveguide-type devices, electrical components, etc., can solve the problems of collision and impact of combiner placement, and achieve the effect of getting rid of installation restrictions, wide application scope, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

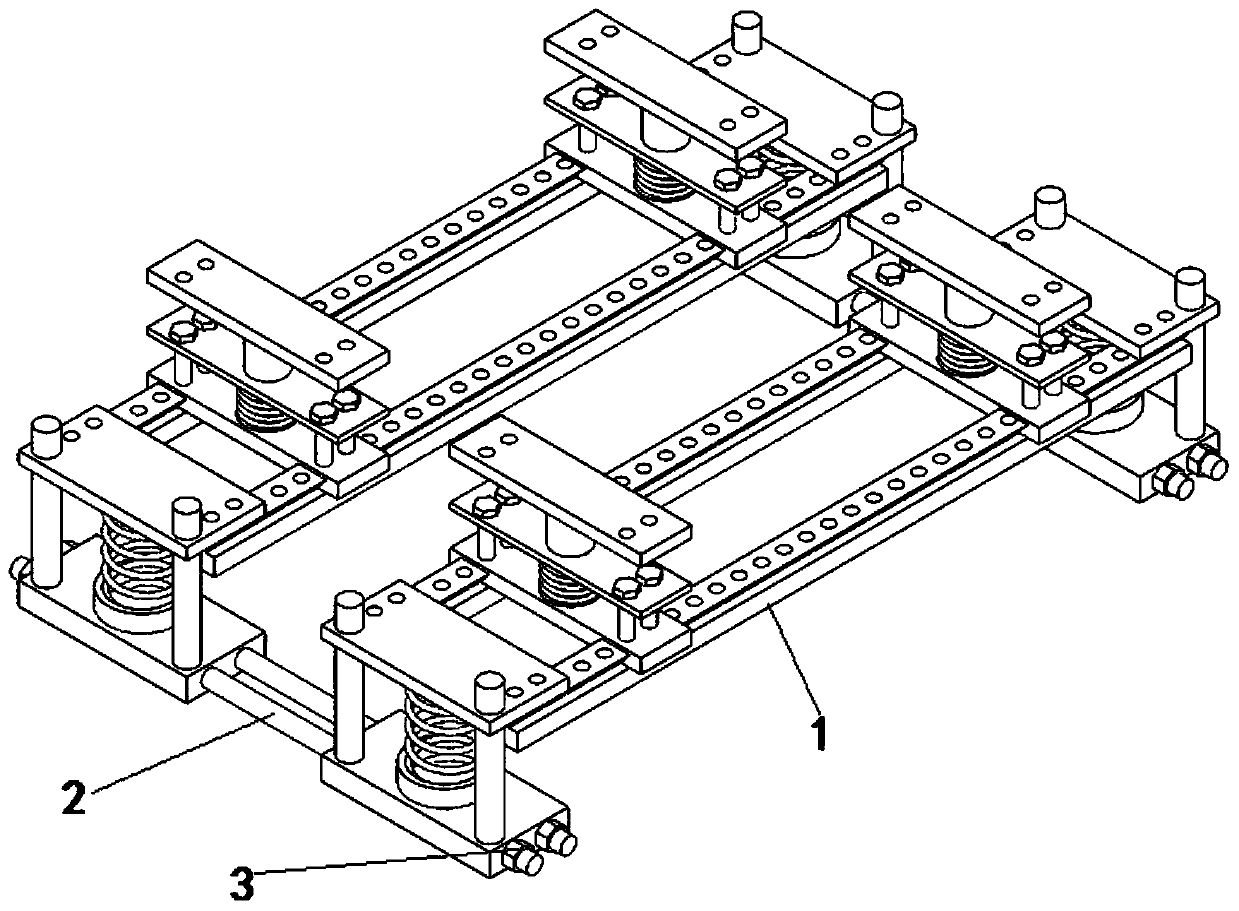

[0022] Such as Figure 1 to Figure 5 The illustrated support assembly for placing a combiner includes two support mechanisms 1, the two support mechanisms 1 are connected by a screw 2, and locknuts 3 are fixed at both ends of the screw 2;

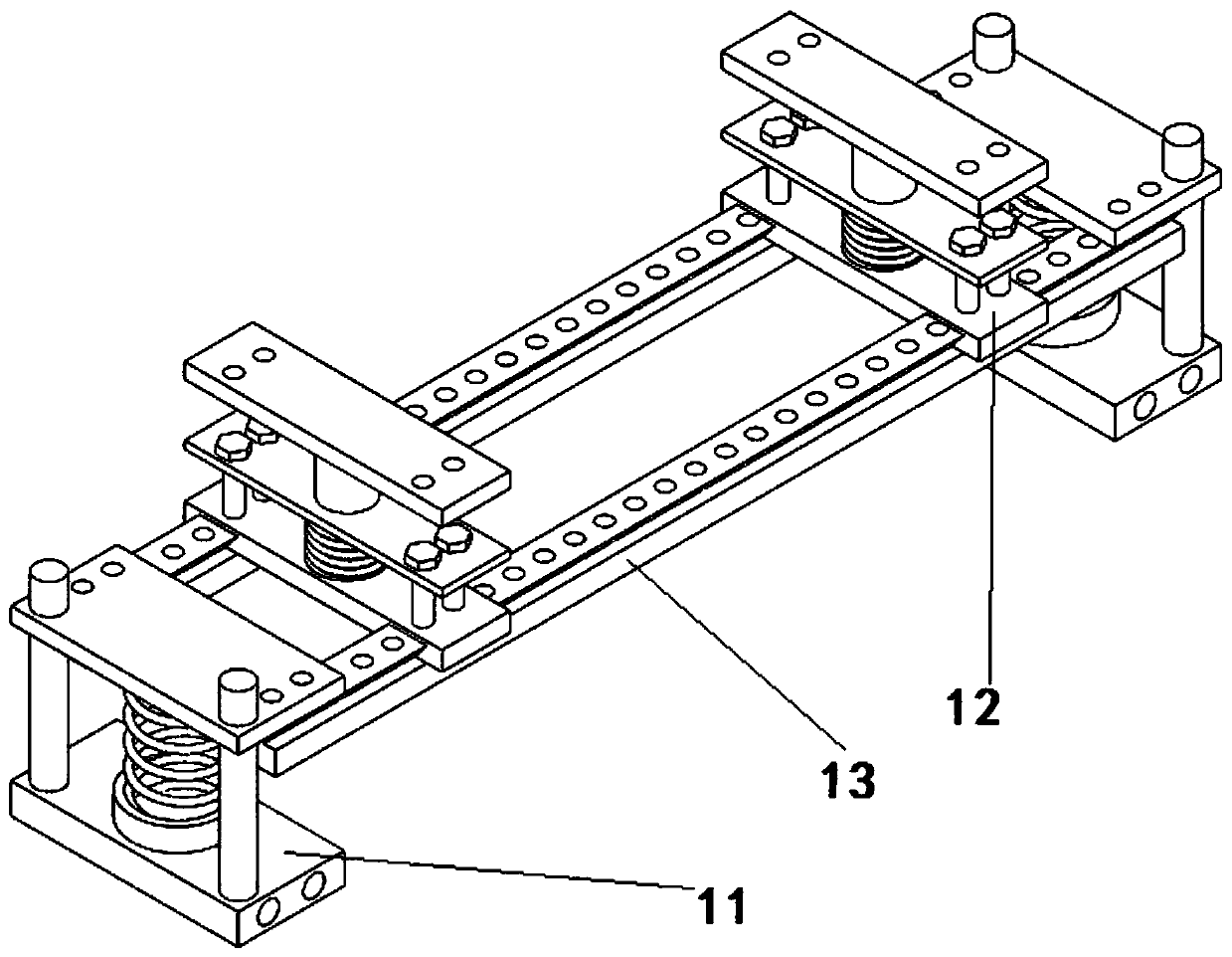

[0023] The support mechanism 1 includes two slide rails 13 parallel to each other, a shock absorbing mechanism 12 is installed on the slide rails 13, and mounting seats 11 are connected to both ends of the slide rails 13;

[0024] The mounting seat 11 includes a bottom plate 111, a slide bar 112 is fixed at both ends of the bottom plate 111, a mounting tube 113 is fixed in the center of the surface of the bottom plate 111, a connecting plate 116 is slidably installed on the sliding bar 112, a main spring 115 is installed in the mounting tube 113, and the bottom plate 111 A first threaded hole 114...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com